What Is a Buffing Service?

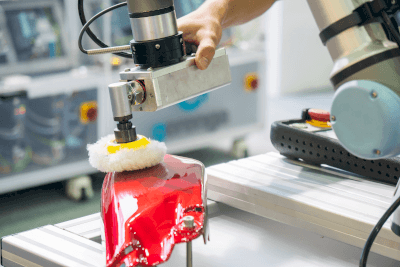

A buffing service is a method used to smooth surfaces by eliminating irregularities. This process involves applying abrasives to a buffing wheel, typically made of cloth or similar materials, which then rotates to polish the object.

A buffing service is a method used to smooth surfaces by eliminating irregularities. This process involves applying abrasives to a buffing wheel, typically made of cloth or similar materials, which then rotates to polish the object.

Suitable for both metal and plastic resin materials, buffing services enhance surface properties, providing chamfering, improved surface roughness, mirror finishes, and slipperiness. The buffing process, often performed before and after plating, allows for adjustable levels of finishing by varying the buffing materials and abrasives.

Uses of Buffing Services

Buffing services are essential for smoothing material surfaces, adding luster, removing burrs and chamfers, and enhancing surface finish post-plating. These services are particularly vital when specific surface roughness is required.

Typically, buffing employs materials like cloth, linen, wool, or sponge—softer than grinding wheels. Buffing grains are graded by numbers, such as “#00”; higher numbers indicate finer grains and a higher luster on the polished surface.

Principle of Buffing Services

Buffing works on the principle of micro-cutting action from abrasive grains. This action, combined with high-speed rotation-induced temperature rise (friction), produces a lustrous finish through both mechanical surface flow and the chemical impact of the abrasives.

The buffing process typically includes three stages: Rough Polishing, Intermediate Polishing, and Finishing Polishing.

- Rough Polishing: Aimed at removing surface scratches, rough polishing is often the initial stage of buffing.

- Intermediate Polishing: Following rough polishing, this stage enhances the material’s luster. Most buffed products are completed at this stage.

- Finishing Polishing: This final stage is used for achieving semi-mirror or mirror finishes on the material’s surface.

The chosen process depends on the required finish quality; consultation with the processing manufacturer is recommended.

As outlined, buffing services significantly enhance product quality, contributing to improved durability and lifespan.