What Is a Three-Phase Motor?

Three-Phase Motor is an electric motor driven by a three-phase AC power source.

They are widely used as power sources for industrial equipment and machinery. Also called three-phase induction motors (induction motors), they are generally powered by a three-phase AC power supply of 200 VAC.

Three-Phase Motors consist of a stator, rotor, output shaft, flange bracket, and ball bearings.

Usage of Three-Phase Motor

AC power supplies are classified as single-phase and three-phase. Single-phase is an AC power source mainly used in general households. On the other hand, three-phase motors are mainly used in the industrial field.

Specific applications of Three-Phase Motors are as follows

- Compressors

- Pumps

- Fans

- Belt conveyors

- Cranes

- Motors for EVs

Three-Phase Motors have a wide range of applications and are used in many industrial machines other than those listed above.

Among Three-Phase Motors, there are also stepping motors and servo motors, which are used to precisely control rotation. These are used in the use of automated machinery such as industrial articulated robots.

Principle of Three-Phase Motor

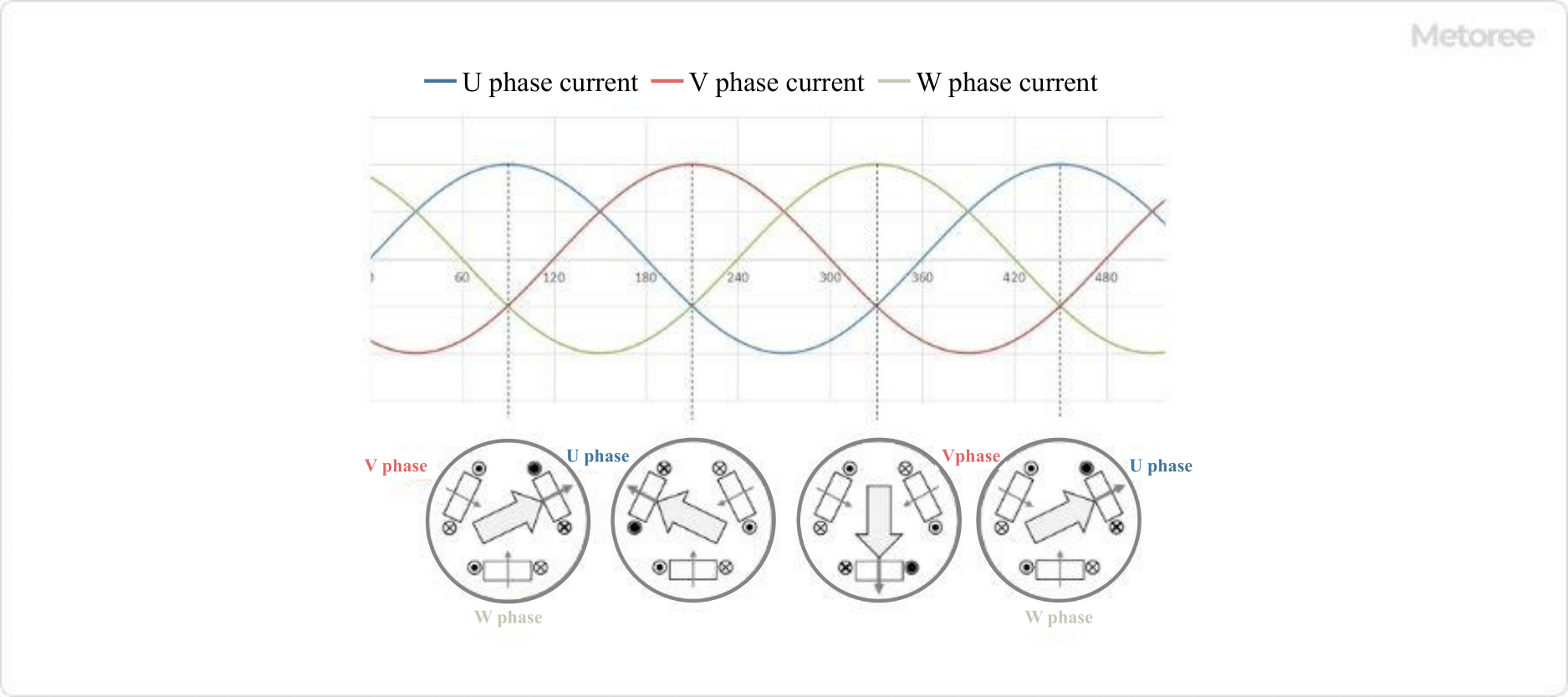

In Three-Phase Motors, three-phase AC power with a phase shift of 120 degrees is applied to the coils of a stator, and the coil to an electromagnetic steel plate becomes an electromagnet, forming a magnetic field inside the motor. The polarity of the electromagnet is determined by the direction of the current flowing through the coil and the right-hand thread law.

Since the AC power source is out of phase with time, the direction of the magnetic field rotates with time.

Figure 1 shows the principle of generating a rotating magnetic field. As the phases of the U, V, and W phases of the three-phase AC power supply change, the direction of the stator’s magnetic field changes (in Figure 1, the rotating magnetic field rotates counterclockwise).

