What Is an Anechoic Chamber?

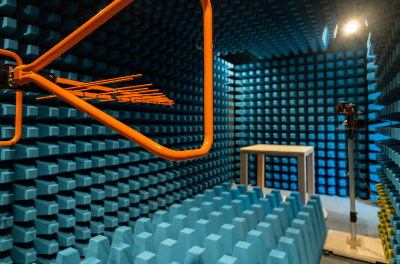

An anechoic chamber is a laboratory or research facility that does not leak electromagnetic waves outside and does not reflect them inside.

Reflection of electromagnetic waves is suppressed by installing a radio wave absorber inside the shielded room. Not only is there no leakage of electromagnetic waves to the outside, but the room is also unaffected by electromagnetic waves from the outside. The disadvantage of a shielded room is that it cannot prevent the diffuse reflection of electromagnetic waves in the interior space. An anechoic chamber, however, can prevent the diffuse reflection of electromagnetic waves and create an environment similar to a free space (open site).

In recent years, we are surrounded by many sources of electromagnetic waves, such as electrical and electronic equipment, wireless devices, and information systems, and there is concern that the electromagnetic waves generated by these sources may adversely affect peripheral equipment. Anechoic chambers, which block out the influence of the surrounding environment, play a major role in confirming the performance of wireless devices and electronic equipment such as smartphones and wireless LANs, as well as in noise testing.

Uses of Anechoic Chambers

Anechoic chambers can be used for acoustic measurements (e.g. sound power level measurements) of products that generate sound, such as automobiles, power trains, electrical equipment, and communication devices. The measurement methods, the configuration of anechoic chambers themselves, and their specifications are established by the ISO.

In recent years, there has been an increasing demand for large-sized hemi-anechoic chambers for pass-by noise measurements in automobiles. Combined tests are also conducted by adding wind tunnel test facilities and constant temperature and humidity facilities. The room can be used not only for physical measurement of sound sources but also for psychoacoustic experiments to evaluate the effects on human psychology and auditory perception.

Principle of Anechoic Chambers

An anechoic chamber is designed to block both external and internal electromagnetic waves. The outside of the chamber is shielded to prevent outside radio waves from entering to prevent malfunctions during testing, and the inside of the chamber has radio wave absorbers installed on the inside of the walls to prevent radio waves from being reflected inside the chamber.

To prevent the testing equipment from catching the radio waves reflected inside the room, the radio wave absorber on the wall surface absorbs the radio waves generated inside. The base of this anechoic chamber is a shielded room. Using a shielding material that not only absorbs within the material but also reflects on its surface, a great shielding effect is achieved by completely reflecting radio waves.

An anechoic chamber is a room in which electromagnetic wave absorbers are installed. Three types of characteristics are important for absorber materials: magnetic, dielectric, and resistive. It is necessary to determine these properties appropriately in light of the absorption bandwidth and other conditions to be achieved.

Ferrite is the mainstream material that satisfies these requirements. Ferrite utilizes the properties of magnetic loss, such as natural resonance and magnetic wall resonance, in response to high-frequency AC magnetic fields, and has the characteristic of suppressing the reflection of radio waves by converting the absorbed radio wave energy into heat energy inside the absorbing body.

Structure of an Anechoic Chamber

A typical anechoic chamber consists of glass wool made of a wire frame and thin cloth, placed in a wedge-shaped mold, with the inside of the room on the pointed side, and with no gaps between the ceiling, floor, and walls.

A room in which only the floor surface is not absorbing sound is called a semi-anechoic chamber, and can be used for measurements of automobiles and home appliances. The floor of an anechoic chamber is floated by means of a slatted steel frame or a wire stretched in a grid pattern. The entire room may be floated from the building by an elastic material.

Glass wool by itself is an excellent sound absorbing material, but when it is wedged, sound waves that reach the wedge surface are repeatedly reflected and absorbed by the surfaces of adjacent wedges, making it even more effective in sound absorption.

How to Select an Anechoic Chamber

1. High Sound Insulation Performance

An anechoic chamber is a completely sealed space, which completely shuts out (shuts out) sound from outside the room, making the room very quiet. This is because the background noise in an anechoic chamber is lower than the sound generated by the object under test. In order to measure a small sound, the sound insulation performance must be proportionally higher. Therefore, a rigid body such as concrete or sound insulation panels is necessary for the sound insulator or sound insulation layer in an anechoic chamber.

2. High Sound Absorption Performance

Sound generated from the object to be measured in the room is absorbed by the sound-absorbing surface. However, there is a difference in sound absorption between high frequency and low- frequency sounds. Basically, the lower the sound, the harder it is to absorb. Therefore, if an anechoic chamber is used to measure low sound, the sound-absorbing body must have a proportionally higher sound absorption performance. Therefore, the sound-absorbing body or sound-absorbing layer in an anechoic chamber requires a sound-absorbing wedge or a thick sound-absorbing block.

3. Space Saving

In order to achieve “high sound insulation performance” and “high sound absorption performance,” proportionally thicker layers are required. A full-scale anechoic chamber may be massive, with a sound insulation layer of 500 mm or more and a sound absorption layer of 1,000 mm or more, and requires a large space for installation.

In many cases, it is practically difficult to secure a large space in Japan. Conversely, in recent years, anechoic chamber manufacturers have improved their technology and developed anechoic chambers with thinner sound insulation and sound absorption layers. Since the layers are thin, installation space can be saved and the effective space in the room can be increased. In view of the above, anechoic chambers with thin and high sound insulation and sound absorption performance are required.

Other Information on Anechoic Chamber

1. Number of Surfaces of Anechoic Chambers

Anechoic chambers can be classified into two major types in terms of the structure of its construction: a six-sided anechoic chamber with absorbers installed on all six sides of the chamber (top, bottom, front, back, left, and right).

The other is a 5-sided anechoic chamber with absorbers on all 5 surfaces except the floor. 5-sided anechoic chambers are characterized by the fact that they do not have absorbers on the floor, assuming radio wave reflection on the ground (earth).

2. Performance Indicators of Anechoic Chambers

The size of the anechoic chamber, which determines the performance index of the anechoic chamber, is determined by various factors. For example, the size of the object to be measured, the frequency band to be shielded, and the standard of the test (10m method or 3m method, etc.). These factors will determine whether to put the equipment in an existing building or construct a new building. Since they are not inexpensive, careful consideration is required.

An important performance indicator for anechoic chambers is a property called Normalized Site Attenuation (NSA). As specified in CISPR 16-1-4, the maximum propagation loss is obtained when the transmitting and receiving antennas are placed facing each other, the height of the receiving antenna is moved between 1 m and 4 m, and the transmitting antenna is also moved within the specified range. The value must be within +/- 4dB compared to the theoretical value (value at the open site).

There is also a test called SVSWR (site voltage standing wave ratio), which requires that the maximum change in received level in an anechoic chamber with absorbers on all six sides must be less than 6 dB when the transmitting antenna position is changed within a specified range.