What Is a High Frequency Welder?

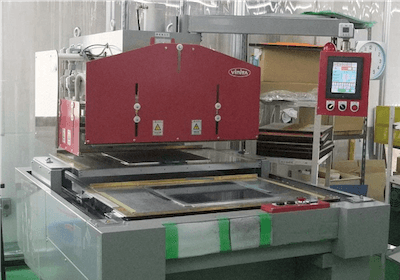

A high frequency welder is a device that welds materials using high frequency dielectric heating.

It is suitable for thermoplastic resins like polyvinyl chloride (PVC) and nylon. Welding with a high frequency welder offers higher weld strength and a cleaner finish compared to other external heating methods.

Unlike microwave heating, a high frequency welder can achieve targeted and deeper heating by using electrode plates to heat the material between them.

Uses of High Frequency Welders

High frequency welders are utilized to bond sheet materials, including:

- Tents and life jackets.

- Business card cases and book covers.

- Bags made of artificial leather.

- Exterior packaging for seasonings and toothpaste.

Due to its operating principle, the range of materials compatible with a high frequency welder is limited. However, the seamlessness of the welds results in a visually appealing finish, making it ideal for aesthetically sensitive products and ensuring airtightness and waterproofness for items like tents.

Principle of High Frequency Welders

A high frequency welder generates heat through dielectric heating, where a high-frequency voltage agitates the material’s molecules to create frictional heat, uniformly warming the material from inside. This method is effective only for dielectric materials such as vinyl chloride and polyethylene.

By applying high frequency voltage and pressure between electrodes, the material is heated to 248-266°F within seconds, reaching a semi-liquid phase. Cooling under pressure then allows the materials to fuse together.

Other Information on High Frequency Welders

1. The High Frequency Welder Process

This process is notable for not causing appearance defects like scorching, as it heats the weld area locally without affecting the surroundings. The process is smoke-free and does not emit harmful substances, offering a safe and environmentally friendly solution.

2. Materials to Be Welded With High Frequency Welder

Main materials include:

- PVC (Vinyl Chloride): Commonly used for vinyl sheets and artificial leather due to its softness and thermal processing ease.

- TPU (Thermoplastic Polyurethane): Chosen for its elasticity in items like hoses and smartphone case bumpers.

- POF (Polyolefin): Includes polyethylene and polypropylene, used for packaging bags for condiments and toothpaste.

3. High Frequency Welder Frequencies

Selection of power and frequency depends on the material and thickness of the object. Frequencies range from 40 MHz to 200 MHz for plastic sheets, and 10 MHz to 50 MHz for thermosetting plastics, with 2.45 GHz also being used for specific applications.

4. Price of High Frequency Welders

Prices vary widely based on size and output capacity, with smaller units starting around 3,000,000 yen and larger equipment for industrial use ranging from 5,000,000 to 10,000,000 yen.