What Is an X-Ray Fluorescence (XRF) Analyzer?

X-Ray Fluorescence (XRF) Analyzer is a device that analyzes the content of an element by its X-ray fluorescence spectrum when an object is irradiated with X-rays.

X-Ray Fluorescence (XRF) Analyzers are used for qualitative and quantitative analysis of substances, and are utilized as a method of analyzing the composition of substances because they can be examined in a short time without destroying the sample.

X-Ray Fluorescence (XRF) Analyzer is a highly reliable inspection device because it can measure both solids and liquids and has relatively high sensitivity as a method of qualitative analysis.

Uses of X-Ray Fluorescence (XRF) Analyzer

X-Ray Fluorescence (XRF) Analyzers can perform qualitative and quantitative analysis of samples, both solid and liquid, in a nondestructive manner. They are especially used to determine the presence and content of toxic metals in alloy materials and soil.

For example, X-ray analysis is effective in examining the composition of materials of unknown composition, such as rocks and meteorites. Recently, printed wiring is being made halogen-free from the standpoint of environmental and safety preservation, and X-Ray Fluorescence (XRF) Analyzer is being used to assure this. Other applications include the qualitative and quantitative determination of hazardous chemical substances, and testing for substances specified by the RoHS Directive. Portable instruments that can be easily transported are also available, and their applications are expanding.

