What Is a Dry Heat Sterilizer?

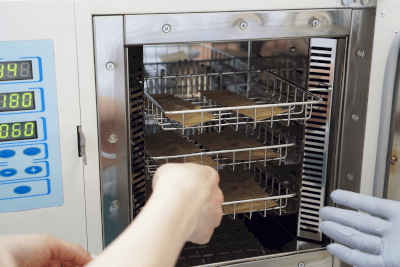

A dry heat sterilizer is a device that uses heated dry air to kill microorganisms attached to various instruments.

Dry air of 100°C or higher is generated in an electric oven, and instruments are sterilized by exposing them to the air for a certain period.

Sterilization conditions (temperature and time) are set in consideration of the heat resistance of the target bacteria. The instruments themselves must also be highly heat resistant.

Either the batch or continuous method described below is used to expose the instruments to dry air.

When handling a large variety of instruments, the batch method is used to perform the sterilization process for each instrument.

Uses of Dry Heat Sterilizers

Dry heat sterilizers are often used for glassware, ointments, and powders that require sterilization.

For example, if microorganisms are introduced into a cell culture medium, they may multiply due to the nutrients contained in the medium.

As a result, the cell culture cannot be promoted as originally intended, so it is necessary to prevent the contamination of microorganisms from outside in advance.

Therefore, it is important to sterilize glassware, scalpels, tweezers, etc., that come in contact with the culture medium using dry heat sterilizers.

Principle of Dry Heat Sterilizers

Dry heat sterilization is a technique that uses heated dry air to thermally kill microorganisms attached to various instruments.

It can be used on glass, metal, and textiles with relatively high heat resistance.

A similar method is high-pressure steam sterilization using high-pressure saturated steam. However, dry heat sterilization can be used for instruments that should not be exposed to steam.

Typical sterilization conditions using dry heat sterilizers are 160°C for 90 minutes or 145°C for 45 minutes.

Dry heat sterilizers can be batch or continuous, depending on the heating method.

In the batch type, non-heated products are heat-treated in a single container, whereas in the continuous type, products to be heated are placed on a conveyor belt or similar device and heated in a furnace.

The batch method is less efficient because the product is removed after heat treatment, resulting in lower furnace temperatures. However, since multiple sterilizations can be performed under different conditions, this method is suitable for processing a large variety of products.

On the other hand, the continuous type is suitable for heat treatment of a large quantity of a small variety of products.