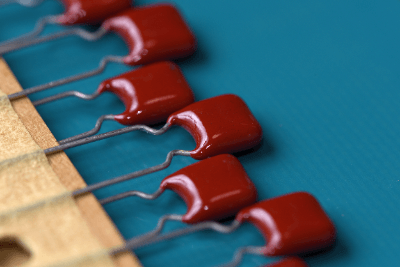

What Is a Film Capacitor?

A film capacitor is a capacitor that uses plastic film as a derivative. The technology traces its roots back to paper capacitors invented in the late 19th century. In paper capacitors, oil or paraffin paper is clipped onto aluminum foil and rolled.

The type that is rolled by depositing metal directly onto paper is called a metalized paper (MP) capacitor. Film capacitor was developed in the 1930s based on these technologies.

Film capacitor is classified into foil electrode type and vapor-deposited electrode type (metalized film type) according to the structure of the internal electrodes, and further into wound type and laminated type, inductive type, and non-inductive type according to the difference in structure.

Uses of Film Capacitors

Film capacitors are used in a wide variety of products from consumer products to industrial equipment. Examples of consumer products are home appliances such as refrigerators and in-car electronic equipment such as car navigation systems, car audio systems, and ETC systems. Examples of industrial equipment include power electronics equipment.

Film capacitors are characterized by high insulation resistance and high safety. They are also non-polarized, have excellent high-frequency characteristics, and have good temperature characteristics. In addition, film capacitors have high capacitance accuracy and a long service life.

However, film capacitors are larger than multilayer ceramic chip capacitors. Therefore, film capacitors tend to be used in voltage and capacitance ranges that cannot be covered by ceramic capacitors, as well as in high-performance and high-precision crises.

Principle of Film Capacitors

Capacitors are electronic components that store and release electricity. When voltage is applied between opposing conductors, electrostatic induction occurs in the insulator or space between them. The electrostatic induction action causes dielectric polarization in the insulator, which charges the battery.

Film capacitors use a film as the inductor. Film capacitors can be classified into several categories according to the construction and structure of the internal electrodes.

1. Foil Electrode Type Film Capacitors

These are wound film capacitors in which a plastic film is wound over a metal foil that serves as the internal electrode. The metallic foil is made of aluminum, tin, or copper.

There are two types of foil-electrode film capacitors: inductive and non-inductive. The inductive type is wound with a lead wire attached to the internal electrode, while the non-inductive type has a lead wire or terminal electrode attached to the end face. The inductance component of the non-inductive type can be smaller than that of the inductive type, resulting in superior high-frequency characteristics.

2. Evaporated-Electrode Film Capacitors

This is a type of film capacitor in which the internal electrode is made by vapor-depositing metal onto plastic film. Aluminum or zinc is used as a metallic material. Since the vapor-deposited film is very thin, this type of capacitor can be made smaller than the foil electrode-type film capacitors.

Other Information on Film Capacitors

1. Polarity of Film Capacitors

Film capacitors do not have polarity. In other words, film capacitors are non-polarized capacitors. There are two types of fixed capacitors: non-polarized capacitors and polarized capacitors.

Non-Polarized Capacitor

A non-polarized capacitor is a capacitor whose terminals do not distinguish between positive and negative. It does not matter which terminal is positive. The polarity of the voltage applied to the terminals is not regulated. Non-polar capacitors can be used directly in AC circuits.

Film capacitors are one of the mainstream nonpolar capacitors. Other non-polar capacitors include ceramic capacitors, paper capacitors, mica capacitors, and air capacitors.

Polarized Capacitors

A polarized capacitor is a capacitor with two terminals, one of which is positive. If the polarity of the terminals is used incorrectly, the capacitor will be damaged.

2. Film Capacitors and Audio

Audio equipment can be self-made or customized to one’s taste in sound. Multiple factors affect the quality of sound, but the parts used also affect the sound quality. Capacitors are one of those parts.

The characteristics required of capacitors used in audio amplifiers include the following:

- Good high-frequency characteristics

- Low harmonic distortion

- Low so-called squeal

Compared to electrolytic capacitors, film capacitors are superior in the above characteristics. In terms of sound quality, film capacitors have better sound transparency and resolution than electrolytic capacitors.