Principle of X-Ray Fluorescence (XRF) Analyzer

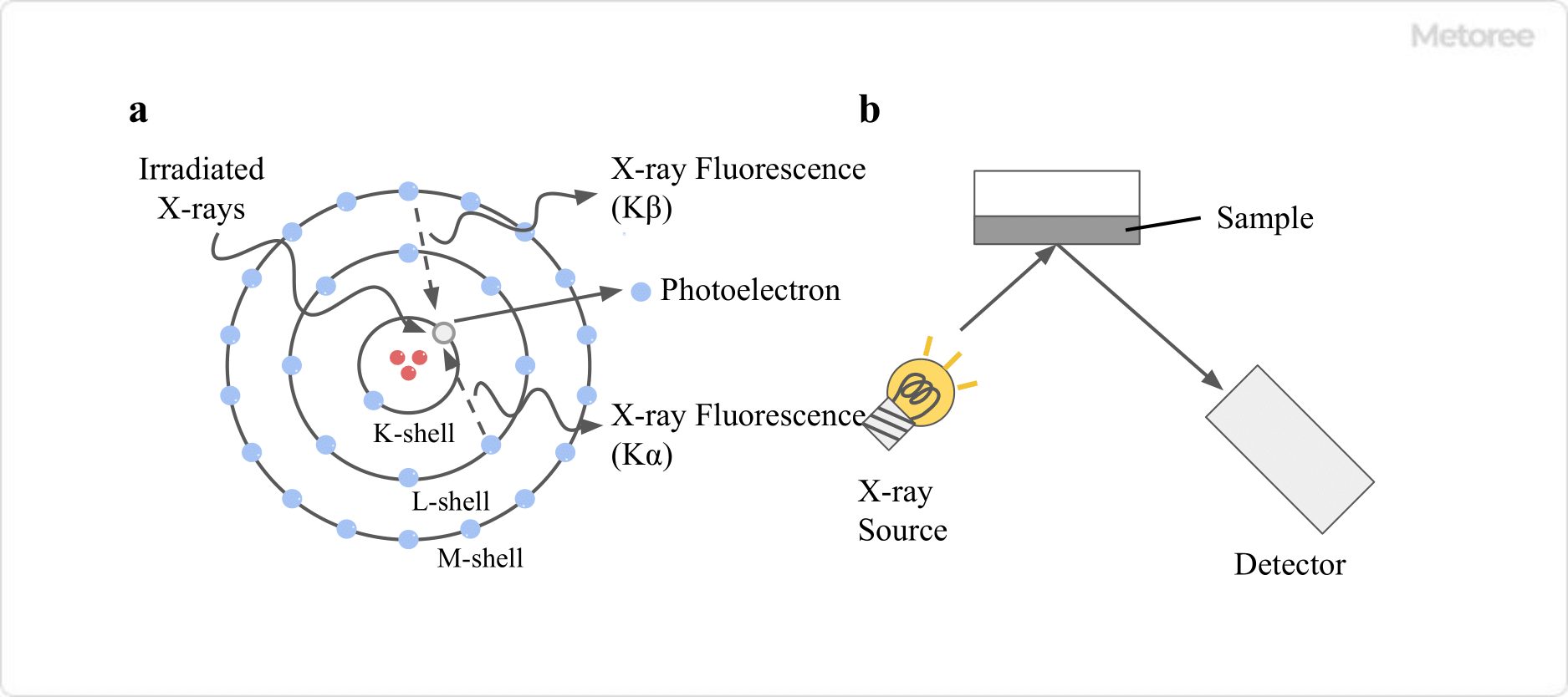

Figure 1. (a) Generation of X-ray fluorescence (b) Structure of the X-ray analyser

X-Ray Fluorescence (XRF) Analyzers measure the wavelength (or energy) and intensity of fluorescent X-rays emitted when an object is irradiated with X-rays.

When a material is irradiated with X-rays, its atoms absorb energy and are excited, emitting X-rays fluorescence. Since the wavelength (or energy) of X-ray fluorescence is unique to each element, it is possible to identify the type of substance from the wavelength of the detected X-ray fluorescence spectrum and to quantify it from its intensity.

X-Ray Fluorescence (XRF) Analyzer consists of an X-ray source that generates X-rays, a sample chamber that holds the sample, and a detection unit that spectra and detects the generated X-rays.

In the X-ray source, electron beams generated by applying high voltage are irradiated to a target such as tungsten to generate X-rays. The generated X-rays are irradiated to the upper or lower surface of the sample. At this time, the atmosphere in the sample chamber may be selected from atmosphere, nitrogen, vacuum, and other atmospheres.

X-Ray Fluorescence (XRF) Analyzers equipped with a sample observation mode allow the user to select the irradiation position while observing the sample. Elemental X-rays emitted from the sample are detected by the detector for qualitative analysis. In quantitative analysis, the intensity of the X-ray fluorescence is measured and the content rate is determined using a calibration curve or the fundamental parameter method (FP method).

There are two types of X-Ray Fluorescence (XRF) Analyzer spectroscopy and detection methods: wavelength dispersive and energy dispersive.