Figure 1. The principle of rotating magnetic field generation

The rotation of the magnetic field generates eddy currents to the rotor, and the eddy currents and the magnetic field generate a force on the rotor. As a result, power is generated on the motor’s rotating shaft. The direction of the rotational force of the motor is determined by Fleming’s left-hand rule.

The speed of the rotating magnetic field as the rotor rotates is called the synchronous rotation speed. The synchronous rotation speed can be calculated from the frequency of the power supply and the number of stator poles.

The actual rotational speed of the rotor is slightly slower than the synchronous rotational speed. This is because the magnetic flux crossing the rotor conductors generates an induced current that causes the rotor to rotate.

The difference between the synchronous rotation speed and the actual rotation speed is called “slip.” The greater the load torque, the greater the slip. The output (W) of a motor can be calculated from its rated rotational speed and rated torque.

Other Information on Three-Phase Motors

1. Wiring for Three-Phase Motors

Three-Phase Motors are wired differently depending on the starting method. Four types of starting methods are introduced here.

Direct-in Starting

Three-Phase Motors are started by applying three-phase AC power directly to their terminals via an electromagnetic contactor. Wiring is easy, but the current flowing through the motor during starting (starting current) is large, several times the rated current.

This method is often used with small capacity motors that require a low starting current.

Star-Delta Starting

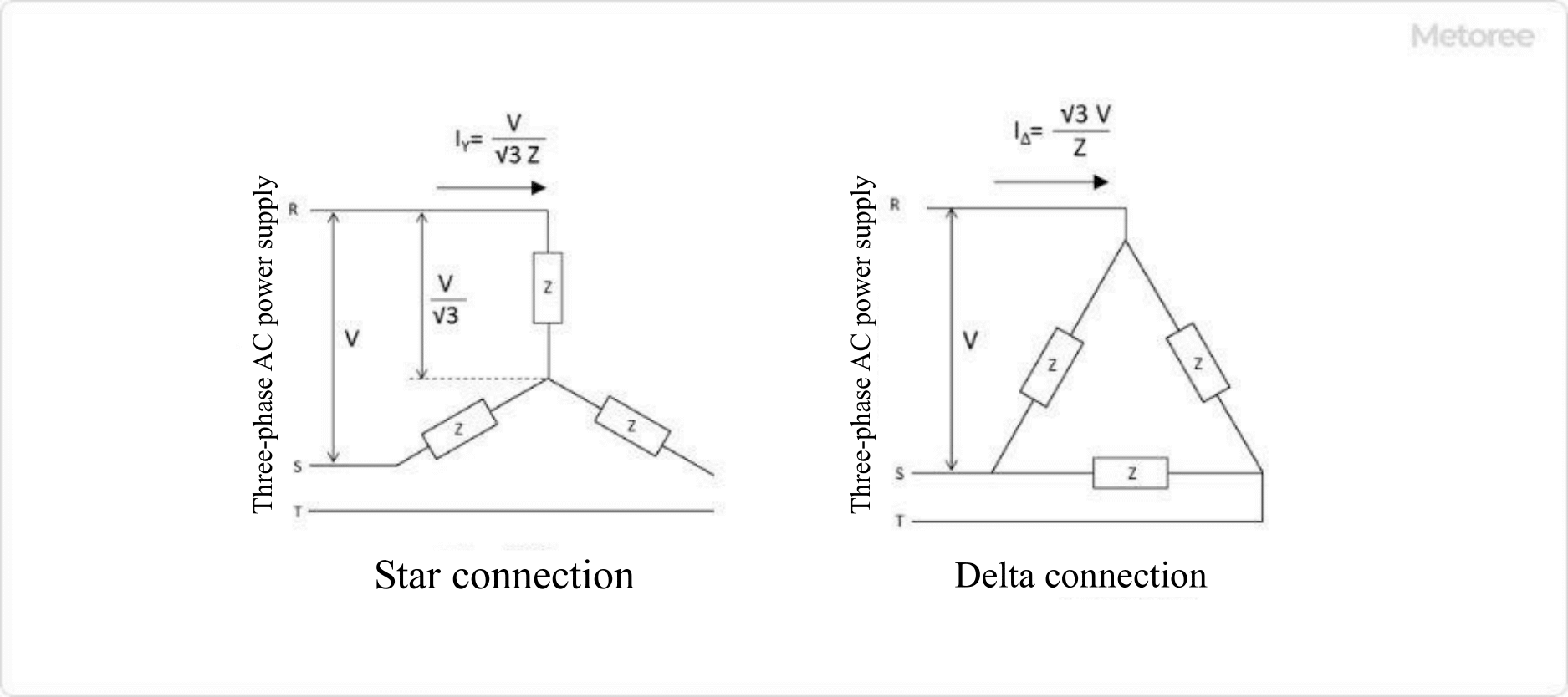

This is a starting method that starts with star wiring and then switches to delta wiring.

There are two types of motor wiring: star-wired and delta-wired (Figure 2). Star-wiring requires only 1/3 of the starting current of delta-wiring, so it is the starting method used for Three-Phase Motors with a high rated current.

