What Is Polyester Powder Coating?

Polyester powder coating is a process for applying powdered paint to a surface. It typically uses three types of powder coatings: isocyanate-cured, primid-cured, and TGIC-cured systems. This method stands out for its eco-friendliness, as it avoids the use of solvents like acetone, reducing environmental and health impacts. Additionally, it allows for the reclamation of unused coatings, enhancing cost-effectiveness.

Polyester powder coatings form strong films, offering excellent corrosion, weather, chemical, and pitch resistance.

Uses of Polyester Powder Coating

Polyester powder coating can create a durable, thick film in a single application, making it suitable for a wide range of uses. Products coated with polyester resin powder paint are robust and versatile, excelling in outdoor settings due to their high strength, hardness, and weather resistance. Common applications include outdoor architectural materials, gardening tools, automotive and electrical components, household appliances, indoor fixtures, fire hydrants, vending machines, and fences.

Types of Polyester Powder Coating

Polyester powder coating involves electrostatically applying and curing powdered paint. There are two primary methods: electrostatic powder coating and fluidized bed coating.

1. Electrostatic Powder Coating

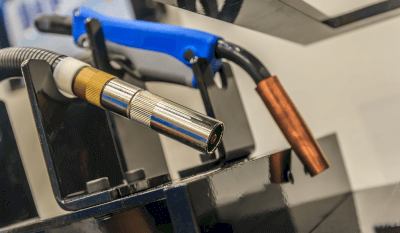

This technique uses a powder coating gun connected to a high-voltage generator, spraying negatively charged powder onto a grounded, positively charged substrate. The attraction between the paint and substrate ensures adherence, with the coating then cured in an oven. This method can create films around 50μm thick, allowing precise control of thickness. It utilizes thermosetting polyester resin known for its chemical resistance, weather resistance, and hardness.

2. Fluidized Bed Coating

In this method, powdered paint is aerated with compressed air. A preheated substrate is then immersed for adhesion, sometimes followed by additional heating. This can achieve film thicknesses of 200-500μm, making it ideal for corrosion-resistant coatings. Thermoplastic polyester powders, such as heat-sensitive polyester, are used for their weather resistance, low dirt susceptibility, and glossy finish.