What Is a Torque Sensor?

Figure 1. Appearance of a Torque Sensor

A torque sensor is a device that measures torque, the force that causes a shaft to rotate, as illustrated in Figure 1.

It converts the slight twist of a shaft under torque into a measurable output, displaying the torque value. Torque sensors are crucial in various scenarios requiring torque measurement, including torque management in production lines and evaluating the performance of industrial machinery.

While it may also be referred to as a torque gauge or torque meter, there are no strict naming conventions. This article will use “torque sensor” consistently regardless of application.

- Torque Sensor

A device used in electric bicycles and robots to control motors or robots based on detected torque. - Torque Gauge

A device for measuring the tightening torque with tools like screwdrivers and instantly checking the torque value on a display. - Torque Meter

A device for assessing motor torque in motor testing setups.

Uses of Torque Sensors

Torque sensors are commonly used in electrically powered bicycles, where they detect the pedal force (torque) applied by a cyclist. The motor then provides the necessary assistance based on this torque, easing the pedaling effort.

In industrial settings, torque sensors are vital in quality control and research testing.

1. Quality Control

Torque sensors are utilized mainly in:

- Spot Checks

Examining how tightly container caps are sealed during production. - Periodic Inspections

Ensuring electric screwdrivers on the production line operate within expected parameters before work commences.

2. Test and Research

In testing and research, torque sensors are mainly employed in:

- Strength Measurement

Assessing test materials and components for torsional strength. - Motor Performance Evaluation

Determining motor performance under various loads. - Rotational Torque Measurement of Machinery

Measuring the torque in machinery, such as rotary printing press rollers, to find optimal operating conditions.

Principle of Torque Sensors

The operation of torque sensors involves the following steps:

- A torque is applied to the shaft.

- This torque induces torsion/strain on the shaft.

- The shaft’s torsion/strain is measured.

- The torque on the shaft is calculated from this measurement.

The measured torsion/strain is converted into an electrical signal, often amplified by an amplifier for easy interpretation and displayed by an A/D converter. Some sensors come with a display for immediate torque reading.

Types of Torque Sensors

Various methods exist for measuring shaft torsion and strain, with the following four being prevalent in current torque sensors:

1. Strain Gauge Type Torque Sensor

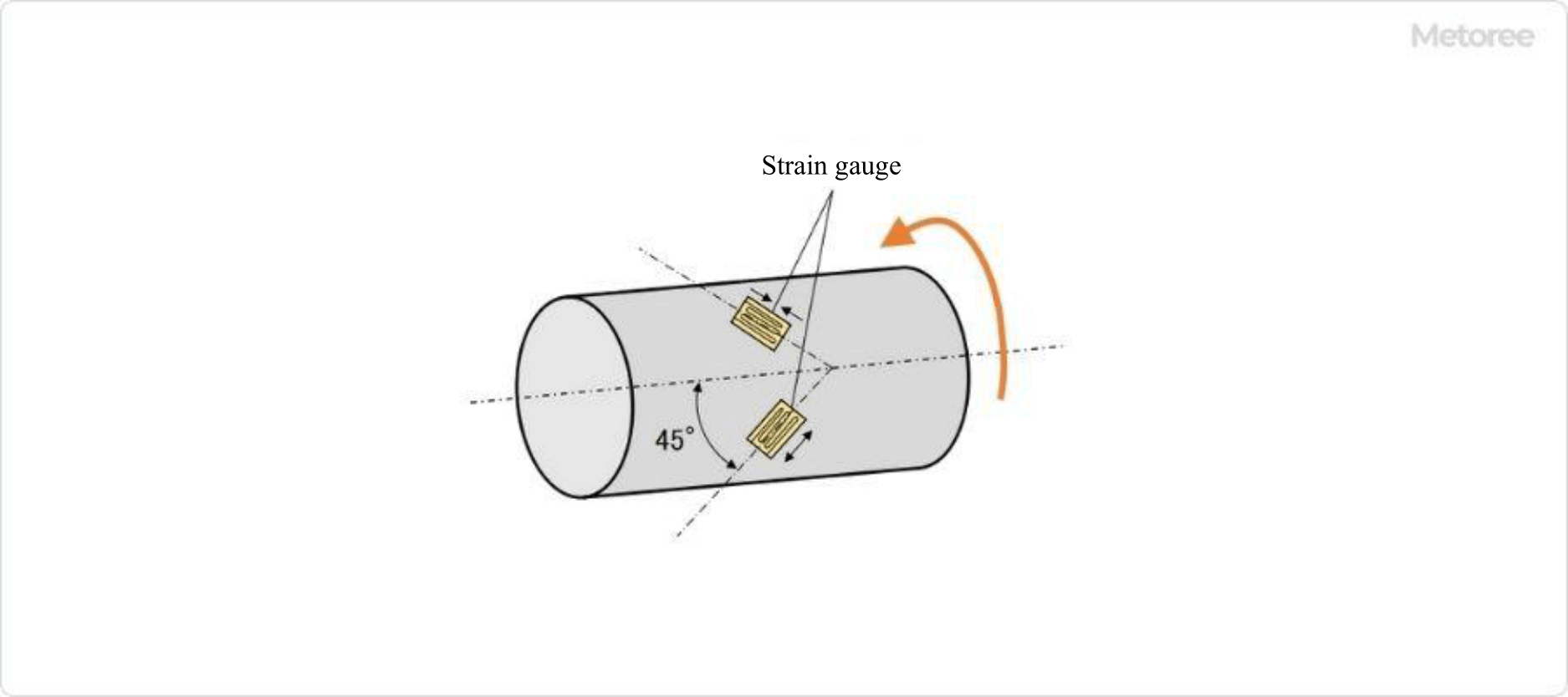

Figure 2. Axis of Strain Gauge Type Torque Sensor

This method employs strain gauges to measure shaft strain due to electrical resistance changes during expansion and contraction. As depicted in Figure 2, tensile and compressive stresses occur at ±45° angles when torque is applied, which is measured by strain gauges.

