What Is a Strain Gauges?

A Strain gauge is a device that measures the strain of an object. They have also been used in pressure gauges and force gauges because they can measure strain and calculate pressure, load, etc.

Uses of Strain Gauges

Strain Gauges are used to measure the strain of products whose strength is directly affected by strain, to measure loads in production plants, and to measure the degree of deformation of molds and other components. However, care must be taken to ensure that the strain cages are installed in the correct orientation, otherwise, measurement errors will occur.

Specific examples of use include the following.

- Measurement of strength and strain of printed circuit boards

- Monitoring and measuring the load on press equipment

Principles and Types of Strain Gauges

1. Principle of Strain Gauges

Strain cages are used by attaching them to the object to be measured, which is then strained along with the object to be measured, resulting in a change in the internal electrical resistance. The strain is calculated by measuring the amount of change in the electrical current.

2. Types of Strain Gauges

There is a great variety of strain gauge types. The most widely used are foil strain gauges, wire strain gauges, and semiconductor strain gauges.

Other features of strain gauges include those suitable for low and high-temperature environments, those capable of measuring finer strains, and those made of materials suitable for various materials to be measured.

Structure of Strain Gauges

The structure of “foil strain gauges” and “semiconductor strain gauges” are described below.

1. Foil Strain Gauges

The structure of foil strain gauges, the most popular type of strain gauges, consists of a metal foil attached in a zigzag pattern on an insulator base, with two wires coming out of the metal foil. These two wires are connected to a circuit called a Hoinston bridge circuit.

The Hoinston bridge circuit is a circuit in which three resistors of known resistance and four strain gauges are arranged in a bridge configuration, and the resistance of the strain gauges can be measured by measuring the potential difference between the center of the resistors and the strain gauges.

When the object to be measured to which the strain gauges are attached is distorted, the foil of the strain gauges attached expands or contracts, resulting in a change in the value of electrical resistance, and the amount of change in resistance is obtained from the potential difference in the Hoisington bridge circuit. Since strain gauges have a gauge factor, which is an intrinsic value of the amount of change in resistance to strain, it is possible to calculate the strain of the object to be measured from the gauge factor and the amount of change in resistance.

2. Semiconductor Strain Gauges

Semiconductor strain gauges are strain gauges that utilize a semiconductor in the foil portion of a foil strain gauge. They utilize the property that the electrical resistivity of a semiconductor changes when stress acts on the semiconductor.

Other Information on Strain Gauges

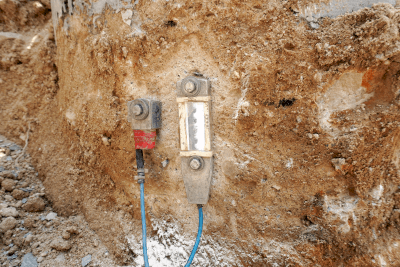

1. How to apply Strain Gauges

The accuracy of strain measurement using strain gauges strongly depends on the method of gauge installation (adhesion in most cases). Therefore, it must be very careful when attaching strain gauges to a measurement object. The first step is to clean the surface of the measurement target to which the gauge is to be attached.

It is best to use an oil-based detergent to remove oil thoroughly. Failure to do so will allow oil to penetrate deeper into the material when the surface is ground or polished during application. After cleaning, lift the gauge with tweezers and carefully adhere it to the surface to be measured.

At this time, it is important to ensure that all empty bubbles between the surface and the gauge are pushed out so that they can be affixed. In this state, wait a few minutes for the adhesive to harden. After a few minutes have elapsed, finally wrap the entire surface with insulation tape to protect it from damage, and the pasting is complete.

2. Drawbacks of Strain Gauges and how to solve them

The advantage of strain gauges is that they can easily measure strain simply by bonding them to the object to be measured. In reality, however, there are many complex factors involved that make measurement more difficult. For example, the problem of stress is one of them.

Strain changes due to the material’s interaction between externally applied forces and internal stresses. Therefore, analysis of strain in two or three directions requires using “rosette strain gauges,” which are a combination of multiple gauges.

In addition, depending on the coefficient of thermal expansion of the material constituting the measurement object, the strain may be determined to have occurred even if there is no actual strain. To prevent this, it is necessary to match the material of the gauge with the material to be measured.

In strain measurement with strain gauges, the best one must be selected from among many types of gauges based on a good understanding of their physical or mechanical characteristics.

3. Strain Gauges and Temperature Compensation

The major factors affecting strain gauges bonded to the measurement object are strain caused by external forces and temperature change. When temperature changes occur, the strain gauges are affected by the difference in the coefficient of linear expansion between the measurement object and the strain gauges, and by the change in resistance of the strain gauges due to temperature.

The measurement of strain as if it is caused by temperature change is called apparent strain. The use of self-temperature compensating strain gauges is the most effective countermeasure against apparent strain. Self-temperature compensating strain gauges are strain gauges in which the temperature coefficient of resistance of the strain gauges is adjusted to suit the measurement object to minimize the amount of apparent strain due to temperature.

Selecting the appropriate strain gauges for the measurement object is the best choice, but it may leave some errors. In some cases, they have nonlinear characteristics. In most cases, this error is noted on the data sheet of the strain gauges, and if more precise measurement is required, a compensation calculation can be made to account for the error calculated from the datasheet.

4. Strain Gauges and Creep Compensation

Creep is a phenomenon in which strain increases with time when a constant load is applied under certain temperature conditions. The creep phenomenon is the natural enemy of strain gauges, and if it occurs, it may directly lead to measurement errors.

In most cases, the creep phenomenon of strain gauges is caused by the base material, grid shape, and adhesive. Therefore, a common method is to cancel the effects of creep phenomena on each other by using a strain generator in the opposite phase of the creep caused by these factors as the material creep and attaching strain gauges to it.

The important point is the combination of materials. If the creep phenomena are in opposite phases, but their absolute values are very different, they cannot be canceled, and the effect will be in one direction. Note that, depending on the material, creep phenomena are more pronounced at higher temperatures in most cases. Please remember that the higher the stress applied to the strain gauges, the shorter the time to rupture (life), considering the increase in strain due to the creep phenomenon.