What Is an Electromagnetic Clutch?

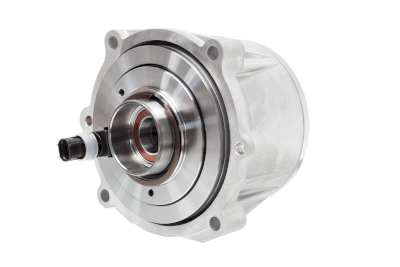

An electromagnetic clutch is a machine that uses electromagnetic force generated in a coil to connect two shafts and transmit power, or to disconnect two shafts and shut off power.

Since power transmission can be easily controlled by energizing the coil, not only can it be operated remotely, but it can also transmit power intermittently.

An electromagnetic clutch is classified into friction type, meshing type, pneumatic clutch type, and spring type, depending on the method of torque generation.

Of these, the friction type is the most commonly used because of its simple structure, low cost, and excellent controllability.

Uses of Electromagnetic Clutches

Electromagnetic clutches are used as machines that transmit the rotational power of engines, generators for automotive equipment, and driving power for hydraulic pumps.

Clutches can be mechanical, hydraulic, or electromagnetic, depending on their operating principle. However, electromagnetic clutches are commonly used in industrial applications. This is due to the fact that power transmission between shafts can be easily controlled by electromagnetic force.

In addition to automotive equipment, small electromagnetic clutches are used for torque transmission in office equipment and communication devices.

Principle of Electromagnetic Clutches

In addition to electromagnetic clutches, there are mechanical clutches and hydraulic clutches, depending on the actuation method.

Electromagnetic clutches are commonly used because they are easily controlled by electromagnetic force.

Electromagnetic clutches are classified into various types according to the torque generation method.

- Intermeshing clutch

A clutch engages the jaws of the driven shaft and the prime mover shaft to connect or disconnect the two shafts. Since engaging the claws during rotation generates a shock, the claws are joined during low-speed operation. - Friction clutch

A friction clutch transmits power by frictional force through contact between friction plates attached to the driving and driven shafts. Since the strength of the friction plates can be varied, smooth joints with minimal impact can be achieved even while the shaft is rotating. - Automatic clutch

Automatic clutches automatically transmit or shut off power when the rotation of a shaft exceeds certain conditions. As a result, power can be transmitted through the friction surfaces.