What Is an Angle Valve?

An Angle Valve is a valve that can be connected to a pipe at a vertical angle when the valve body is connected to the pipe.

It is a type of valve used in piping and conduits. Angle Valves have the advantage of being easy to install and maintain due to their structure.

Angle valves are also used in a wide range of applications because of their resistance to high temperature and high pressure fluids, depending on the material used. In addition, a variety of shapes and sizes are available, depending on the type of valve and its application.

Uses for Angle Valves

Angle Valves are used as piping for water, air, oil, and steam. They are useful in situations where space saving is required, such as boilers.

1. Piping System

In piping systems such as water and gas pipes, angle valves are used to control the flow of fluids. The purpose of water pipes is to stop the passage of water. In gas pipes, they are used to stop the passage of gas.

2. Machinery Industry

In the machinery industry, such as ships and automobiles, they are used to control hydraulic pressure. On ships, it is used to control the hydraulic pressure of the diesel engine that powers the ship, while in automobiles, it is used to hydraulically transmit the operation of the car’s steering wheel.

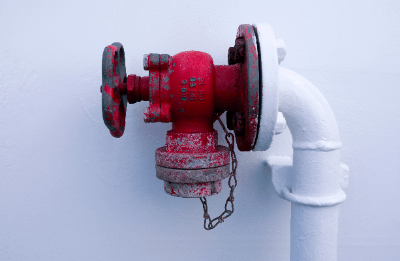

3. Fire Prevention Systems

In fire prevention systems, they are used to control fire extinguishing systems. Angle Valves are used to control the flow of extinguishing agents and to extinguish fires at an early stage.

Principle of Angle Valve

Angle Valves regulate the passage of fluid by opening and closing a valve. The valve mechanism of an Angle Valve is located inside the valve body and is generally disk-shaped or cone-shaped. It can be operated with a lever or handle, and the amount of fluid passage can be regulated by opening and closing the valve.

When the valve is closed, the passage of fluid is stopped, and when the valve is opened, fluid is allowed to pass. Angle Valve plugs are made of a variety of materials. Typically, materials such as metal and plastic are used. It is important to select the appropriate material depending on the environment in which the valve is used and the type of fluid.

The opening and closing of Angle Valve is done by the rotary motion of the valve. When the valve opens and closes, the flange at the connection between the valve body and the pipe is used to rotate the valve. Rotation of the valve regulates and freely controls the amount of fluid that passes through it.

Types of Angle Valves

Angle Valves are mainly classified into the following types: bronze brass type, cast iron type, cast steel type, and stainless steel type.

1. Bronze Brass Type

Suitable for valves that require excellent corrosion resistance and airtightness. Widely used in housing, agriculture, and industry. The disadvantage is the high cost of ingots. Additionally, it cannot be used for flammable or toxic gases.

2. Cast Iron

Due to its excellent workability and low ingot cost, it can be used for valves of medium to large diameters (1,000A or larger). However, it has the disadvantage of being susceptible to corrosion. Because of its low cost, it is widely used as a general-purpose product.

3. Cast Steel Type

This type of steel has high strength and can be selected according to the temperature of the fluid. It is used in petrochemical plants, thermal and nuclear power plants, and other places that handle high-temperature, high-pressure fluids. However, it is somewhat susceptible to corrosion.

4. Stainless Steel Type

Resistant to corrosion, and can be used in a wide range of applications from low to high temperatures. It is a widely used material with high strength. However, its high ingot cost is a disadvantage.

How to Select Angle Valve

1. Intended Use

The materials and valve shapes used may differ between applications in piping systems, such as water and gas pipes, and applications in the machinery industry, such as ships and automobiles.

2. Material

It is also important to select a material that is appropriate for the type of fluid. For use in highly clean areas such as food factories and medical equipment, a material with excellent corrosion resistance such as stainless steel should be used.

3. Size of Connecting Parts

The size of the connection part is also an important factor. If the size of the connection part does not match the pipe, it may not operate properly. Select the appropriate size according to the connection piping and fluid flow rate/pressure.

4. Operating Environment

If the valve is to be used in a high-temperature, high-pressure environment, the material and heat resistance performance of the valve must be considered.