What Is a Safety Light Curtain?

Safety light curtains are light sensors that monitor the intrusion of people into a facility.

They are mainly installed at entrances to facilities, and in hazardous areas to provide safety measures for workers. Due to their safety-critical nature, many products are designed and evaluated in accordance with the international standard IEC61496-1/2, General Safety Standard for Sensors, and are certified as safety equipment by a third-party certification body.

Uses of Safety Light Curtains

Safety light curtains are one of the main safety devices used in industry.

The following are examples of where safety light curtains are used:

- Around press machine openings

- Around product inversion equipment

- Around the openings of crushers and sorting machines

- For security in museums, safes, etc.

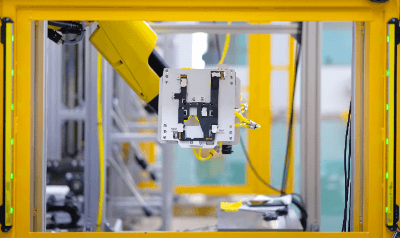

They are often used to detect human intrusion in the vicinity of large drive machines. Also, safety light curtains prevent accidents caused by being caught or entangled in machinery.

In general, large drive machines are covered with fences or railings to make them physically impenetrable. However, it is inconvenient to cover areas completely that are frequently accessed by people or require regular maintenance. In such areas, safety light curtains are installed to shut down the equipment in case of human intrusion.

In addition to industrial applications, safety light curtains are sometimes used in museums where people frequently enter and leave the building and security is required at night.

Principle of Safety Light Curtains

Safety light curtains consist of a light sensor, an enclosure, and lead wires.

1. Light Sensor

Light sensors are generally composed of a pair of light-emitting and light-receiving units. The mechanism is similar to that of photoelectric sensors and laser sensors, where the light-receiving device detects an object by blocking the projected light and transmits a signal. The optical axes must be aligned, so that multiple projected parallel beams of light are received.

The light source of the floodlight is specified to use a wavelength range of 400 nm to 1,500 nm. LEDs that output infrared rays with a wavelength of about 900 nm are mainly used.

In the case whereby the sensor of safety light curtain malfunctions, the safety device will operate to shut down the equipment if it detects an abnormality. The health signal is mixed with the light sensor, and if it is not received within the response time, a failure signal is sent out as a circuit failure.

2. Enclosure

The enclosure is an outer shell which is to protect the optical sensor and internal circuit boards. Generally, hard synthetic resin or metal is used. It may be painted with a tiger stripe pattern to indicate that it is a safety measure product.

3. Lead Wires

Lead wires are components used to connect sensors to external control devices. Generally, a multi-core Moving-cable or the like is used. It is often a connector cable.

How to Select a Safety Light Curtains

Selection criteria for safety light curtains include detection height, optical axis pitch, and detection distance.

1. Detection Height

The detection height is the width of the safety light curtain from which the light beam is emitted. It is selected according to the size of the opening.

The larger the detection height, the wider the area to be detected; but the more expensive and the larger the device, the more uneconomical it becomes. Generally, the size of the aperture should be kept to a minimum and the size of the safety light curtain should be reduced.

2. Optical Axis Pitch

The optical axis pitch is the distance between the emission of the optical axis. Also referred to as the minimum detectable object, the shorter the value, the more likely it is to detect even small material intrusions. However, the shorter the optical axis pitch, the more expensive it is.

In order to detect hand intrusion, a 20 mm to 40 mm width is select while 40 mm or more is selected for the detection of arm or human body intrusion.

3. Detection Distance

Detection distance is the distance between the projector and receiver. It is selected according to the size of the opening. Generally, the longer the detection distance, the more expensive the product tends to be.

There are products with short detection distances of 5 m or less. Products capable of detecting over 50 m at the maximum are also available. In general, the shorter the detection pitch, the shorter the detection distance tends to be.

Other Information on Safety Light Curtains

Functions of Safety Light Curtains

Safety light curtains ensure safety, but there are muting and blanking functions that can be partially disabled. However, care must be taken when using these functions, as incorrect use can lead to fatal accidents.

The muting function temporarily deactivates the safety light curtain. This is done for a portion of the detection area. For example, if a product or part is being manufactured and passes through the safety light curtain, only the part that passes through the safety light curtain will be made non-detectable.

Blanking function is a function that disables a portion of the safety light curtain at any time. It is used in equipment where the optical axis is constantly blocked by a fixed object such as a workbench.