What Is a Hammermill?

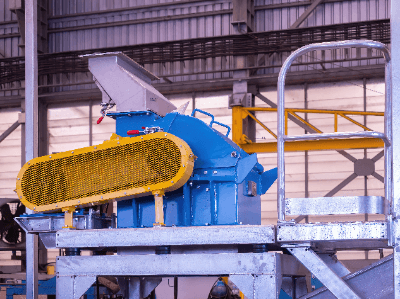

A Hammermill is a device that can instantaneously grind various raw materials by feeding them through a hopper and rotating a hammer installed on the rotor at high speed, thereby impacting the fed materials.

A Hammermill is a device that can instantaneously grind various raw materials by feeding them through a hopper and rotating a hammer installed on the rotor at high speed, thereby impacting the fed materials.

The hammer part can be a movable or fixed type, and the rotation speed can be changed to change the particle size of the material. The screen part is attached to the outlet after processing and used as a filter, and by changing the mesh of the screen, the particle size can be uniformly adjusted.

Therefore, by changing the combination of hammers and screens, the mill can be used for a wide variety of applications.

Uses of Hammermills

Hammermills are used for fine grinding, i.e., to grind particles of a few centimeters to a size of 10 to 1 micron. Hammermills are used for a wide variety of applications, ranging from the processing of building materials to food and pharmaceuticals.

There are different types of hammermills, depending on their purpose and use. Hammermills with fixed hammers are used for grinding and processing raw materials, and are suitable for soft materials such as grains, or when the required load is small and the rotation of the hammer is low.

Hammermills with movable hammers are suitable for hard materials such as ores and wood, or when a large impact is required for crushing.

Principle of Hammermill

Hammermills grind by rotating the hammer at high speed and swinging the hammer to impact the object to be processed. Therefore, the impact can be adjusted according to the material and application of the object by the rotation speed of the hammer and the swinging motion.

A screen is installed at the outlet of the crushed workpiece to adjust the particle size after processing to ensure consistent quality. Although the machine is noisier and vibrates more, it is characterized by its high crushing capacity and ability to process relatively hard materials.

In addition, its simple structure makes it easy to disassemble, reassemble, replace parts, and perform other maintenance. In addition, the use of super steel makes it possible to take countermeasures against wear, so it has a long service life and can be used for a long period of time.

Cautions for Hammermills

Hammermills have a simple structure and can be used to grind various types of materials, but there are some points to note. Hammermills are suitable for hard, brittle, and easily broken materials because the impact force of the hammer crushes the sample. On the other hand, elastic or fibrous materials such as plastics cannot be crushed very finely.

In addition, for not only hammermills, but also other dry mills, it is difficult to grind materials with water or oil content, such as food, because they stick to the equipment or clog the screen. In addition, hammermills can heat up when operated for long periods of time, so care must be taken when grinding heat-sensitive samples.

Thus, it is important to select the appropriate milling machine depending on the sample to be milled, since the appropriate milling mechanism varies depending on the material characteristics.