What Is a Gauge Block?

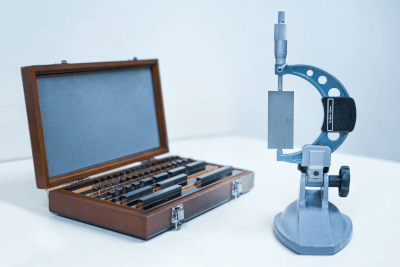

A gauge block is defined as “an end-device made of durable material, having a rectangular cross-section and two parallel measuring surfaces,” which are in close contact with other gauge blocks or auxiliary bodies (reference plane). (End-degree device: a reference that expresses dimensions in terms of the distance between two parallel surfaces)

Generally, a gauge block consists of several rectangles. Each rectangle has the same dimensions in length and width, but different thicknesses, which can be superimposed to produce any desired dimension in the direction of thickness.

Uses of Gauge Blocks

Gauge blocks are manufactured under very strict dimensional control and are used to measure length standards.

Specifically, gauge blocks are used as dimensional measurement standards when assembling precision instruments, or for measuring the accuracy of calipers, micrometers, and other instruments.

When assembling precision instruments, there are cases in which instructions are given on the gap to be secured between members. In such cases, multiple gauge blocks can be placed on top of each other and applied to the gap to create the desired dimension.

Features of Gauge Blocks

Gauge blocks have the following features:

- Accurate dimensions

- They adhere well (ringing) to other gauge blocks and auxiliary bodies.

- Hard material and excellent abrasion resistance

- Excellent dimensional stability and little dimensional change over time

- The thermal expansion coefficient is known

- Rust-resistant

- Of the six rectangular surfaces, two precisely adjusted surfaces are used as measuring surfaces.

The above features indicate that the product is rigorously manufactured. Therefore, the following grades are determined according to the quality level:

- Grade K (ultra-precision): For calibration and research of gauge blocks

- Grade 0 (precision): Calibration of high-precision measuring instruments

- Grade 1 (inspection): Calibration of measuring instruments

- Grade 2 (for machine tools): Calibration of calipers, etc.

Naturally, the higher the grade (the more precise), the higher the price, and the more careful handling is required.

Although gauge blocks are precisely made, it is necessary to consider how to use as few blocks as possible to form the desired dimensions to minimize errors.