What Is Spot Welding?

Spot Welding is a type of welding method along with Arc Welding and Gas Welding.

Spot Welding is a type of welding method along with Arc Welding and Gas Welding.

Two pieces of welded material are sandwiched between electrodes under pressure, and a large current is applied. Then, the metals are joined together by melting and solidifying in a spot manner due to electric resistance heat.

There are three basic types of welding methods: pressure welding, brazing, and fusion welding.

Spot Welding is categorized as pressure welding. Unlike arc welding, which forms a wide bead (welding surface), spot welding joins only one small point, resulting in a clean finish.

Spot Welding is also called Resistance Spot Welding because the base metal is heated by electrical resistance.

Uses of Spot Welding

Spot Welding is used to join parts of automobiles, railroad cars, and household appliances because of its ability to maintain a clean appearance.

One of the advantages of Spot Welding is that, unlike other welding methods, it welds directly across the base metal and does not require any fusing materials such as shielding gas or flux.

Another advantage of Spot Welding is that even novice welders can easily perform spot welding, whereas arc welding and gas welding are dependent on the skill of the welder. Spot Welding can be combined with a robot arm to automate the welding process.

Principle of Spot Welding

There are three types of Spot Welding: Resistance Spot Welding, Laser Spot Welding, and Seam Welding.

1. Resistance Spot Welding

Resistance Spot Welding is a method of joining two pieces of metal to be welded by applying electrode rods to them from above and below, applying pressure, and passing a large current through them to cause the base metal to melt and solidify with the heat generated.

When the term Spot Welding is used, it simply means resistance spot welding.

Electrode rods are often water-cooled. It is used to join relatively thin materials and is frequently used in the production of automobile bodies. Welding quality is determined by welding current, as well as energization time, pressing pressure, and material. These conditions must be controlled to improve the quality of the nugget, which is the joint in Spot Welding.

In Resistance Spot Welding, the temperature near the weld zone is lower than that of arc welding, so the effect of heat is limited to a narrow area. Therefore, it is characterized by less deformation and residual stress after welding. On the other hand, because it heats with the heat of high-current electric resistance, the capacity of the welding machine is larger than that of arc welding, which has the disadvantage of higher equipment costs.

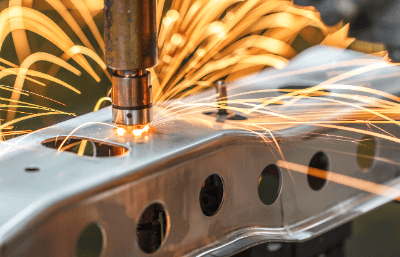

2. Laser Spot Welding

Laser Spot Welding is a method of heating base metal by irradiating it with a laser. Heating is done on one side only, and it is mainly used for welding small, thin objects or objects that require high precision.

Compared to Resistance Spot Welding, the heating time is very short for high power. This has the advantage of minimizing weld distortion.

3. Seam Welding

This is a method of continuously overlapping resistance Spot Welding. It is a type of Spot Welding. The electrode is made in the shape of a roller, sandwiched between two base materials, and heated by rotating the electrode while applying pressure and intermittently passing an electric current. It is used when watertight or airtight is required.

Other Information on Spot Welding

1. Spot Welding in Automobile Production

There are approximately 6,000 welding spots on a single automobile. The welds are made on the body, frame, suspension members, lower arms, etc.

There are many types of welding methods used in automobiles, including resistance welding, arc welding, and laser welding. Nowadays, laser welding is becoming the mainstream in terms of productivity and manufacturing cost.

Among these, Spot Welding is used to weld plate materials such as bodies and pressed doors. Spot Welding used here includes resistance spot welding and laser spot welding.

2. Causes of Spot Welding Failures

Spot Welding uses the electrical resistance properties of metal to perform welding. And there are several causes of defects in resistance welding such as Spot Welding.

- Insufficient joining of plates and other materials resulting from small nugget diameter

Insufficient current flowing from the electrode to the plate or other material due to the tip of the electrode not having the proper diameter. - Insufficient melting or excessive indentation of the joint area of plates, etc.

Caused by the electrode not being symmetrical when it contacts the plate, excessive current flow, excessive pressure, etc.