What Is an Aluminum Can Sorter?

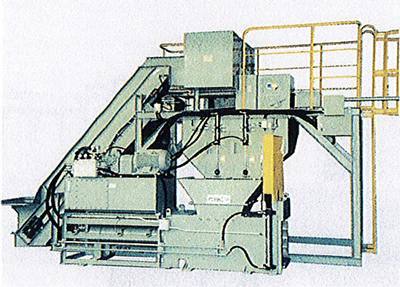

Aluminum can sorters sort aluminum cans, aluminum chips, and nonferrous metals mixed with recyclables such as PET bottles and jars, recycled materials, and shredded waste.

The machine is used to sort and collect aluminum cans, aluminum chips, and nonferrous metals mixed with recyclable resources and recycled materials such as PET bottles and bottles.

At recycling sites for garbage, industrial waste, and home appliances, it separates magnetic materials such as iron from non-metallic materials such as waste paper, waste glass, and waste plastic, as well as non-ferrous metals such as aluminum and copper,

Non-ferrous metals such as aluminum and copper can be separated, sorted, and recovered simultaneously.

Labor costs can be reduced by using automatic sorting machines rather than by sorting each item by hand.

Aluminum Can Sorter Applications

Aluminum can sorters are mainly used in waste and resource recycling plants to sort ferrous, nonferrous, and non-metallic materials automatically. They are used in chemical plants, foundries, and other high-temperature raw material manufacturing plants.

Used in household and industrial waste incineration plants, waste semiconductor recycling lines, waste home appliance recycling lines, aluminum can sorting lines, and waste glass recycling lines.

Nonferrous metal sorting lines from shredded waste from car shredders, carbon black plants for high-temperature raw materials, aluminum recovery from incinerated ash, etc.

The system can be used to automate production and sorting lines. Other applications include garbage collection at train stations and highway service areas, and sorting of nails from pachinko machines.

Principle of Aluminum Can Sorters

Aluminum can sorter is a device that uses eddy currents in a high-frequency magnetic field to sort nonferrous metals. Powerful permanent magnets attached on the circumference of an FRP drum are rotated at high speed to generate a strong alternating magnetic field on the surface of the drum to separate ferrous, non-metallic, and aluminum. Non-ferrous metals such as copper can be separated.

High performance permanent magnet drums rotating at high RPM inside the conveyor belt induce eddy currents in nonmagnetic and nonferrous metals passing over the belt, causing a magnetic field to be generated.

This force acts in opposition to the attractive force, and the propulsive force generated when the conveyor belt is flowing causes non-ferrous metals to bounce off, while magnetic and metallic materials flow directly onto the belt.

Nonferrous metals such as aluminum mixed in the crushed material are sorted out.

The larger the surface area of the nonferrous metal to be sorted, the lighter and more conductive it is, the easier it is to sort.

The aluminum can sorter is also designed to be sturdy and requires little maintenance, allowing for stable sorting over long periods of operation.

Depending on how the permanent magnets inside the rotor are attached, there are eccentric magnet types and concentric magnet types.

Compared to the concentric structure, the eccentric structure has a larger magnetic gradient of the AC magnetic field of the magnetic rotor, which provides superior sorting performance and prevents entrainment of processed materials between the drum and the belt.