What Is a Compressor?

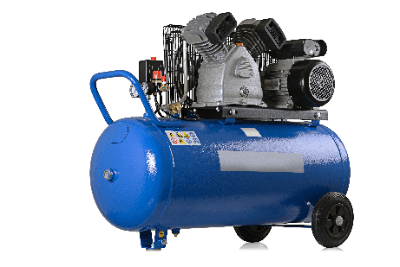

A compressor is a machine that compresses and pumps gas through the rotary motion of a rotor or the reciprocating motion of a piston.

A compressor is a machine that compresses and pumps gas through the rotary motion of a rotor or the reciprocating motion of a piston.

Typical compressed gases include air, hydrogen, and refrigerants. Several methods have been developed to compress air, and selection is based on compression pressure, flow rate, and other factors. When the compression pressure is ultra-high, the risk is extremely high, so it is important to pay close attention to safety.

Uses of Compressors

Compressors are used in a wide range of applications, from home appliances to industrial equipment.

The following are examples of applications:

- Civil engineering work sites and painting

- Instrumentation air production for water treatment plants

- Construction equipment such as stone cutting equipment and pneumatic drills

- Air conditioning equipment such as air conditioners

- Car washing equipment

- Tire inflation

When air is stored in compressors during times when electricity is low and used during times when it is high, it contributes to electricity cost savings.

Principle of Compressors

Compressors can be broadly classified into “turbo type” and “positive displacement type.”

1. Turbo Type Compressor

The turbo type compresses air by giving it kinetic energy. It is further divided into centrifugal and axial flow types.

- Centrifugal Compressors

Centrifugal compressors use an impeller to compress gas in a centrifugal direction. While this type is suitable for larger sizes, it is not suitable for high compression. - Axial Compressor

Axial-flow compressors use rotating blades to compress air flowing in an axial direction. It can handle high compression by stepwise compression and is also suitable for larger sizes. They are also used in jet engines.

2. Positive Displacement Compressor

The positive displacement type compressor compresses by volume change and is further divided into reciprocating and rotary types.

- Reciprocating Compressors

Reciprocating compressors use the reciprocating motion of a piston to compress gas. When the compressed gas becomes higher than the internal pressure of the tank, the check valve opens and the gas is transported to the tank for compression. - Rotary Compressor

In the rotary type, the piston motion of the reciprocating type is replaced by a rotary motion such as a screw. Compared to the reciprocating type, the rotary compressor is characterized by its low noise level.

Other Information on Compressors

1. How to Use a Compressor

Compressors are often used to compress air. In addition, automatic tools are sometimes driven by compressed air from air compressors at construction sites. These automatic tools are called air tools. Depending on the air tool installed, multiple tasks can be automated with air.

Generally, modern compressors automatically control the pressure, but the procedure is as follows:

- Install the air tool before turning on the compressor.

- Power is turned on. If there is no compressed air, the compressor starts up and begins making compressed air.

- When the pressure in the tank rises to the specified pressure, the compressor automatically stops or runs without load.

- The air tool is used to perform various tasks.

- When a certain amount of air is consumed, the tank pressure drops and the compressor restarts or runs again under load.

2. Compressor Oil

A compressor is a piece of equipment that compresses and pumps air or process gas. Compressor oil (lubricating oil) is used to prevent wear and leakage of gases due to contact with the metal piston and screw. Oil should be selected according to the type of compressor.

The oil used in power machinery is specified by the international standard of viscosity ISO VG, according to the application, and the greater or lesser of this value indicates the degree of viscosity. Compressor oil for reciprocating compressors has a viscosity of about VG68, which is slightly high viscosity.

On the other hand, screw type compressors use low viscosity oil to reduce the load on the rotor. There are two main types of oil: mineral oil and synthetic oil. Synthetic oil is used in many compressors because it is less prone to deterioration than mineral oil. Compressor oil must also have excellent resistance to high temperature loading during compression, high-temperature oxidation, and sludge derived from fine particles in the air.