What Is a Vertical Conveyor?

A vertical conveyor is a specialized conveying equipment designed to move objects or luggage vertically to different levels.

Distinct from elevators, vertical conveyors are specifically engineered for transporting goods in a vertical direction and are not meant for transporting people.

Compared to traditional cargo elevators, vertical conveyors typically offer higher transport capacity. They are not categorized as “elevators” under building regulations, thus simplifying installation by eliminating the need for building certification or permits from labor regulatory bodies.

Uses of Vertical Conveyors

Vertical conveyors are commonly used in factories, distribution centers, and warehouses to efficiently transport large loads. They are especially effective for moving carts and pallets simultaneously, handling substantial quantities of goods.

While elevators can also be used for vertical transportation of goods, vertical conveyors are often more cost-effective, approximately half the cost of installing an elevator when considering installation and procedural aspects.

Principles of Vertical Conveyors

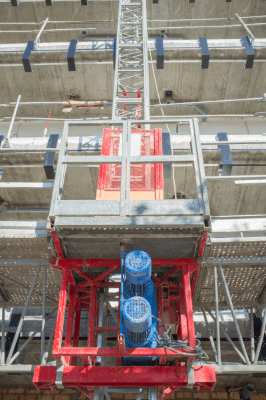

While similar in function to an elevator, the structure of a vertical conveyor is more akin to a “shelf,” making it relatively simple. The main body frame houses a carriage (cage or platform) and weights, with the carriage being raised and lowered by a suspension chain or metal wire driven by a motor unit.

There are also conveyor-type vertical conveyors where the entrance is integrated with a conveyor belt. These types are particularly efficient and safe for continuous vertical movement of loads, such as in manufacturing plant lines.

While vertical conveyors offer cost advantages over elevators, it is important to note that the size and weight of the items to be conveyed are subject to strict guidelines set by the type of conveyor and the manufacturer, limiting what can be transported.