What Is an Axial Flow Fan?

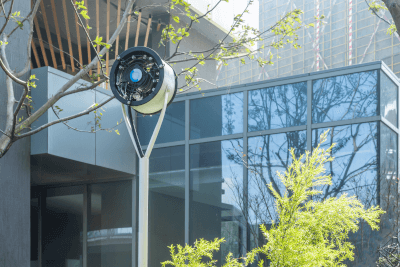

An axial flow fan is a type of fan that cools equipment. Air flows in from the front of the rotating blades (propeller) and out the back. Since the air flow is along the axis of rotation, it is called an axial flow fan. There are various types of fans, but the flow of air along the axis of rotation distinguishes axial fans from other fans.

Axial flow fan is available in both AC and DC power supply types, but a DC-powered axial flow fan can be easily controlled with a PWM signal when it is necessary to control the rotation speed.

Uses of Axial Flow Fans

Axial flow fans are used for cooling equipment. Specifically, they are used to cool the motors, driver circuits (circuit boards), microcontrollers, and other components installed in equipment to prevent malfunctions and damage due to heat.

They are used for purposes other than cooling in equipment that primarily handles paper, such as copiers and printers. By blowing air on a bundle of paper. Paper is removed one sheet at a time, or paper is sucked and transported by using the air-sucking power of a fan. It is also used for drying ink after printing.

Axial flow fans are also used in enclosed spaces to stir the air and exhaust air to prevent uneven temperature and humidity inside.

Principle of Axial Flow Fans

Axial flow fans have blades (propellers) placed in the center of the enclosure, and by rotating the blades, air is expelled from the front of the blades to the rear. Axial flow fans are low-noise and provide high airflow, but there are also a wide variety of products with enhanced features such as high airflow, high static pressure, and low noise.

Two axial flow fans can be connected in series or in parallel. When operating them in series, the airflow rate remains the same, but the static pressure can be increased. When they are operated in parallel, the static pressure remains the same, but the air volume can be increased.

When used for cooling, it is necessary to decide whether to use the airflow for discharge or suction, depending on the number and location of components that generate heat in the equipment. Dust in the air should also be considered. When used in a normal environment, dust in the air is also circulated during cooling, so dust will accumulate on the board over time, especially if the air is blowing directly onto the board. When this happens, consider installing a filter if necessary.