What Is a Thermal Conductivity Analyzer?

A thermal conductivity analyzer is a device used to measure the thermal conductivity of a material.

There are various types, such as those that use a heat plate, hot wire, or laser. Thermal conductivity is the value of the ease of heat transfer within a material and is one of the points that characterize a material. For example, pots and pans can be heated faster if the thermal conductivity is high and retains heat better if the thermal conductivity is low.

Uses of Thermal Conductivity Analyzers

Thermal conductivity analyzers are used to evaluate product manufacturing methods and to develop new materials and products.

1. Evaluation of Heat Retention Performance

For example, the thermal insulation performance of a storage container is evaluated. The lower the thermal conductivity, the higher the thermal insulation and the longer it can keep warm. We measure thermal conductivity as an indicator of this performance.

2. Development of Heat-Dissipating Materials

Recently, thermal conductivity has been increasingly used in the development of heat-dissipating materials, as heat dissipation is an important factor in CPUs and other devices to prevent thermal runaway caused by heat generation.

For example, the higher the thermal conductivity of the thermal conductive grease used to improve heat dissipation, the higher the heat dissipation.

Principle of Thermal Conductivity Analyzers

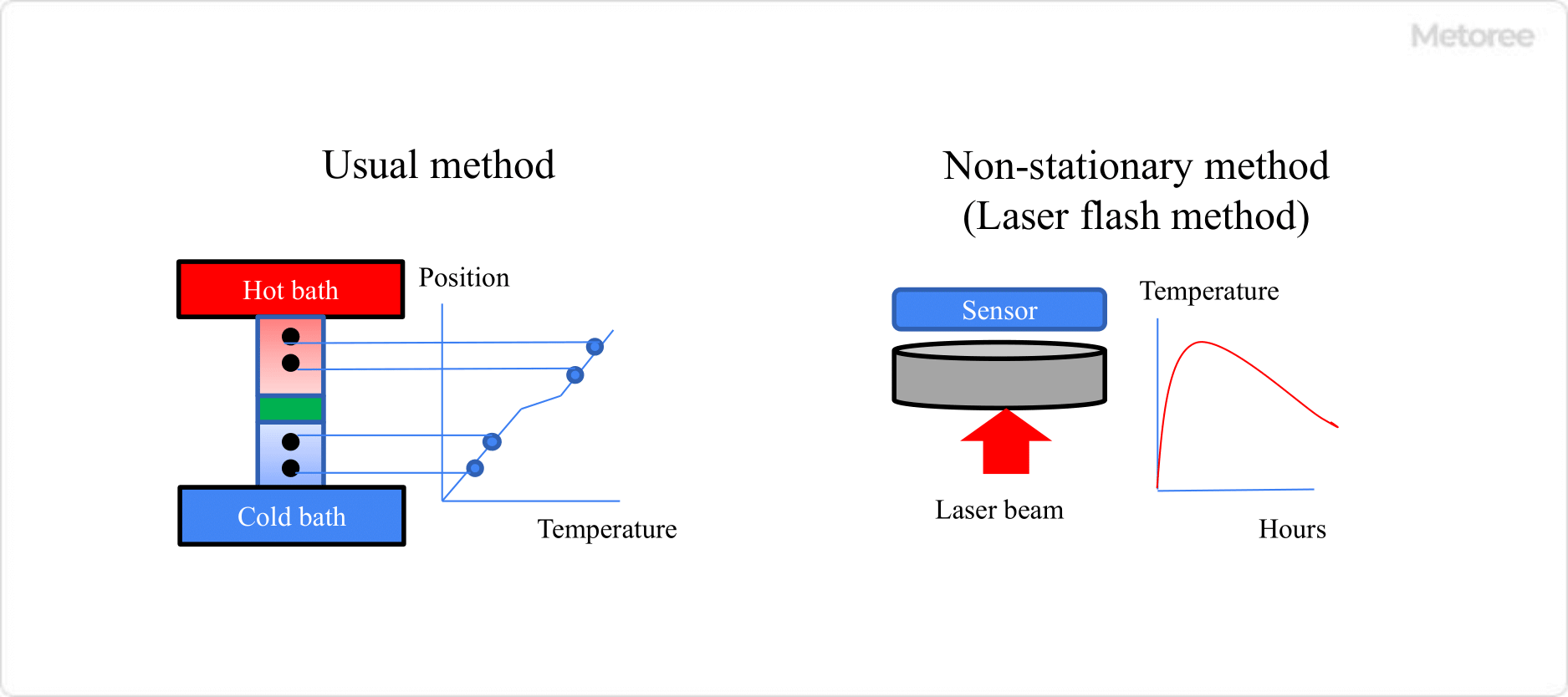

Figure 1. Steady-state and non-steady-state methods

Thermal Conductivity Analyzers can be broadly classified into the Steady-State Method and the Non-Steady-State Method.

1. Steady-State Method

The steady-state method directly measures thermal conductivity by generating a steady thermal gradient. A steady heat flow is generated by making one side of the sample hot and the other side cold.

By measuring the heat flux from a heat flux meter or a material of known thermal conductivity and temperature, the thermal conductivity can be measured from the temperature difference generated in the sample. The simple principle makes accurate measurements possible, but temperature control of the sample surface and heat dissipation to the surroundings can cause errors. Another disadvantage is that it takes a lot of time to reach a steady state.

2. Transient Method

The transient method is a method to measure thermal conductivity by applying non-steady heat to a sample. By measuring the change in sample temperature over time after heat is applied, the thermal conductivity can be calculated. There are two methods of applying heat: the laser flash method using a laser beam and the hot wire method using a heater wire, etc. The laser flash method uses a laser beam to apply heat to the sample.

In the laser flash method, the sample is heated using a laser beam and is detected by an infrared sensor. The disadvantage of this method is that it is difficult to detect samples with too small a thermal conductivity. In the hot wire method, the sample is heated by passing a hot wire inside the sample. This method can be used to measure without distinction between solids and liquids.

