What Is an Agitator?

Agitators are machines that mix substances to achieve a goal. Agitators transfer rotational energy from a motor into the tank. The energy is used primarily for the discharge action, which creates a circulating flow throughout the tank, and the shearing action, which applies a local shearing force.

Agitators are machines that mix substances to achieve a goal. Agitators transfer rotational energy from a motor into the tank. The energy is used primarily for the discharge action, which creates a circulating flow throughout the tank, and the shearing action, which applies a local shearing force.

Agitator blades are the most important component of an agitator. The optimal agitator blade shape depends on whether discharge or shearing action is prioritized and how viscous the material is.

Typical agitator blades are propeller blades, turbine blades, anchor blades, paddle blades, and ribbon blades.

Uses of Agitators

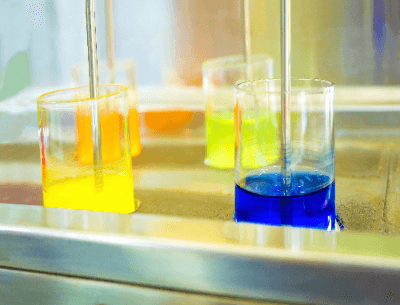

Agitators are used in industry to mix materials. In relatively large factories, the capacity of the agitator tanks is large, and the time required for agitation is correspondingly high.

Small Agitators, on the other hand, can be easily used from the laboratory level to the factory floor, etc., and can be agitated in a short time.

Most small agitators are used in agitation tanks with capacities ranging from 20 to 3,000 liters, and the size of the agitator blades is set according to the capacity.

Large Agitators are used at the factory level and are large in size at the 10,000L level and above. Therefore, it is necessary to devise ways to install multiple agitators in multiple tanks and to use agitators that can operate efficiently.

Principle of Agitators

State of Matter in Agitator

Diffusion and convection are necessary for mixing in a tank. Diffusion describes the phenomenon of spontaneous, detailed, and uniform mixing through molecular motion. Convection, on the other hand, describes a phenomenon in which different substances are stretched or divided within a tank and dispersed throughout the entire space when viewed as a large space.

Agitator Phenomenon

Assume that two liquids exist in two layers in a tank. When the agitator blades turn under the power of the motor, they first force the liquids to disperse finely. This is similar to shaking a dressing before using it.

Depending on the shape of the agitator blade, the liquid in contact with the agitator blade flows up, down, left, and right, resulting in the unique behavior of the agitator blade. For example, paddle blades are sloped and shaped to create more flow in the vertical direction. Turbine blades, on the other hand, have blades attached to a disk that rotate at high speed in the tank, producing high shearing force.

Agitator Power

As the motor rotates, power is transmitted to the shaft. At that time, if a reduction gear is attached, deceleration and torque increase according to the reduction gear. In addition, the shaft sealing device can seal the inside of the tank without interfering with rotation.

Generally, gland packings and mechanical seals are used as shaft sealing devices.

Types of Agitators

Agitator Composition

Agitators are used in many industries ranging from oil refining and petrochemical plants to cosmetics and food products. Because of their simple structure, including the installation of agitator blades, and cost advantages, they are used in a wide variety of industries.

The agitator consists of a simple structure, including the agitator tank, which holds the raw materials, the agitator blades, a motor to rotate the blades, and a shaft that transmits power to the agitator blades.

Agitator Tank Type

Agitators can be divided into three types according to the part of the structure described above where the raw materials are fed: tank type, duct type, and other types.

The tank type includes the one-rotating type, the reciprocating reversing type, and the vertical motion type. The one-rotating type can be further classified into vertical, bottom, horizontal, and portable types.

Details of One-Way Rotation Type

The vertical type of the one-way rotating type can be classified according to the installation position and angle of the agitator blades. It can be classified into centered/vertical installation, eccentric/vertical installation, and eccentric/tilted installation.

Similarly, the horizontal type of the one-way rotating type can be classified into two types: one in which the blades are installed horizontally on the tank wall of the agitation tank and one in which the blades are installed at an angle, and in both types, the agitation blades are often installed at the bottom of the tank.

Generally, horizontal agitation blades are mainly used for storage and blending tanks. This allows for agitation of the fluid flowing in from the bottom of the tank to achieve uniform concentration and temperature.

Other Information on Agitators

Types of Agitation Blades

Agitation blades used in the low viscosity range of substances are propeller blades, turbine blades, and paddle blades. On the other hand, anchor blades and ribbon blades are used in the high viscosity range. They are used for homogenization and heat exchange of high-viscosity liquids.

Agitation Blades Used in the Low Viscosity Range

Propeller blades are common agitator blades, similar in shape to a helicopter propeller.

Turbine blades are disks with blades and have high shear force, making them suitable for droplet refinement and gas-liquid dispersion.

Paddle blades are similar in shape to a ship’s oar and are widely used as materials for obtaining basic agitation data due to their simplicity.

Agitation Blades Used in the High Viscosity Range

Anchor blades are shaped like a ship’s anchor, and their disadvantage is that it is difficult to create flow in the axial direction.

Ribbon blades have a more complex structure, which allows axial flow to be formed.