What Is a Needle Valve?

A Needle Valve is a valve with a stem (valve stem) that has a thin, pointed tip.

A Needle Valve is a valve with a stem (valve stem) that has a thin, pointed tip.

Needle Valves are characterized by their ability to accurately adjust the flow rate, not to mention their role as a stop valve that fully opens and closes the flow path. In general, however, they are intended for relatively low flow rates.

Uses of Needle Valves

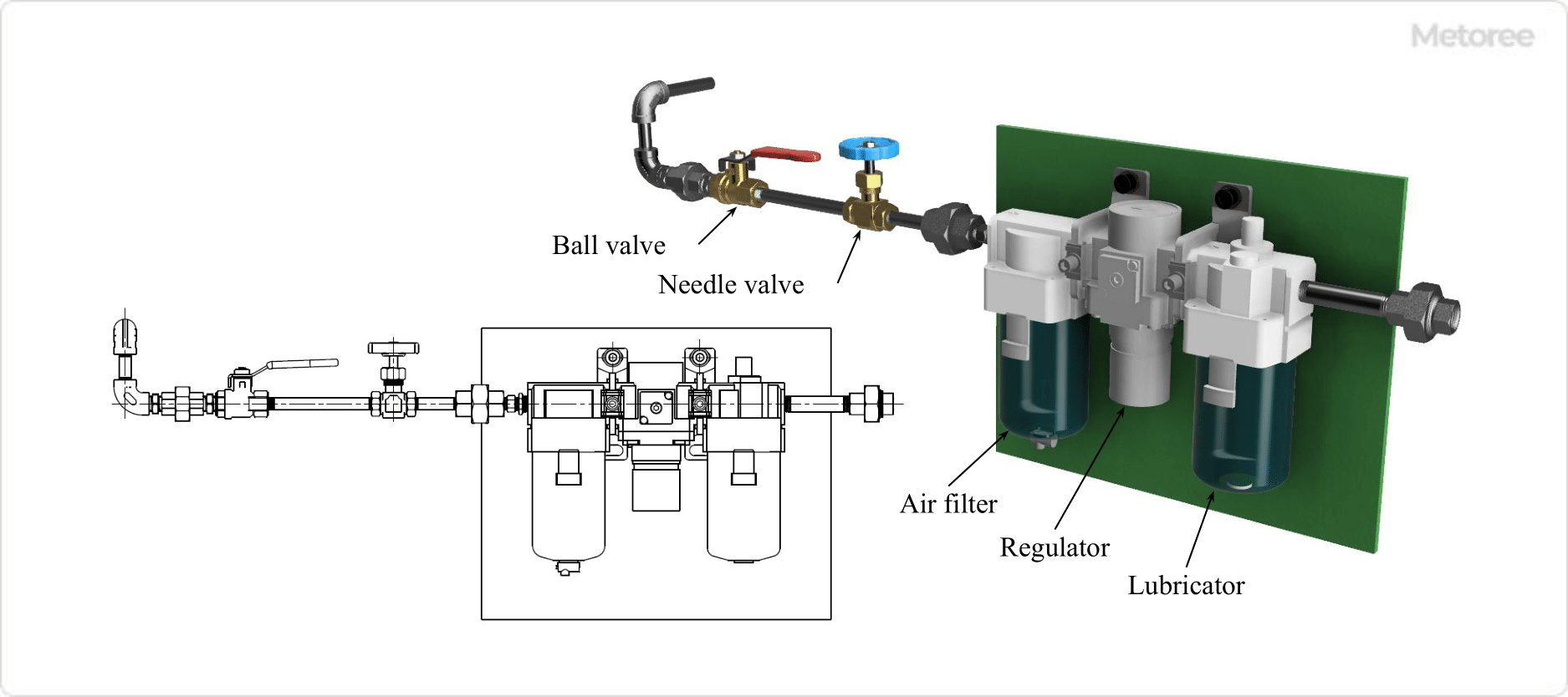

Figure 1. Example of needle valve use

Needle Valves are often used in flow control valve applications that require precise flow adjustment because of their superiority in adjusting flow rates. Therefore, they are rarely used in the fully open state. Most of them are used by adjusting the valve opening degree and fixing it at the required flow rate.

In particular, they are often used for flow control in minute areas or when the range of flow control is narrow. Normal globe valves (and some ball valves) can also control flow, but it is difficult to make very precise and fine adjustments, and they are generally used for flow control that does not require precision.

