What Is a Reamer?

Reamers are tools used for finishing in hole drilling.

Reamers are tools used for finishing in hole drilling.

In hole drilling, a pre-hole with a smaller diameter than the target hole is first drilled with a cutting tool such as a drill. Reamers are used to finish the hole to the hole size and surface accuracy specified in the design.

Reamers are tools used for drilling holes, but they cannot drill holes by themselves. It is only a tool for finishing the pre-drilled hole.

Uses of Reamers

Reamers are widely used in holemaking, where high machining accuracy is required. Machining accuracy here refers to hole diameter, roundness, cylindricity, and surface roughness of the machined hole surface. Examples include the machining of sliding parts of machine parts and holes into which guide pins and positioning pins of dies are inserted.

Manufacturing parts that require such high machining accuracy holes include automobile and aircraft parts, molds, electronic parts and nozzles.

Principle of Reamer

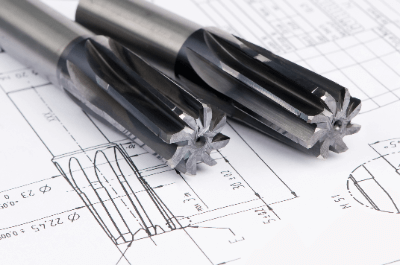

Reamers generally consist of a cylindrical or conical shaft with six to eight cutting blades around its periphery. The blades on the periphery are rotated by machine or manually to prepare the size and surface of the hole by shaving the sides of the hole to be drilled.

A drill has a cutting edge at the tip, which is pressed against the work surface while rotating the drill. Reamers have cutting edges only on the sides of the cylinder, not on the tip.

The amount of shavings that the reamer processes from the bottom hole is very small, less than 0.5 mm in diameter, even for a hole of about 50 mm in diameter. Depending on the diameter of the hole and the material to be finished, it is necessary to drill a pre-hole with an appropriate diameter to achieve an appropriate margin.

Types of Reamers

There are several types of reamers, depending on their purpose and usage.

Typical types are as follows:

1. Hand Reamer

Hand reamers are reamers used to finish holes by hand rather than with a drilling machine or other power-driven machine. The shank, or the part that grips the tool, is straight and the tip is square. This rectangular part is gripped by a tool with a handle, and the hand reamer is rotated by hand.

2. Chucking Reamer

Chucking Reamers are used on lathes, drilling machines, and screw machines. There are two types of chucking reamers depending on the shape of the shank: straight shank chucking reamers and tapered shank chucking reamers.

Reamers also have a chamfer-like shape at the tip that serves as a guide when starting machining. This part is called the bite area, and the angle of inclination is called the bite angle. The bite angle of a hand reamer is about 1°, which is very small, while the bite angle of a chucking reamer is about 45°.

3. Machine Reamer

Machine reamers, like chucking reamers, are attached to machines. The same is true for machine reamers, which are available with straight or tapered shanks. The difference from chucking reamer is that the length of the blade is longer.

4. Taper Reamer

Taper reamers are used to finish tapered holes. Tapered holes include holes for taper pins used to join two or more parts, and tapered holes for attaching cutting tools and other tools to the rotating shafts of drills, milling machines, and other processing machinery.

5. Spiral Reamer

A spiral reamer is a reamer that facilitates the discharge of chips produced by machining. Specifically, the blade is not straight but twisted into a spiral shape.

In addition, spiral reamers can finish the surface roughness of the hole sides to a low level. They are used in automotive and aircraft parts, especially in areas where hole positioning accuracy is important.