Other Information on Thermal Conductivity Analyzer

1. Difference From Thermal Diffusivity Measurement Device

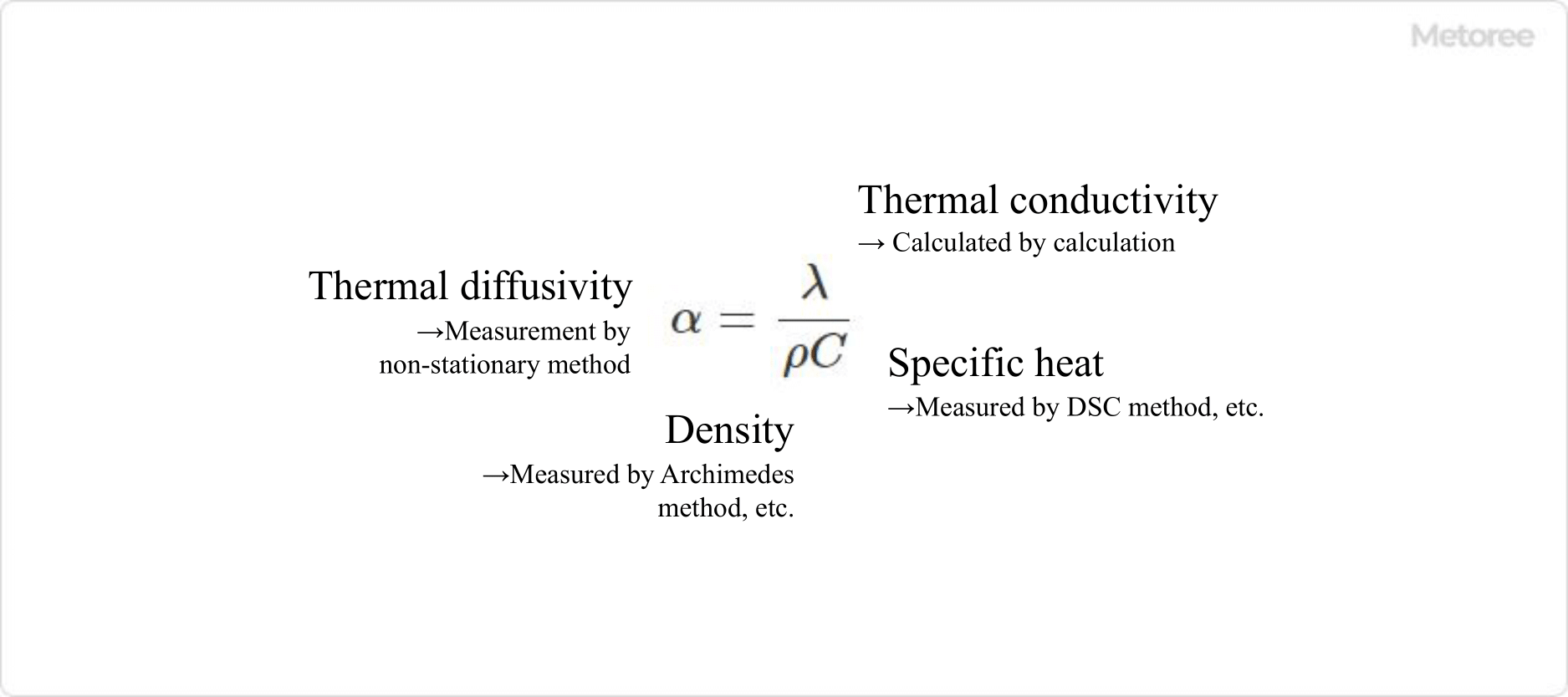

Figure 2. Thermal diffusivity and thermal conductivity

Thermal diffusivity is generally measured by devices using the laser flash method, but thermal conductivity cannot be measured directly. Thermal conductivity can be obtained by multiplying the thermal diffusivity obtained with a laser flash measurement device by the specific heat and density.

The specific heat is measured by a differential thermal analyzer (DSC), and the density is measured by a method such as the displacement method known as Archimedes’ method in water. The laser flash method can be used to measure the thermal diffusivity of a wide range of materials, including rubber, plastics, and other polymers, ceramics, and even metals. On the other hand, there are restrictions on test conditions, and the materials to be measured are dense rather than porous.

The material must be free of defects, such as shrinkage porosity and cracking, which are common in metallic materials. Therefore, composite or laminated materials made of fibers or granular materials cannot be measured.

In addition to the laser flash method, the thermal diffusivity measurement system also includes a cyclic heating method. In this method, the temperature response or phase difference is determined from the temperature response or phase difference at a certain distance away when periodically varying thermal energy is applied. However, this method also cannot directly measure thermal conductivity.