1. Energy Dispersive X-Ray Fluorescence (XRF) Analyzer

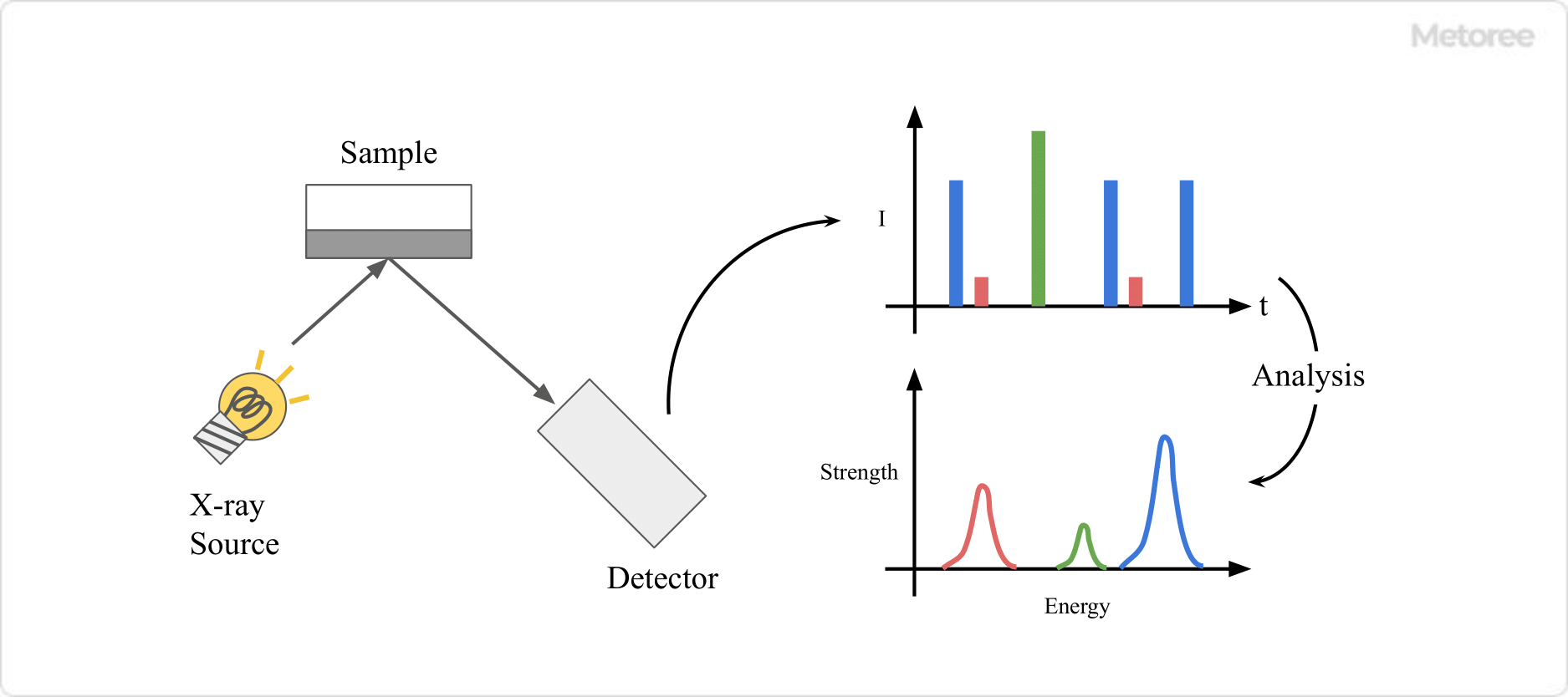

Figure 2. Measurement image of an energy-dispersive X-ray analyser

Energy-dispersive X-Ray Fluorescence (ED-XRF, or EDX, EDS) Analyzer is a method that measures the intensity of X-Ray Fluorescence in relation to its energy.

Specifically, the X-ray fluorescence incident on the detector is converted into a pulse current by a semiconductor in the detector, amplified, and the wave height is measured from the current value of one pulse. Since the energy of the incident X-rays is proportional to the current value, a graph of the intensity of the fluorescent X-rays versus their energy is obtained.

