What Is a Slug?

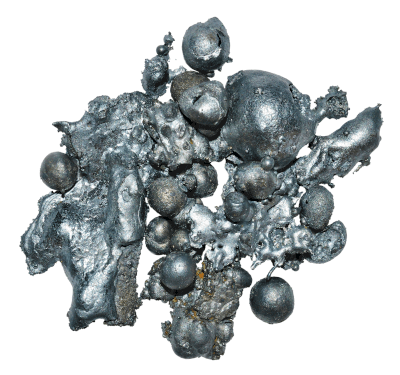

Slugs are byproducts generated during the melting and refining of metals such as iron and copper.

It is produced when impurities contained in metal ores dissolve and react with oxides such as lime and silica. In addition to metals, they are sometimes used as raw materials for cement and glass, or reused as materials for railroads and pavements. The reuse of slug is expected to make effective use of resources and reduce waste, but since it can cause environmental pollution, it must be treated appropriately in the manufacturing process.

Uses of Slugs

1. Raw Material for Cement

Slugs are materials that mainly contain oxides such as silica, alumina, and iron oxide. Silica, alumina, and iron oxide are used as raw materials for cement. When heated together with lime, the main ingredient of cement, Slugs undergo a chemical reaction and become a solidified material. Slugs can be used in cement to remove oxides and improve the strength of the cement.

Silica is a compound called silicon oxide whose chemical formula is SiO2. Alumina is a compound called aluminum oxide with the chemical formula Al2O3.

2. Raw Materials for Glass

It mainly contains oxides such as silica and alumina, which are used in glass production because these components are similar to silica acid and alumina, which are major components of glass.

3. Material for Road and Railroad Substructures

The high density and durability of glass make it an ideal material for use in road and rail substructures. Its low permeability also allows it to drain well, making it an excellent drainage material for road and railroad construction.

4. Raw Material for Construction Materials, Limestone, Etc.

Slugs contain components such as silica, alumina, iron oxide, and calcium, which are used in building materials such as limestone and cement. Being a solid, it can be used as it is when used as a building material.

5. Stabilization of Roadbeds

Slugs are also used to stabilize roadbeds for roads and railroads. Since it is solid, it can be mixed with soil to improve the stability of roadbeds. It can also improve soil compaction due to its high density.

6. Soundproof Walls, Protective Walls, and Pavement Materials

Due to its excellent acoustic properties, it is sometimes used for soundproofing walls, protective walls, and pavement materials.

7. Soil Conditioner

Slugs are also used as soil conditioners in agriculture. It is used as a fertilizer in agriculture because it neutralizes soil acidity and provides nutrients. The iron and calcium content in Slugs is also used as a nutrient for crop growth.

8. Ground Improvement Material

Slag is suitable for ground improvement because it increases the density of soil and improves its compressibility. As a ground improvement material, it is also used in road and railroad construction.

9. Environmental Purification Material

The components contained in slugs are effective in adsorbing and removing pollutants. For example, it is sometimes used for water purification. Slugs contain metal ions such as iron and aluminum, and these ions are used in the treatment necessary for water purification.

10. Raw Material for Manufacturing Recycled Iron Powder

Slugs are also used as a raw material for the manufacture of recycled iron powder. Recycled iron powder is an iron powder produced by reusing waste materials such as iron scale and steel scrap generated in the iron manufacturing process, and is used as a raw material for manufacturing recycled iron powder.

Properties of Slugs

Slugs are produced during the process of melting metal ores at high temperatures to separate the metal from the impurities. The basic process is as follows

1. Melting of Metal Ores

Melting metal ores at high temperatures initiates the dissolution process to separate metals from impurities. Impurities contained in the metal ore have a lower melting point than the ore itself, so they tend to dissolve during melting.

2. Oxygen Blowing

The molten slugs contain oxides as well as metals. When oxygen is blown in to remove these oxides along with impurities, the impurities are oxidized and become slugs, making them easier to dissolve.