Figure 2. Star and delta connections

The terminal box of a star-delta starting motor has six terminals (U, V, W, X, Y, and Z). Outside the stator windings is a circuit that combines an electromagnetic contactor and a timer to automatically switch between star and delta wiring.

Reactor Starting

A reactor is connected between the Three-Phase Motor and the power supply at startup, and the circuit of the reactor is disconnected with an electromagnetic contactor and timer a short time after startup.

Inverter Starting

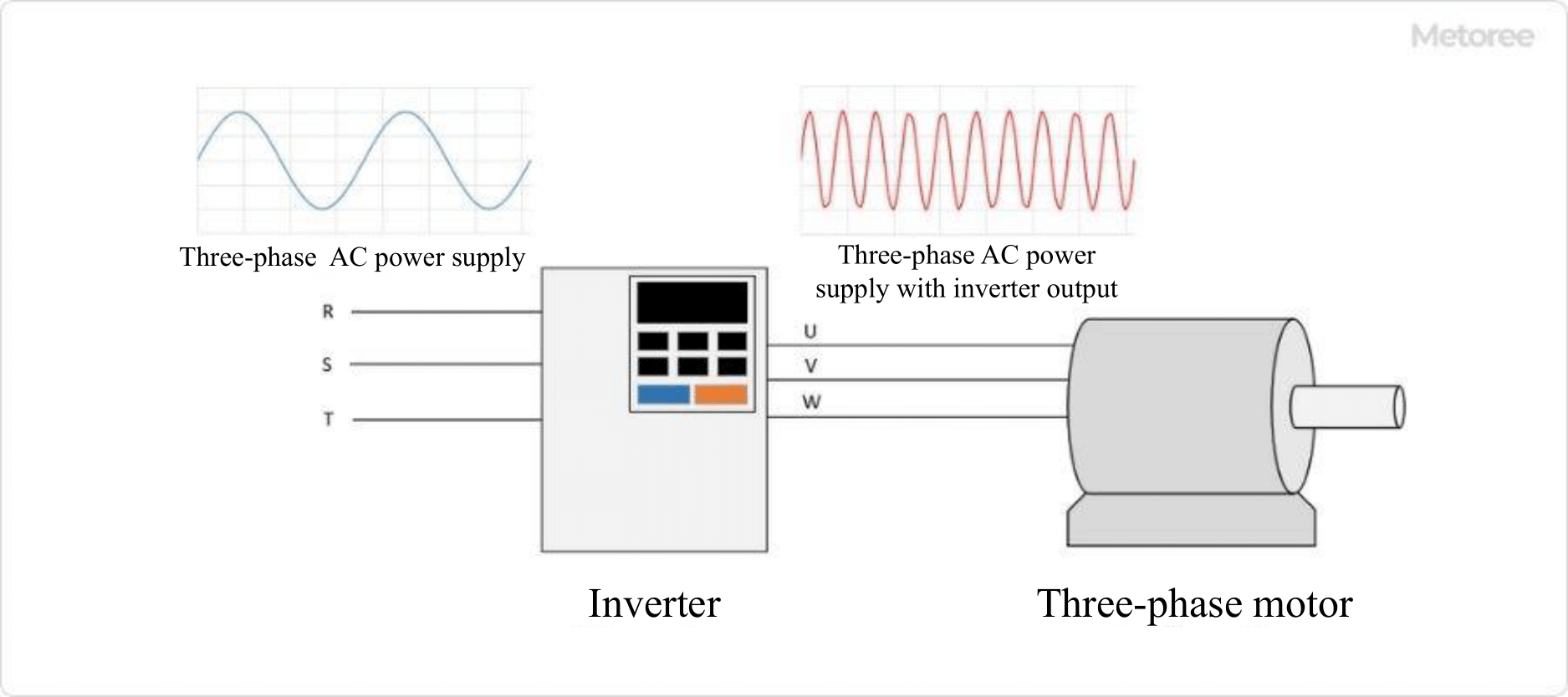

An inverter is an electrical device that controls the speed of a Three-Phase Motor (Figure 3). It can freely change the output and frequency of the three-phase AC power supply.

By installing an inverter, the motor can be started from a low frequency of a few Hz and the starting current can be reduced.

Figure 3. Three-phase motor and inverter

2. Rotational Speed of Three-Phase Motor

The formula for the number of revolutions is 120 x the frequency of the AC power source/number of poles.

For example, for a 4-pole motor with a 50 Hz power supply, the number of revolutions is 120 x 50 ÷ 4 = 1500 rpm.

However, Three-Phase Motors rotate with a slight lag behind the power supply frequency. This delay is expressed as the slip ratio. If the slip ratio is 5%, the speed will be 1500 x (1-0.05) = 1425 rpm.

To control the speed of a Three-Phase Motor, either the frequency or the number of poles must be controlled, but the number of poles cannot be changed because of the structure of the motor. Therefore, the frequency must be changed to control the speed. Currently, inverters are the most common way to control the speed of Three-Phase Motors.