What Is a Drill Chuck?

A drill chuck is a chuck used to secure rotating tools such as drills and screwdrivers. It is used in machine tools such as electric drills and lathes to secure the tool to the machine.

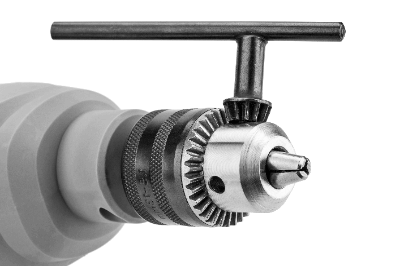

There are two types of drill chucks: keyed drill chucks and keyless drill chucks. In the case of keyed drill chucks, the cutting tool is chucked by connecting and turning a handle called a chuck key. In the case of keyless drill chucks, the cutting tool is chucked by turning a rotating sleeve on the drill chuck.

Uses of Drill Chucks

Drill chucks are used to hold tools such as drills and screwdrivers and are installed in the rotating parts of small machines like electric drills and screwdrivers, as well as relatively large processing machines such as lathes and milling machines.

Since these machine tools use different tools depending on the hole diameter and screw size for each machining procedure, it is necessary to change tools. Drill chucks improve workability by making it easy to attach, detach, and replace tools.

Principles of Drill Chucks

Drill chucks mainly consist of a jaw to hold the tool in place, a jaw guide designed to narrow the distance between the jaws as they are pushed out, and a feed screw to push the jaws out. Three jaws are arranged at 120° intervals around the circumference, and the tool is held in place at three points, ensuring that the center of the axis always coincides.

When the holder of the drill chuck is rotated manually, the jaws are pushed out by the feed screw, narrowing the width of the jaws and securing the tool. Depending on the product, the distance between the jaws generally widens from about 1 mm to 6 mm or more, allowing tools of various outside diameters to be secured.

On the other hand, since the contact area with the tool’s outer diameter is limited to the tips of the three jaws, the tool surface may be deformed depending on the tool’s strength. For precision machining of a few micrometers or accurate positioning with a slice bar, a collet chuck is used, which can clamp the tool almost around its entire outer circumference. However, when using a collet chuck, it is necessary to prepare a chuck for each tool’s outer diameter.