What Is a Refueling Pump?

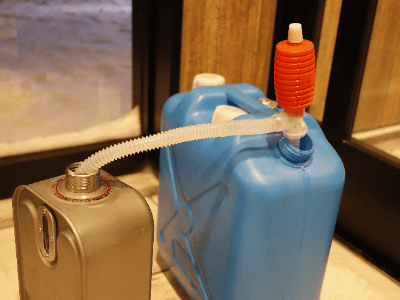

A refueling pump is designed to transfer fluids like kerosene, diesel, heavy oil, and crude oil from one container to another. Manually operated pumps don’t require electricity, making them usable during disasters, while electric pumps, which can be battery-operated or power-operated, offer faster pumping speeds. Electric pumps, however, may struggle with extracting the last bit of oil from a tank.

It’s important to consider the oil’s viscosity and choose a pump accordingly. Also, the length of the oil feed pipe varies, so selecting a convenient length for your needs is crucial.

Uses of Refueling Pumps

Refueling pumps are mainly used for transferring oils like kerosene and diesel oil. They are commonly used in households for refilling oil stoves. While some pumps can transfer water, they may not be suitable for potable water due to potential rusting, and many are not recommended for gasoline use unless specifically labeled for it.

Principle of Refueling Pumps

Refueling pumps come in electric and manual variants. Both types work by creating a difference in air pressure to transfer oil from the tank to another container. Electric pumps are effortless and typically feature an automatic shut-off function to prevent overfilling, available in both battery-powered and power-driven models.

Manual pumps include pressurized, hand-cranked, and bellows types. The pressurized type pumps oil by adding air pressure to a drum, the hand-cranked type works well for viscous oils, and the bellows type changes air pressure by compressing the bellows. Care must be taken with manual pumps to prevent overflow or backflow, especially if the oil feed pipe is lengthy.