What Is a Relief Valve?

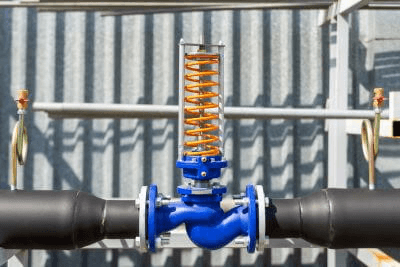

A relief valve is a safety device designed to control pressure and prevent damage to pipes and equipment. When the pressure in a system, such as a pump, exceeds a set limit, the valve opens to bypass the excess pressure, using a spring mechanism.

The valve’s opening pressure is determined by the spring’s strength and the pressure-receiving area of the valve. Regular inspection and maintenance of relief valves are crucial to ensure they function correctly and safely.

Uses for Relief Valves

Relief valves are critical in various applications where controlling abnormal pressure buildup is essential:

1. Automobiles

They are used in car air conditioning systems and hydraulic units in gasoline engine automobiles. In oil pumps, relief valves are installed to manage pressure build-up.

2. Gas Supply

In propane gas systems, such as those used for barbecues, relief valves maintain gas pressure within a safe range.

3. Manufacturing

Used in hydraulic systems and chemical plants, relief valves control pressure in systems and equipment such as hydraulic pumps, actuators, chemical reactors, and storage tanks, preventing damage from abnormal pressure.

Principle of Relief Valve

Relief valves function by using a spring-loaded spool that opens under excessive pressure, allowing pressure release. The setting pressure is adjustable by turning an adjusting screw.

Other Information on Relief Valves

Difference Between Relief Valve and Safety Valve

While both types fall under safety valves, their functions differ. Safety valves open fully at a set pressure for rapid pressure release, typically used with steam or gas. Relief valves gradually open as pressure increases, used mainly with liquids to adjust and control pressure. There are also safety relief valves that combine both functions, suitable for various applications and environments.