What Is a Roll Coater?

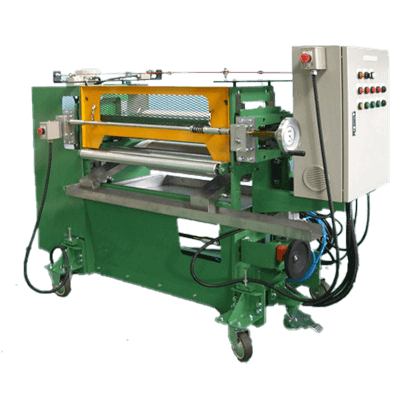

A roll coater is a machine that uses rollers to apply a coating to a flat surface, such as film.

Roll coaters apply paint, adhesives, chemicals, and other materials evenly. They are also equipped with a sputter source and plasma CVD, enabling continuous and high-speed deposition of barrier films, transparent conductive films, etc. Generally, it is limited to coating thin flat surfaces, such as sheets and films.

The applications are diverse depending on the combination of technologies, and various coating thicknesses and viscosities can be used. Therefore, the fields of application for roll coaters range from optics, liquid crystal products, and electronic components to chemicals and foodstuffs.

Uses of Roll Coaters

Roll coaters are used for functional films in optical products for tablets, smartphones, and other high-performance, low-profile devices, as well as for high-density, compact components. Film types include light control, anti-reflection, anti-glare, polarization, light diffusion, screen protection, and transparent conductivity.

They are also used in films for solar cells and secondary batteries. Types of films include reflector, light shielding, decorative, and heat dissipation. Thin film coating technology is used in automobiles, textiles, housing, electronic components, and semiconductors.

Principle of Roll Coaters

Roll coaters use multiple rollers to apply paints, adhesives, chemicals, conductive films, barrier films, and optical films to films and other materials. Rolls have various names such as “coater roll,” “doctor roll,” “feed roll,” “knife roll,” “guide roll,” and “gravure roll.”

Linear bearings are used to raise and lower the upper roller section to maintain high accuracy and smooth operation for a long time. The opening height can be adjusted. The rolls can be removed and reassembled in a short period for easy replacement.

The doctor roll open/close handles are integrated on both sides, enabling accurate and quick adjustment of application volume. Each roll is independently driven and can be divided into types according to the deposition process. The system is classified according to whether the coating amount is measured and selected and whether the coating liquid is before or after coating, and a combination of multiple systems can be used.

Types of Roll Coaters

Various types of roll coaters are in practical use. The two main types are the direct roll coater and reverse roll coater. They can also be classified according to whether the coating liquid is released or sealed.

1. Direct Roll Coater

The direction of rotation of the rolls and the direction of the object to be coated are the same. Also called natural roll coater. The material to be coated is fed between the rubber-lined coating roll and the steel backup roll.

2. Reverse Roll Coater

In this method, the coated object will travel in the opposite direction of the roll rotation. The coating rolls rotate in the opposite direction and roll over the coated object sent by the roller called the backup roll.

Compared to the direct roll, the reverse roll can apply a thicker coating at a time and has a cleaner surface, so it is widely used for primer coating, etc.

3. Post Metering Roll Coater

The post-metering coating method is a method in which extra coating liquid is applied once and then scraped off to the desired amount. It is called a knife coater or roll coater with blades, etc. The amount of scraping off and film thickness are determined by setting the shape and gap of the rolls.

Other Information on Roll Coaters

1. Roll Coaters for Special Purpose

Sputter Roll Coater

Sputter roll coaters use the sputtering method to deposit metal, transparent conductive, and optical films used in solar cells, touch panels, window films, and FPDs.

Plasma CVD Roll Coater

A plasma CVD roll coater uses electrical discharges generated between rollers to deposit silica films to achieve barrier properties used in organic EL, e-paper, lighting, solar cells, etc.

AIP Roll Coater

An AIP roll coater deposits metallic compound films by evaporating target materials using vacuum arc discharge.

2. Development and Trends of Roll Coaters

The problem with roll coaters is that the equipment is large due to the large area of the target material, and the setup and changeover are extensive. In recent years, roller cassettes have been introduced for coaters that can easily accommodate changes in coating conditions.

Coater equipment has become more sophisticated and complex, and it is desirable to have coaters that can measure, monitor, and record the condition of the coating surface, equipment, and workpiece using laser displacement gauges, cameras, and sensors.