What Is Flux?

Flux is a soldering agent made mainly from resin.

Flux is an organic substance found in trees, most famously pine resin, which is a sticky liquid. The flux is made by mixing the resin with an activator.

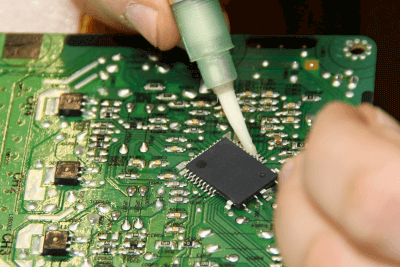

When electronic components are mounted on a circuit board, a soldering iron is used to melt a long, thin piece of metal called solder to form a joint.

Flux is mixed with this solder.

If the flux is not used, not only will the product not be completed, but it will also result in a large number of defective products, which could lead to an accident.

Uses of Flux

The main use of flux is for bonding electronic components.

If you look at an electronic circuit board, you will see many rounded pieces of silver metal. This metal is solidified from the solder that has been melted by heat, and flux is added to the solder to keep it from oxidizing and forming.

There are also fluxes for joining metals, which are mixed with solder when metals are soldered together.

There is also flux for stainless steel. Stainless steel forms a passive film on its surface. A flux is used to remove this passive film.

Characteristics of Flux

The number one feature of flux is that it allows the solder to form on the electronic board without degrading its quality.

When solder is melted, the work area is often at room temperature, and the melted solder is highly heated. This causes the metal surface of the melted solder to oxidize, resulting in defective electronic substrates.

The role of flux is to inhibit the oxidation of solder, and a film of flux is formed to cover the metal surface.

In addition, the solder itself has high surface tension and quickly becomes spherical when melted in the normal way. To prevent this from happening, flux is added to lower the surface tension of the solder.

On the other hand, the disadvantage of flux is that it remains attached to the solidified metal and remains on the electronic board.

Since flux is intended to condition the basic solder, it is unnecessary once the solder has solidified successfully.

However, if flux remains, the PCB will be defective, and the PCB will need to purchase a special cleaning agent to remove it, or consider the use of a large cleaning machine.