What Is a Hydraulic Clamp?

A hydraulic clamp is a device that secures workpieces, dies, jigs, or tools to machine tools like presses or lathes using hydraulic power. These clamps offer a significant reduction in setup time for high-diversity, low-volume production, providing an efficient alternative to traditional bolting methods.

Compared to air clamps, which utilize compressed air, hydraulic clamps provide stronger and more reliable clamping force.

Uses of Hydraulic Clamps

Hydraulic clamps are primarily used to fasten workpieces, molds, and jigs on machine tools. They find applications in machining centers for securing jigs and workpieces, as well as in presses and injection molding machines for die fixation.

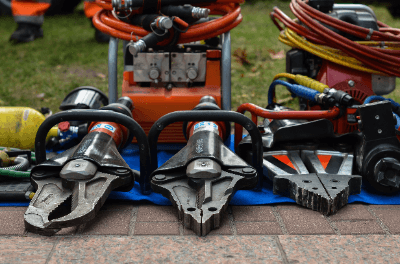

These clamps comprise a hydraulic clamp body and a hydraulic unit, which may be powered by a conventional electric motor-driven hydraulic pump or an air hydro booster. The latter converts and amplifies air pressure into hydraulic pressure, offering a compact and efficient solution. Additionally, solenoid valves and pressure switches are standard components for controlling clamping actions and ensuring adequate pressure levels.

Principle of Hydraulic Clamps

Operating on Pascal’s principle, hydraulic clamps generate strong clamping forces through hydraulic pressure. This method provides both high clamping force and rigidity while remaining compact. Hydraulic clamps are selected based on the object’s thickness, clamping force requirement, and T-slot size. Spacers can be used to accommodate objects of varying thickness within the clamp’s stroke range.

For easy maintenance and flexibility, many hydraulic clamps feature quick-disconnect hydraulic hoses. Proximity switches may also be employed to verify the proper positioning of the workpiece.

Other Information on Hydraulic Clamps

1. Energy Saving Measures With Hydraulic Clamps

Despite the shift towards electric clamping for environmental reasons, hydraulic clamps remain preferred for their ability to generate substantial pressure easily. To enhance energy efficiency, some models incorporate air clamps to halt the hydraulic pump once a specific clamping pressure is achieved or use disc springs for clamping force, resorting to hydraulic action only for unclamping.

2. Hydraulic Clamps With Switches and Sensors

Given their widespread use in machine tools, incorporating safety features like proximity switches or sensors in hydraulic clamps is crucial for operator safety. These features enable electrical interlocks to prevent accidents, ensuring safe operation. While clamps with positioning functions offer convenience, they may lack the clamping force of traditional hydraulic clamps and should be supplemented with additional positioning measures if precise mold or die positioning is required.