What Is a Leak Detector?

A leak detector is a device or system for detecting leaks or spills. Its primary purpose is to identify leaks of gases, liquids, or other fluids at an early stage to prevent accidents and losses.

Leak detectors are widely used to enhance safety and efficiency, playing a crucial role in monitoring industrial processes and infrastructure.

Uses of Leak Detectors

Leak detectors find applications across various industrial fields. Here are some examples of their applications:

1. Gas Leak Detection

Leak detectors are employed to identify leaks of combustible gases such as natural gas, propane, and methane. Gas leaks can lead to fires and explosions, making early detection critical for ensuring safety. They are used in gas supply systems, petrochemical plants, and gas pipelines, among others.

2. Liquid Leak Detection

These detectors are used to identify liquid leaks, including water, oil, and chemicals. They help minimize the damage caused by leaks, which can result in environmental pollution and material wastage. Liquid leak detectors are applied in water pipes, oil pipelines, tanks, and storage facilities.

3. Underground Pipe Leak Detection

Leak detectors are utilized to locate leaks in underground water pipes and piping systems. Groundwater leaks can lead to land subsidence and a decline in the groundwater table, resulting in the wastage of water resources and environmental issues. These detectors are used by local governments and water utilities.

4. Vacuum System Leak Detection

Leak detectors are used to identify leaks in vacuum systems and sealed containers. Vacuum leaks can negatively impact the accuracy of manufacturing processes and experiments. They find applications in the semiconductor industry, medical equipment, and the space industry.

Principle of Leak Detectors

Leak detectors function by detecting changes in pressure, sound waves, and flow rate when a leak occurs. For instance, vacuum leak detectors detect pressure fluctuations. When a leak happens in a sealed vacuum vessel, the pressure rises rapidly, and the vacuum leak detector identifies this fluctuation.

In the case of groundwater leaks, sound changes are detected. Sound waves generated by the flow of water at the leak site are detected, enabling precise leak location.

Flow meters can also be used to detect leaks. When a leak occurs, the flow rate may be lower than expected, prompting detection and alerting of a leak.

Types of Leak Detectors

Several types of leak detectors are available. Here are some examples:

1. Gas Leak Detector

Gas leak detectors identify gas leaks using ultrasonic sensors or gas concentration sensors. Ultrasonic sensors emit high-frequency sound waves (ultrasonic waves) and detect changes in the time and intensity of the reflected sound waves from objects. This principle is employed to detect leaks and leak points. Gas concentration sensors measure the concentration of combustible gases, such as methane gas, to detect increases indicative of gas leaks.

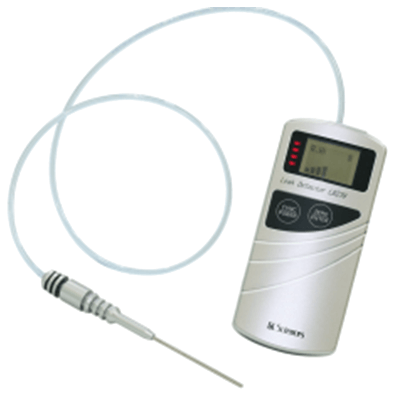

2. Liquid Leak Detector

Liquid leak detectors use flowmeters or capacitance sensors. Flowmeters measure liquid flow and detect deviations from expected flow rates when a leak occurs. They are used in chemical solution transfer piping, including sulfuric acid handling. Capacitance sensors employ electrodes to detect liquid presence; changes in capacitance occur when a liquid or powder comes into contact with the sensor.

3. Vacuum Leak Detector

A vacuum leak detector identifies gas inflow into a vacuum vessel using helium or sound waves. In the helium method, a small amount of helium is sprayed externally onto the target object, and helium leakage into the target is detected by a helium detector, pinpointing the leak. The acoustic method detects gas inflow by sensing sound generated during a leak, allowing contactless detection. However, the helium leak detector offers higher accuracy.