2. Capacitive Torque Sensor

This method gauges shaft strain through capacitance changes between two electrodes on the shaft, affected by its warping.

Due to its simpler structure and shorter shaft requirement, it’s widely used in robotic torque sensors.

3. Magnetostrictive Torque Sensor

Here, shaft strain is measured by detecting inductance changes in a coil due to the inverse magnetostrictive effect when torque is applied, altering the magnetic permeability.

Advantages include non-contact measurement capabilities, making it suitable for rotating shafts without compromising shaft integrity.

4. Optical Torque Sensor

An optical sensor measures shaft strain by detecting changes in light amount due to emitter and receiver displacement under torsion or distortion.

Other Information on Torque Sensors

Products With Built-in Torque Sensor

Advancements in technology have led to the miniaturization of torque sensors, integrating them into industrial products. Here are examples:

1. Motor With Built-in Torque Sensor

Integrates a motor, reduction gear, and torque sensor for compactness and accurate torque measurement for smoother operation and safety enhancement through human contact detection.

2. Torque Sensor for Robots

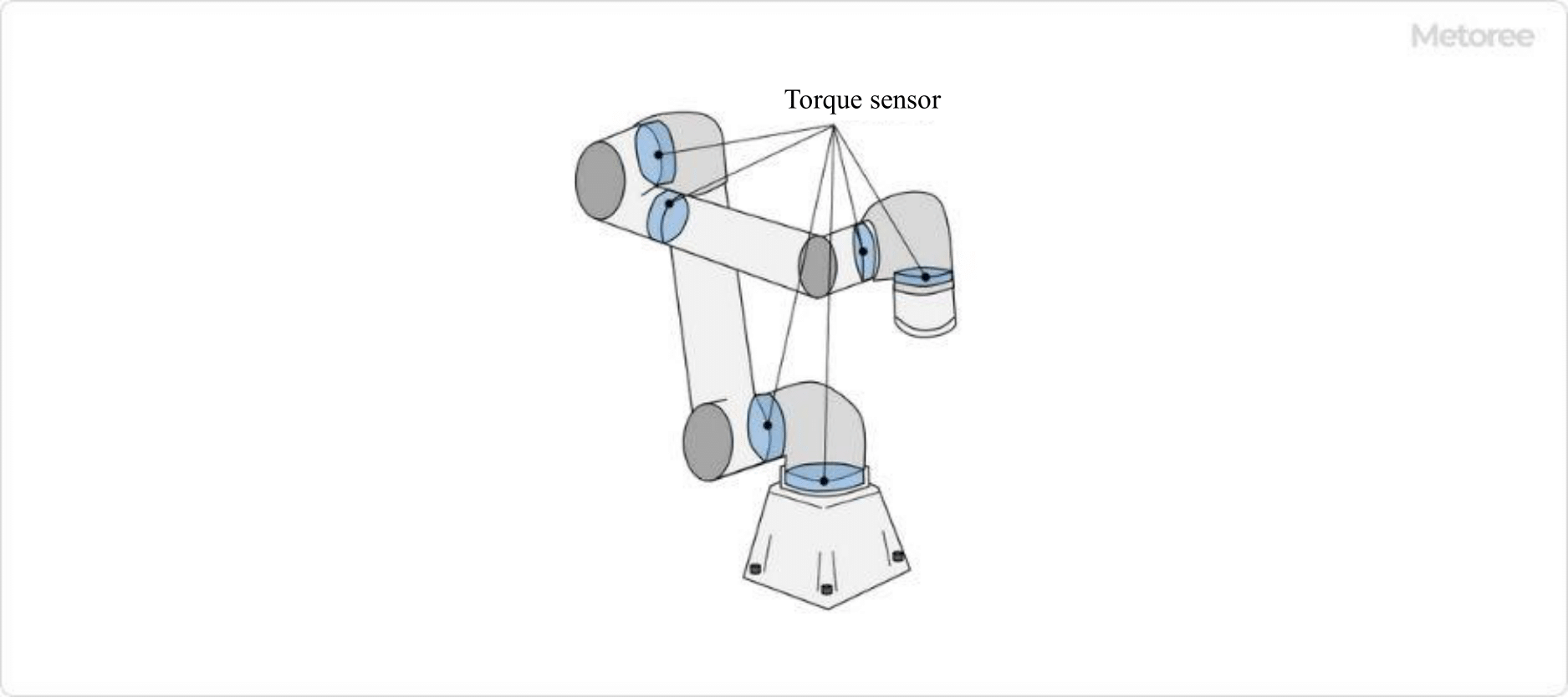

Figure 3. Torque Sensor Built Into the Cooperative Robot

Articulated robots with integrated torque sensors, especially in cooperative robots, enable precise control of force and detection of human or obstacle contact.