What Is an Acrylic Product?

Generally speaking, the term “acrylic” refers to acrylic resin or acrylic fiber.

Although both are called “acrylic,” they have different chemical structures and are completely different from each other.

Acrylic resin was industrialized around 1934 and is still used today as a raw material for plastics in a variety of applications.

Acrylic fiber, on the other hand, is also well-known and was developed around 1950. It has properties similar to wool and is used in clothing such as sweaters.

Uses of Acrylic Products

First of all, acrylic products were initially used for military applications, such as in the canopies of fighter aircraft.

Today, however, acrylic products are used in a wide range of applications, including lighting fixtures, construction materials, electronic components, industrial materials, and acrylic paints.

On the other hand, acrylic products with properties similar to wool are used for sweaters, knitted hats, blankets, and carpets.

In addition, acrylic fiber is used in the industrial field as a filtering material for filtration equipment and in the construction field as a substitute for asbestos.

Characteristics of Acrylic Products

Acrylic products are made by polymerizing organic compounds called methacrylic esters or acrylic esters.

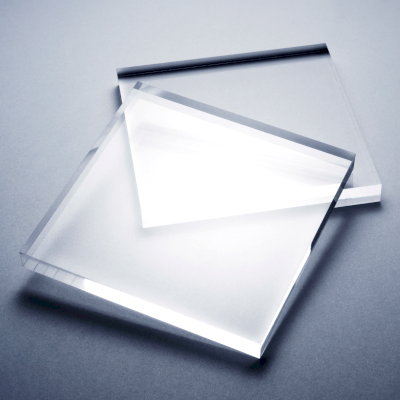

The manufactured acrylic products are durable, heat resistant, easy to process, and impact resistant. However, their greatest merit is their transparency.

For this reason, acrylic products are made into panels and applied to aquariums.

The disadvantage is that the surface is easily scratched. For this reason, it is also applied as a resin for raw materials for paints. However, the paints produced are sold with the claim that they are inexpensive and have short durability.

Acrylic fiber is produced by taking an organic compound called acrylonitrile as a starting material and polymerizing it with other organic compounds.

Those made from 85% or more polymerization of polyacrylonitrile through this polymerization are called acrylic fibers, while those made from 35 to 85% and containing vinyl chloride or vinylidene chloride are called acrylic-based fibers.

The advantages of acrylic products are lightness, moisture retention, and good dyeability; the disadvantages are that they are prone to static electricity.