What Are Flanged Shaft Couplings?

Flanged shaft couplings are mechanical devices designed to connect two rotating shafts for power transmission. They are made for permanent coupling needs, where shafts remain connected, and applications requiring disconnection capabilities similar to clutches.

These couplings are particularly valued for their ability to align the drive and driven shafts precisely, accommodating slight displacements, deflections, and ensuring high rigidity and accuracy in power transmission and shaft alignment.

Uses of Flanged Shaft Couplings

Flanged shaft couplings perform essential roles in various applications:

- Power Transmission: They efficiently transfer power from the drive side to the driven side.

- Error Absorption: They compensate for shaft mounting errors, ensuring smooth operation.

- Vibration Absorption: They mitigate vibrations, protecting machinery and reducing environmental noise.

By fulfilling these roles, flanged shaft couplings enhance the operation of machinery with rotating parts, reducing vibration effects and ensuring stable performance.

Principle of Flanged Shaft Couplings

Shaft couplings are classified into various types:

- Fixed shaft couplings for linear connections.

- Deflection shaft couplings for straight alignments with flexibility.

- Flexible shaft couplings for crossed shaft arrangements.

- Other types designed for parallel shaft connections.

Flanged shaft couplings connect driving and driven shafts in a straight line using flanges and coupling bolts. This setup allows for minor misalignments, transmitting motor rotation or movement from other equipment with high fidelity.

2. Features of Deflection Shaft Couplings

Deflection shaft couplings, including gear and roller chain types, offer specific benefits:

- Reduced torsional deformation and high torque transmission, ideal for high-speed applications without shock or vibration absorption.

- Compact sizes and ease of assembly/disassembly, with some requiring lubrication for optimal performance.

Elastic shaft couplings, like metal spring types, provide backlash-free operation and longevity without internal friction damping.

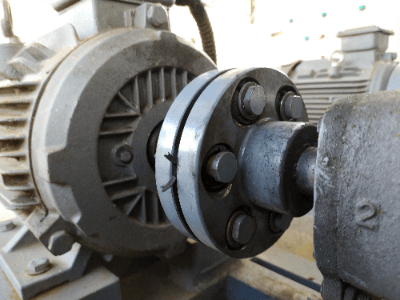

Structure of Flanged Shaft Couplings

Comprising two flanges connected by bolts, flanged shaft couplings use elastic rubber bushes to fasten the flanges together, allowing for angular misalignment tolerance. The design ensures torque transmission through bushing compression while accommodating shaft flexibility.

Other Information on Flanged Shaft Couplings

1. Material

Materials for flanged shaft couplings must comply with industry standards to ensure durability and proper function. Components include flanges, joint bolts, nuts, washers, spring washers, and bushes, each selected for quality and performance.

2. Maintenance

Regular maintenance, including bushing inspection and replacement, is crucial for prolonging the lifespan of flanged shaft couplings. Attention to bushing material is important, as some materials degrade faster when exposed to certain chemicals or oils.