What Is a Vortex Flowmeter?

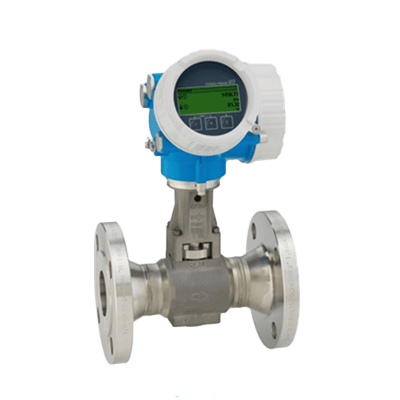

A vortex flowmeter is a flowmeter that utilizes the Karman vortex.

A Kalman vortex is a line of vortices generated downstream of an object (vortex source) placed in a fluid flow. The name “Kalman vortex” comes from the theoretical clarification by the physicist Kalman.

The vortex flowmeter is simple and robust in construction. Its main features are good accuracy, a wide flow range, and compatibility with a wide variety of fluids.

Uses of Vortex Flowmeters

The main applications of the vortex flowmeter are:

- Measurement of flow rate in steam piping

- Measurement of condensate recovery

- Measurement of boiler water supply

- Control of automobile engines

- Control of coolant flow in coolers

Vortex flowmeters can measure gas, liquid, and steam, so it can be used in any flow measurement scenario.

The caution is to select an appropriate bore size for vortex generation, since measurement is not possible without vortex generation. In the low flow range, the Karman vortex will not be generated and the flow rate cannot be measured.

Principle of Vortex Flowmeters

A vortex flowmeter measures the flow rate by counting Kalman vortices.

Since the frequency of the Kalman vortex is proportional to the flow velocity, the flow velocity can be determined by placing a vortex generating obstacle in the pipe and counting the vortices generated.

The following is an explanation using specific mathematical formulas.

Let the vortex frequency be f (Hz), the representative length of the vortex generating body be d (m), and the flow velocity be v (m/s),

f = S・v/d

The equation f = S・v/d, where S is the vortex frequency of the straw hatcher and v is the flow rate. where S is a proportionality constant called the Strouhal number. This number is determined by the shape and dimensions of the vortex generator.

The flow rate Q (m3/s), if the cross-sectional area of the pipe is A (m2),

Q = A・v = A・f・d/S = K・f

and if the constant of proportionality K between flow rate and frequency is determined in advance, the flow rate can be obtained from the frequency.

Actual vortex generators can be triangular, flat, or trapezoidal in shape, with the trapezoidal shape being considered the most accurate. The vortex is detected by converting the force generated by the vortex into an electrical signal using a sensor (piezoelectric element or semiconductor strain gauge), which is then amplified by a transducer and extracted as a pulse signal or an analog signal.

Other Information on Vortex Flowmeters

1. Straight Pipe Length of Vortex Flowmeters

Other meters that measure the flow rate of fluid in a pipe include differential pressure flowmeters and Coriolis flowmeters. The differential pressure flowmeter has a simple structure, but its disadvantage is that its measurement accuracy is somewhat low, while the Coriolis type has the disadvantage of being limited to the fluids that can be used.

A vortex flowmeter, on the other hand, measures the pressure change caused by the Karman vortex generated downstream of the vortex-generating object installed in the sensing section and converts it to the flow rate. A vortex flowmeter can measure liquids, solids, and gases, and is characterized by the simplicity of its instrumentation.

As is true of most flowmeters, the straight pipe section upstream of the instrument must be of a certain length for more accurate flow measurement. In vortex flowmeter, swirling flow or non-uniform velocity distribution in the pipe will affect the measurement. Therefore, the fluid must be laminar.

Therefore, the upstream of the flowmeter must be rectified, and valves, thermometers, pressure gauges, etc. must not protrude into the piping. The required length of the straight pipe section depends on the design of the piping.

2. Vortex Flowmeter and Steam

Differential pressure flowmeters are often used to measure steam flow. The differential pressure flowmeter has a simple mechanism, but its flow rate accuracy is inferior to that of other flowmeters.

In such cases, a vortex flowmeter can be used to measure the flow rate of steam accurately.

In the case of steam, the density varies with temperature and pressure. A vortex flowmeter not only provides accurate measurement of flow rate, but some meters are equipped with a temperature sensor to enable conversion to mass flow rate.

In addition, a vortex flowmeter is more suitable than the differential pressure type, mainly because in boilers the steam is wet steam. However, the effects of temperature, pressure, and dryness of this wet steam can result in low accuracy even in a vortex flowmeter.

Vortex flowmeters for steam have a built-in dryness sensor in the detection section and are designed to be able to convert the mass flow rate.