2. Rapid Thermal Conductivity Meter (Non-stationary Fine Wire Heating Method)

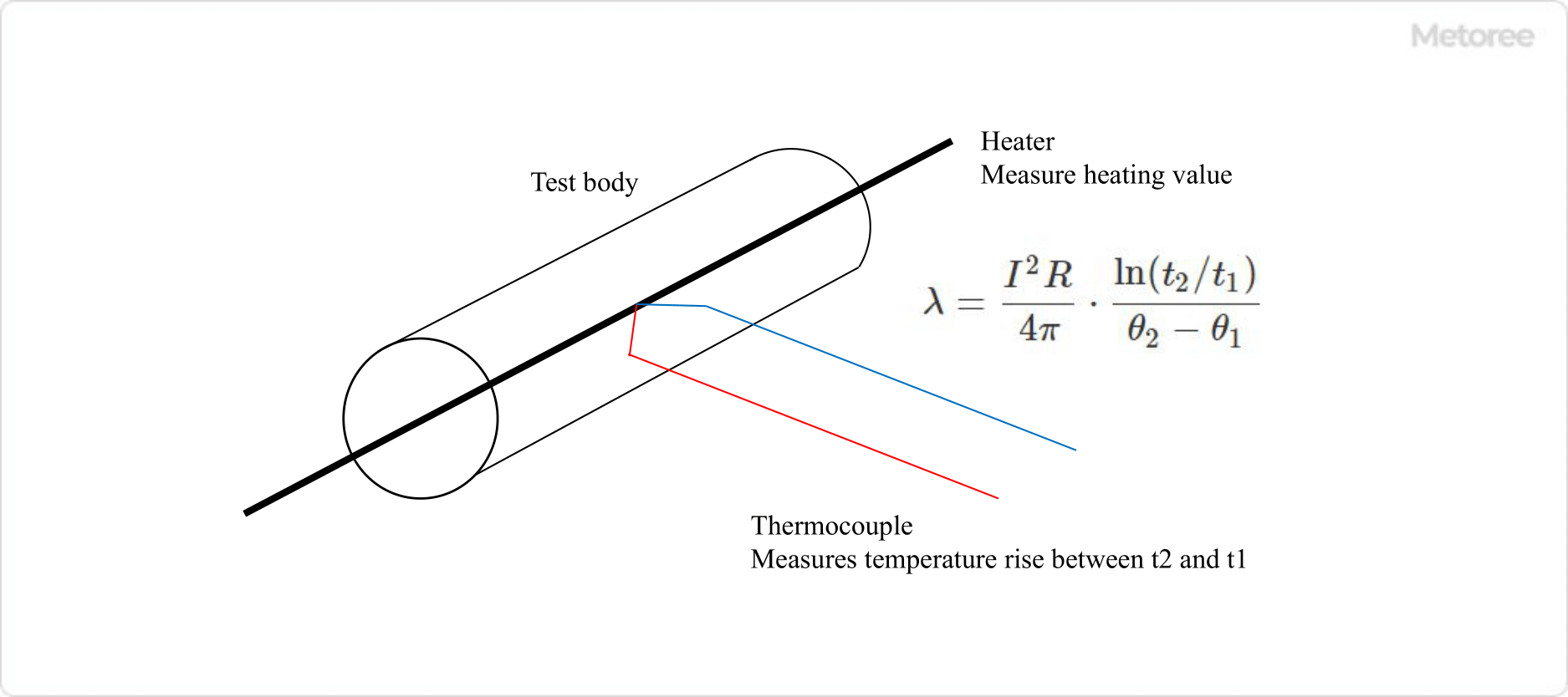

Figure 3. Non-steady-state fine wire heating method

For rapid measurement of the heat transfer coefficient, a rapid heat transfer coefficient meter using the unsteady thin-wire heating method is effective. The sensor part consists of a heating wire stretched in a straight line and a thermocouple, and a constant current is applied to raise the heating temperature.

For example, if the specimen has high thermal conductivity, such as ceramics, heat diffuses rapidly into the specimen and the temperature of the heating wire decreases. Conversely, for a specimen with low thermal conductivity, the temperature of the heating wire rises, and the thermal conductivity can be determined from the slope of the temperature rise graph at this time.

Thermal Conductivity Analyzer can quickly and easily measure the thermal conductivity of a uniform specimen, and the analyzer itself is small enough to be carried around. The measuring instrument itself is compact and portable, making it possible to take measurements immediately on site, another major advantage. It can be used for a wide range of applications, from industrial building materials to food and clothing.

Examples of test specimens that can be measured are as follows:

- Fiber-based and foamed plastic insulation materials, etc.

- Plastics, glass, wood, etc.

- Sheets, skins, thin plate samples, etc.

- Bread dough, paste, powder, etc.

- Refractory insulation materials at high temperatures, ceramics, etc.