Needle Valves, however, can provide precise and fine flow control due to their internal structure specifically designed for flow control. For example, they are used in the semiconductor industry to adjust the amount of nitrogen purge, control air flow for opening and closing air cylinder valves and diaphragm valves, and stop valves for pressure gauge fluids.

Principle of Needle Valve

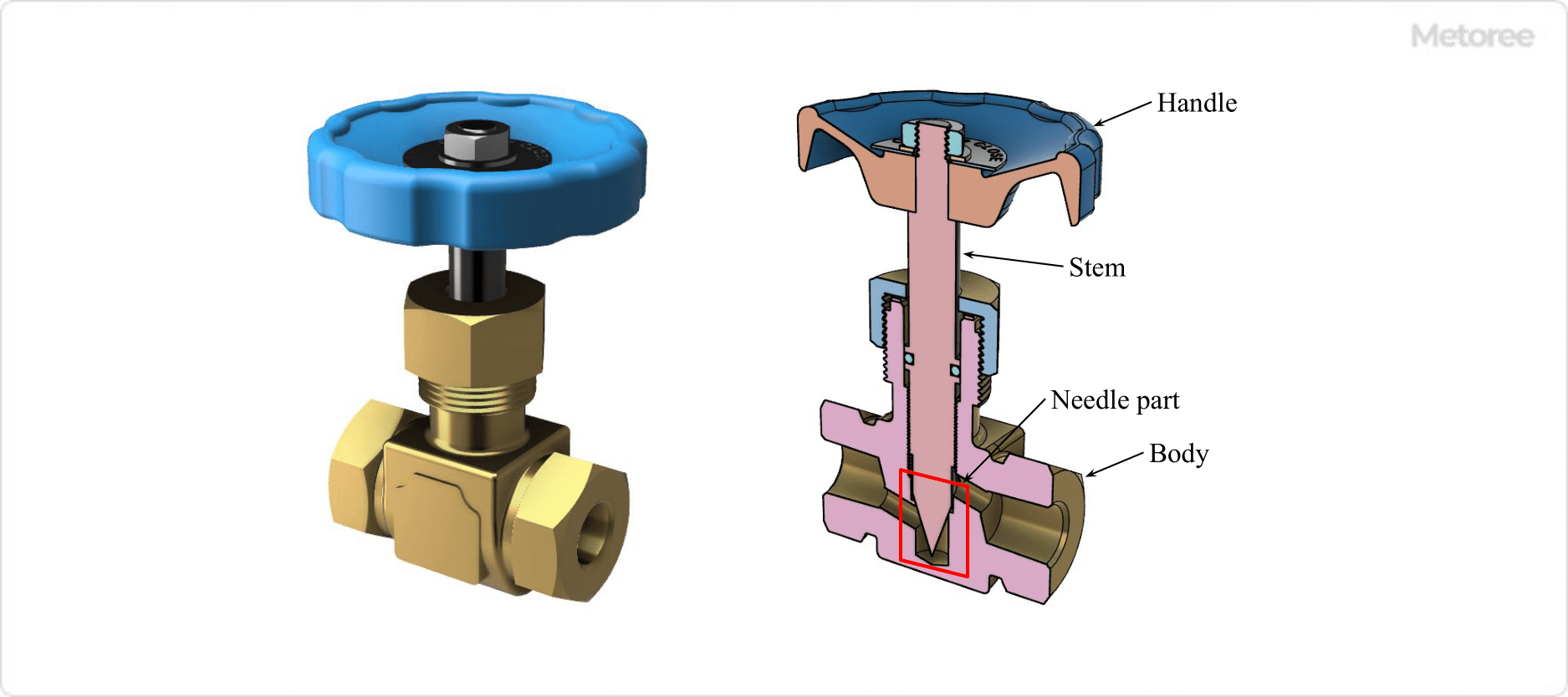

Figure 2. Structure of needle valve

The structure of a Needle Valve consists of a body (valve box), stem (valve stem), and handle.

The main feature of a Needle Valve is that, as the name suggests, the valve plug is needle-shaped. Globe valves, which have a similar structure, have a very large valve plug and are excellent for closing, but not for flow control.

In a needle valve, when the handle is turned to open the valve, the valve plug (needle) at the end of the stem rises and the opening between the valve seat and the flow path changes little by little. As a result, the flow rate changes little by little, allowing easy and accurate adjustment of the flow rate.

