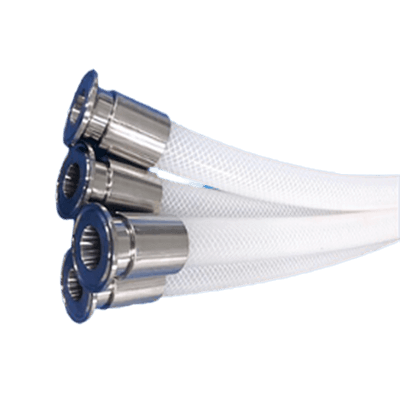

What Is a Braided Hose?

Braided hoses incorporate reinforcement to enhance flexibility and pressure resistance. Commonly crafted from vinyl chloride with polyester yarn or Tetoron reinforcement, these hoses excel in strength while maintaining flexibility. Some variants feature a stainless steel wire exterior for additional protection. These hoses are notable for their durability, resistance to environmental changes, and cost-effectiveness, requiring minimal maintenance.

Uses of Braided Hoses

Braided hoses serve various applications across industries, leveraging their pressure and heat resistance. They are indispensable in construction and manufacturing for fluid supply, including chemicals and raw materials. Their flexibility and durability make them ideal for drainage operations and agricultural irrigation, ensuring efficient water and fertilizer delivery.

Principle of Braided Hoses

The core of a braided hose, designed for fluid transport, is typically made from rubber, plastic, or synthetic materials, surrounded by a protective braid of metal helical strips or synthetic fibers. This structure enhances the hose’s flexibility, durability, and tensile strength, allowing it to withstand internal fluid pressure. Connection components at both ends ensure stable and sealed connections to other equipment.

Types of Braided Hoses

There are primarily two types of braided hoses:

- Polyester-Based: Features a vinyl chloride body reinforced with polyester yarn, offering electrical insulation and a lighter weight, though less heat resistance.

- Stainless Steel: Encases the resin body with stainless steel wire, providing superior high-pressure and temperature resistance but at a higher cost and weight.