3. Reaction of Impurities

After impurities are oxidized by oxygen blowing and dissolved into the molten slag, they react with additives such as lime and silica to form slugs. This reaction leaves the slugs as a liquid with properties different from those of metals.

4. Extraction of Slugs

Since slugs are lighter than metal, they float on the surface in liquid form, which makes it easier for slugs to separate from metal. After the metal and slugs are separated, the slugs are cooled and solidified, and processed as a byproduct.

Types of Slugs

Slugs come in a variety of types depending on the type of metal ore and refining method, and there are several ways to classify them. Below are some of the typical classification methods for Slugs.

1. Classification by Material Type

Since slugs are produced from different materials depending on the type of metal ore, they may be classified based on their materials. Typical slug materials include iron slugs, copper slugs, lead slugs, zinc slugs, and aluminum Slugs.

2. Classification by Chemical Composition

Slugs are sometimes classified based on their chemical composition because they have different chemical compositions depending on impurities and additives in the ore. Examples include lime slugs, silica slugs, alumina slugs, and manganese slugs.

3. Classification by Manufacturing Process

Slugs are by-products generated during the metal ore refining process and may have different properties depending on the manufacturing process. For example, blast furnace slugs are generated in the blast furnace steelmaking process, while molten slugs are generated in the melting furnace coppermaking process. Thus, Slugs may be classified based on the manufacturing process.

Types of Slugs

Typical slugs, their generation processes, and reuse methods are shown in the table below.

| Name of Slugs | Generation Process | Reuse Method |

|---|---|---|

| Iron Slugs | Produced by melting metallic ores at high temperatures and blowing oxygen into them | Used as raw material for cement and concrete, material for road and railroad substructures, and alternative material for gravel and pavement materials |

| Copper Slugs | Produced by melting ores at high temperatures and blowing oxygen into them during the copper manufacturing process | Used as cement, pavement material, abrasive, and road substructure material |

| Aluminum Slugs | Produced by melting metal ores containing aluminum at high temperatures and blowing oxygen into them | Used in cement, soil conditioners, pavement materials, and the manufacture of metal parts |

| Silicon Slugs | Generated in the process of reducing silicon ore | Used as an additive in the manufacture of cement, limestone, soil conditioners, building materials, and steel production |

| Steel Slugs | Generated in the process of steel manufacturing | Raw material for cement and concrete, material for road and rail substructures, substitute material for gravel, additive to remove impurities during steel refining, fuel for steelmaking processes |

| Zinc Slugs | Generated in the smelting process of zinc ore | Cement, soil improver, material for road substructures, metal recycling |

| Nickel Slugs | Generated in the refining process of nickel ore | Cement, soil improver, material for road substructure, metal recycling |

Other information on Slugs

1. Utilization of Slugs

In addition to metal refining, slugs are used in a wide range of fields, including environmental measures, construction, and agriculture.

For example, slugs are sometimes used as a soil conditioner. Slugs contain lime, iron, and other components that adjust the pH value of the soil and increase the absorption of nutrients in the soil. Slugs also improve air permeability and drainage, which can promote the growth of crops.

Furthermore, it is effective in environmental measures. Slugs are sometimes used as adsorbents for acid rain and soil pollutants. Lime slugs are particularly effective in neutralizing acid rain and helping to protect the environment.

In the construction field, slugs are used as raw materials for road and railroad substructure materials and building materials. It is attracting attention as an environmentally friendly material with excellent durability and longevity.

2. JIS Standards Related to Slugs

JIS (Japanese Industrial Standards) related to slug aggregate includes the following slug aggregate is a type of construction material made from molten slugs generated during the smelting of ferrous and nonferrous metals.

- JIS A 5011 (slug aggregate for concrete)

Blast furnace slugs aggregate

Ferronickel slug aggregate

Copper slugs Aggregate

Electric furnace slug aggregate - JIS A 5012 (Blast furnace slugs fine aggregate for concrete)

- JIS A 5015 (Steel slugs for roads)

- JIS A 5021 (Recycled aggregate H for concrete)