2. Wavelength-Dispersive X-Ray Fluorescence (Xrf) Analyzer

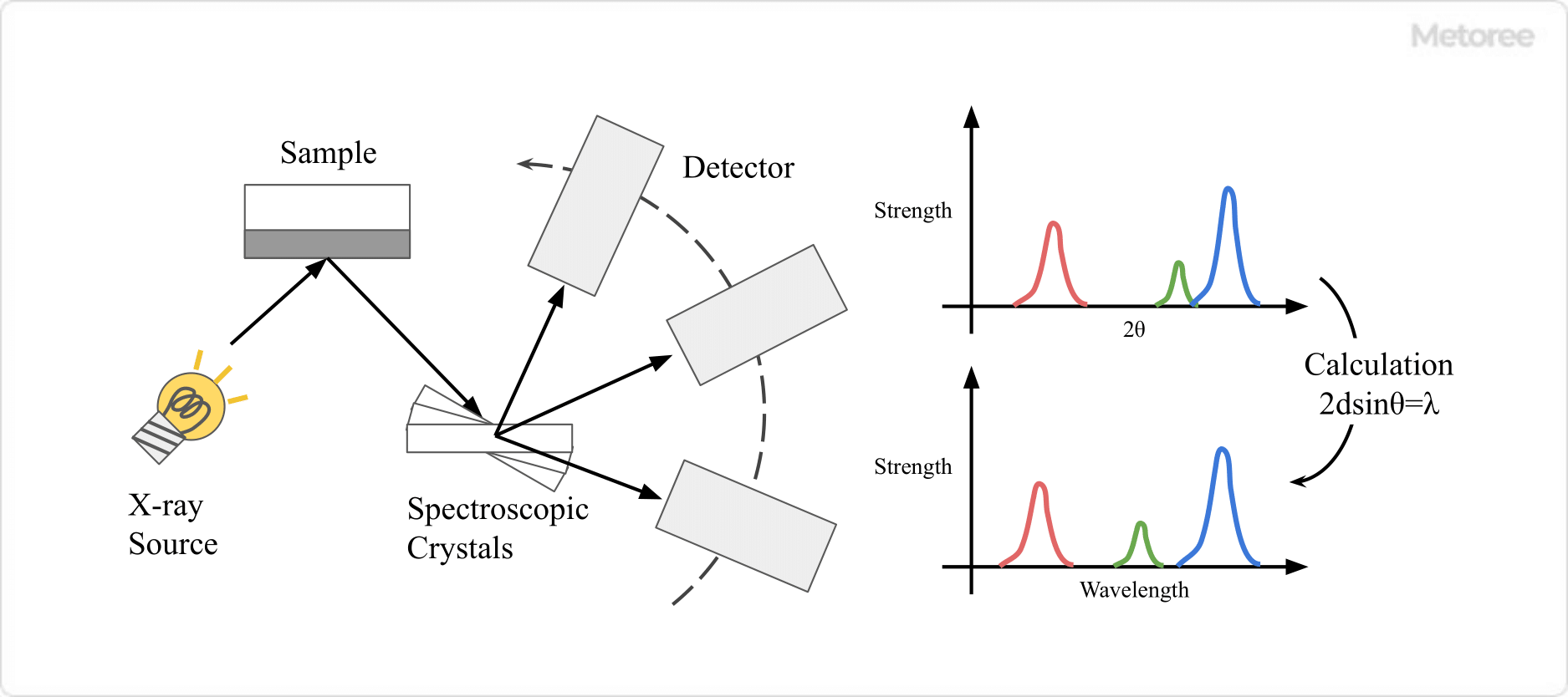

Figure 3. Measurement image of a wavelength-dispersive X-ray analyser

Wavelength Dispersive X-Ray Fluorescence (WD-XRF, WDX, or WDS) Analyzer measures the intensity of fluorescent X-rays in relation to their wavelength.

In the wavelength-dispersive type, X-rays emitted from a sample are spectrally split by a monochromator crystal and measured by a detector. Fluorescent X-rays incident on the spectroscopic crystal are strongly scattered in a certain direction according to the Bragg diffraction condition.

The Bragg diffraction condition is a law that states that when light of wavelength λ incident on a material with a lattice spacing d is scattered strongly in the direction of the diffraction angle 2θ, which satisfies 2dsinθ=nλ (θ: Bragg angle n: integer). In other words, since the face spacing d of the monochromator crystal is fixed, only X-rays of one wavelength are detected when the detector is located in the direction of diffraction angle 2θ, even if X-rays of various wavelengths are incident. By rotating the detector and measuring fluorescent X-rays at a wide angle, a graph of the intensity of fluorescent X-rays versus their wavelength can be obtained.

Other Information on X-Ray Fluorescence (XRF) Analyzer

Features of Energy-Dispersive and Wavelength-Dispersive Types

Energy-dispersive and wavelength-dispersive detection methods each have their own characteristics and should be selected appropriately according to the application.

1. Energy-Dispersive Type

The energy-dispersive type does not require spectroscopy, and the semiconductor detector can directly analyze the wavelength of the X-ray fluorescence, making it possible to reduce the size of the detector. Also, since multiple types of elemental analysis can be performed at once without the need for spectroscopy, measurements can be made in a short time. Because measurement can be made regardless of the shape or unevenness of the sample, it is sometimes used in conjunction with electron microscopes.

On the other hand, there are some disadvantages: the resolution tends to be low because the peaks of the obtained spectrum sometimes overlap, and it is difficult to detect elements that are contained only in trace amounts in the measurement object.

2. Wavelength-Dispersive Type

In the wavelength-dispersive type, fluorescent X-rays are spectrally split by a spectroscopic crystal and measured by a detector. Since the X-rays are spectroscopically separated by wavelengths, adjacent peaks can be easily separated, and the sensitivity and resolution tend to be high.

On the other hand, the system itself tends to be large and expensive due to its complex spectrometer system. In addition, the measurement takes longer than the energy-dispersive type because the diffraction angle is varied, and the sample surface must be smooth.