What Is a Blackbody Furnace?

A blackbody furnace is a device used to inspect and calibrate devices using infrared rays. The device is placed inside a furnace that imitates a blackbody, which absorbs all wavelengths, and irradiated with light from a reference light source to evaluate its performance without the influence of the external environment.

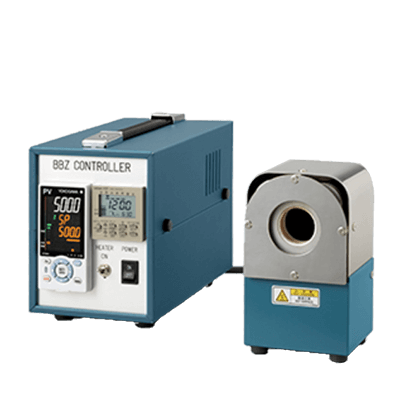

There are two main types of blackbody furnaces: cavity blackbody furnaces, which have a light source in a cavity structure and are suitable for high-temperature measurements; and flat blackbody furnaces, which have a light source made of metal coated with a high-emissivity paint and are suitable for low-temperature measurements or measurements of large objects.

Applications of Blackbody Furnaces

A typical application of blackbody furnaces is the inspection and calibration of non-contact thermometers.

Non-contact thermometers use infrared rays for measurement and require periodic inspection and calibration of the indicated temperature.

The blackbody furnace produces an approximate emissivity of 1, which is the most accurate way to detect temperature, and the difference between the theoretical temperature and the temperature indicated by the measurement device can be checked to confirm the deviation of the measurement device.

Principle of Blackbody Furnaces

Non-contact thermometers determine temperature by measuring the blackbody radiation energy in the infrared region generated by the object. During calibration, it is necessary to compare the temperature with the Planck distribution, a theory that shows the relationship between the intensity of radiation from a perfect blackbody (emissivity 1) and temperature.

In the cavity blackbody furnace, light-absorbing materials such as graphite and carbon nanotubes are used inside the furnace, the temperature inside the device is made uniform, and the shape and surface finish are designed to be easily reflective, so that the radiation energy is multiply reflected to realize simulated blackbody radiation with an emissivity of about 0.99.

By performing tests in this environment with corrections according to the emissivity, it is possible to compare the values of the non-contact thermometer with theoretical values derived from the Planck distribution and calibrate the thermometer.

In the case of a planar blackbody furnace, it is not possible to reflect light multiply, and the emissivity is at most about 0.95 due to the limitation of the paint. Therefore, correction work using a non-contact thermometer calibrated in a cavity blackbody furnace is necessary when the furnace is in use.