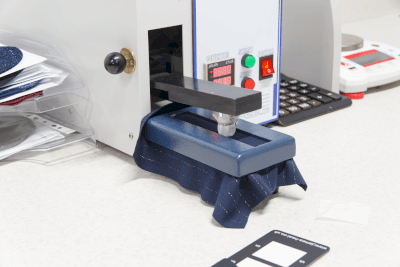

What Is an Abrasion Tester?

Abrasion testers are specialized machines used to evaluate the wear resistance of materials under various stresses such as tensile, compressive, and torsional. They’re crucial for testing materials like metals, plastics, and fabrics, simulating real-world conditions to measure properties like strength and hardness.

Uses of Abrasion Testers

These testers are instrumental in the development and quality assurance of products across industries, including industrial and construction equipment, medical devices, and automotive components. They help identify wear-related product failures and facilitate material selection, coating, and lubrication choices.

Principles of Abrasion Testers

Abrasion testers operate by applying a load to two contact surfaces under controlled conditions, including lubrication and temperature, to replicate wear processes. They measure wear amount and friction coefficients, providing insights into the wear mechanisms and material durability.

Features of Abrasion Testers

Designed to mimic the frictional wear surfaces experience, abrasion testers vary significantly to cater to the specific conditions under which materials are used. Despite the diversity in wear testing requirements, standardized methods are relatively few, reflecting the complexity of accurately reproducing wear phenomena.

Other Information on Abrasion Testers

Types of Friction Tests

Abrasion testers conduct various tests like Pin-On-Disk, Ball-On-Disk, Ring-On-Disk, Pin-On-Plate, and Ball-On-Plate, each assessing different wear characteristics such as friction coefficients and wear resistance under changing material conditions.