What Is a Plastic Screw?

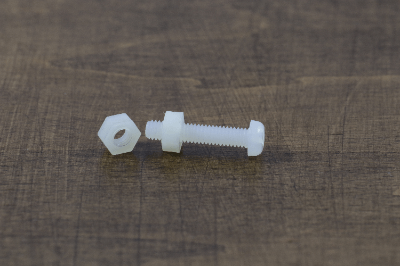

A plastic screw is a screw made from resin (plastic) instead of metal.

Compared to metal screws, plastic screws are lighter in weight and have superior insulation, corrosion resistance, and thermal insulation properties. Polycarbonate (PC) is the most common material used for plastic screws, while PEEK and RENY are also used. The characteristics of the screw also vary depending on the material used.

Plastic screws are manufactured in a variety of shapes and sizes, such as small screws, hexagonal bolts, potato screws, and knurled screws, to suit various locations and applications. Dimensions are made according to JIS and ISO standards, as with metal screws. However, due to the difference in manufacturing methods from metal screws, some dimensions may not conform to JIS or ISO standards.

Uses of Plastic Screws

Plastic screws are used in a variety of industries, with applications varying depending on the type of resin used. For example, PC is used in electrical and electronics to medical fields for its high impact resistance and balanced mechanical and electrical properties. PEEK is suitable for office automation equipment, automobiles, IC wafer carriers, and LCD manufacturing jigs due to its excellent chemical, heat resistance, and abrasion resistance. RENY is used as a substitute for metals in automobiles, general machinery, and other applications because of its extremely high strength and modulus of elasticity, as well as excellent oil and heat resistance. PPS is used in automotive and mechanical parts for its high heat resistance, and PP is widely used for plastic screws in everyday items due to its low specific gravity and versatility.

Principles of Plastic Screws

Even though they are made of plastic, the fastening principle of a plastic screw is the same as that of a regular screw. By using the spiral slope of a screw, a large axial force (fastening force) can be generated even with a relatively small tightening torque. However, compared to metal, the elasticity of resin is much smaller, resulting in a lower fastening force. Therefore, plastic screws are best utilized in applications where their unique characteristics, rather than strength, are needed.

Manufacturing Method of Plastic Screws

Plastic screws are typically manufactured by injection molding. This process involves melting resin and pouring it into a mold, which is then cooled to form the screw. In some cases, screws are manufactured by cutting or press working. Press working involves softening plastic sheets by heating and pressing them between sheets in a mold attached to a press machine.

Characteristics of Plastic Screws

Plastic screws have many excellent features, such as lower specific gravity compared to metal screws, high electrical resistance, excellent insulation properties, corrosion resistance, low thermal conductivity, no magnetism, unique plastic appearance, and recyclability.