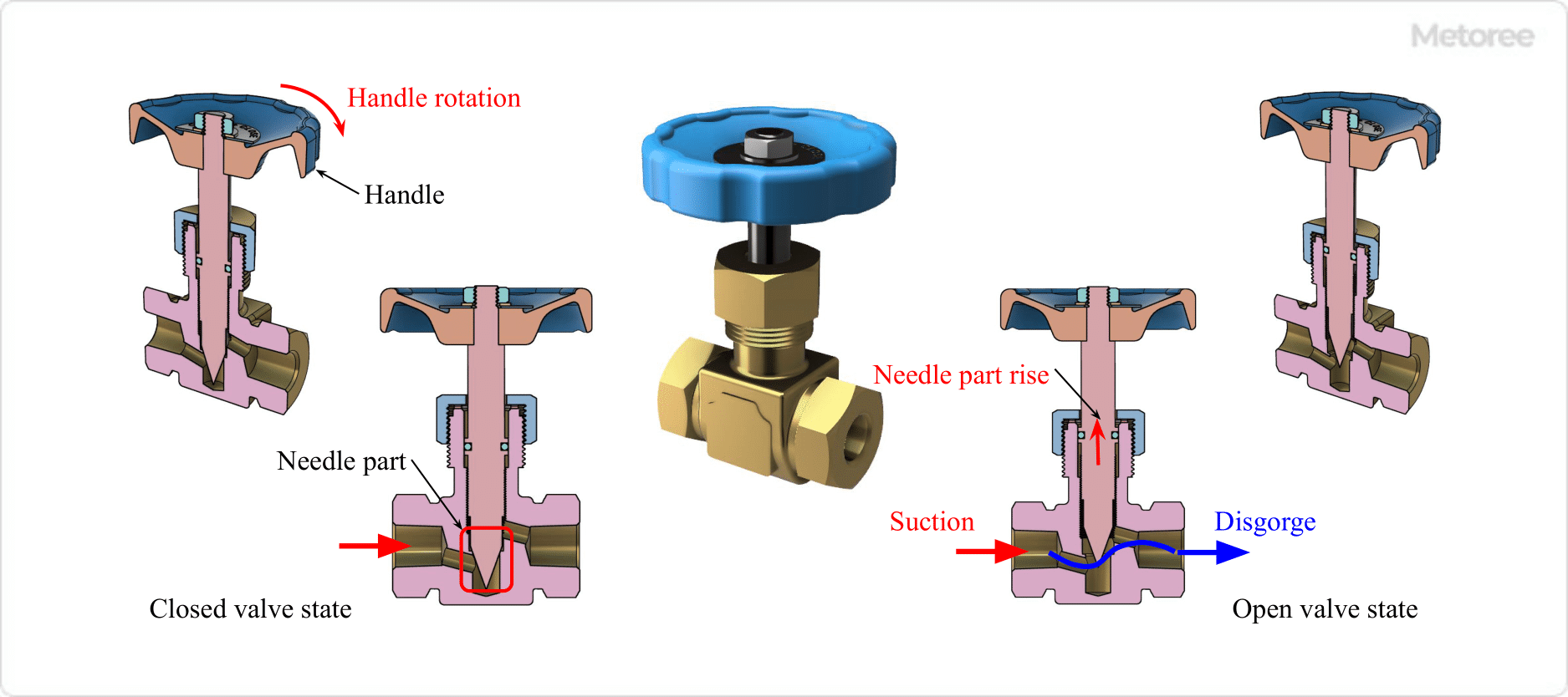

Figure 3. Needle valve opening/closing and fluid flow

Needle Valves can be used as stop valves for shut-off purposes. However, because it requires many turns of the valve stem to fully open and close, Needle Valves are not used for simple shut-off applications.

To completely and easily shut off the fluid, a stop valve, such as a globe valve or ball valve, is installed in the flow path to shut off the fluid.

Types of Needle Valves

Needle Valves are available in the following types:

- Open/Close type

Manual or automatic (electric actuator type or electromagnetic drive) - Piping connection method

Threaded (tapered pipe thread RC, NPT, etc.), flanged, ring joint, etc.

Automatic Needle Valves are used when opening, closing, and flow adjustment is required by remote control. An electric actuator is used to rotate the plug and stem to open and close the valve.

Some types use a stepping motor as the drive motor to enable precise and fine control. Stepping motors are motors that can control the angle of rotation by pulse signals, and are one type of motor that can guarantee high positioning accuracy.

Other Information on Needle Valve

Needle Valve Material

Brass is a material for general-purpose applications and is often used for low-pressure, non-high-pressure, low-flow applications such as air, cold and hot water, and oil.

Stainless steel is used, for example, in gas piping for silane and nitrogen trifluoride, which are commonly used in the semiconductor industry.