What Is a Lubricator?

Lubricators are devices that supply lubricants such as oil and grease to machine parts and machinery.

A lubricator is a type of pneumatic equipment that supplies lubricant by atomizing lubricant into compressed air. By adjusting the amount of lubricant sprayed in advance with the attached adjustment knob, a certain amount of lubricant is automatically sprayed when compressed air is supplied.

Lubricators may not be required in some cases, as lubrication-free pneumatic devices have become widely used in recent years. Even if the actuator (e.g., air cylinder) is of the oilless type, lubricating it with Lubricator can extend its service life.

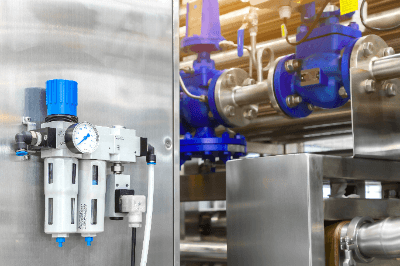

However, once lubricated, the grease in the sliding parts of the cylinder will be washed away by the lubrication, so continuous lubrication is necessary. Normally, the lubricator is installed at the compressed air supply position together with an air filter to remove moisture from the compressed air and an air regulator to adjust the supplied air pressure.

Uses of Lubricators

Lubricators are widely used in industry to improve machine reliability and simplify maintenance. They are most commonly used in pneumatic equipment.

Air cylinders are cylinders that operate using air pressure and require proper lubrication due to friction between the piston and the cylinder’s inner surface. Lubricators are used to lubricate air cylinders in the proper amount and at the right time to keep them running smoothly.

Another application is to lubricate valves. Air valves are valves that operate using air pressure and require proper lubrication because friction occurs at the contact surface between the valve and the valve seat. Therefore, solenoid valves for pneumatic control and air valves are lubricated by Lubricators to prevent deterioration.

In addition, it may also be used for mechanical parts. Mechanical parts such as reduction gears and bearings operate under high loads and at high RPMs, so lubricant must be supplied to these parts in the proper amount and at the right time. Conveyors, air compressors, and other mechanical devices also experience friction and can be properly lubricated with Lubricators.

Principle of Lubricators

The Lubricator is divided into a venturi section at the top and an oil tank at the bottom. When compressed air is supplied, the oil tank is pressurized, and the lubricating oil rises to the venturi section. As the compressed air expands through the venturi section, the lubricating oil also becomes oil mist.

Most Lubricators have a selective construction that allows only fine oil mist of 1 to 2 micrometers or less to pass through at the outlet port. The oil mist that passes through does not adhere to the pipe wall and can be supplied to equipment at a distance.

Because of the above structure, the pneumatic equipment is not supplied with oil when the lubricating oil in the oil tank runs out. If left unattended for a long period of time, this can lead to pneumatic equipment failure. Therefore, when using a Lubricator, the oil level must be checked and replenished periodically.

When used as a 3-piece set together with a filter and regulator, be sure to connect the filter, regulator, and lubricator in that order.

How to Select a Lubricator

When selecting a Lubricator, the amount of lubricant and lubrication method should be taken into consideration.

1. Amount of Lubricant

It is necessary to select a Lubricator that provides an appropriate amount of lubricant according to the specifications of the machine parts and equipment to be used. If the amount of lubricant is too little, wear of machine parts and equipment may increase.

On the other hand, excessive lubrication may result in wasted lubricant or the need to clean up excess lubricant.

2. Lubrication Method

Automatic lubricators are preferred for air lines, while manual lubricators can be used for simple lubrication.

As a precaution, some Lubricators may have restrictions on the types of lubricants that can be used. It is important to select the appropriate Lubricator to match the lubricant required by the machine part or device.