What Are Counterboring Services?

Counterboring services are the process of making a hole larger in diameter than the initial hole or screw at the entrance to a threaded or drilled hole.

Counterboring services are the process of making a hole larger in diameter than the initial hole or screw at the entrance to a threaded or drilled hole.

It is a stepped structure when viewed from the cross section. It is used to process metal or wood, and its main purpose is to prevent the bolt head from protruding beyond the mounting surface.

Counterboring Service Uses

Counterboring services are used to prevent bolts and screws from loosening, improve aesthetics, and prevent injury. Specifically, the following types of processing are performed.

- Counterboring services are used to flatten uneven flat surfaces, such as the machined surface of a casting, so that holes can be easily drilled.

- Flattening the contact surface of the bolt washers.

- When installing a screw or bolt, ensure that the head of the bolt does not protrude from the part to which the bolt is attached, so that the flat surfaces of the mating parts can make proper contact.

To install a bolt so that its head does not protrude from the face, use a hexagon socket head bolt or other bolt that does not require a wrench. If the head of the bolt is conical, counterboring services are performed on the edge of the hole to form a conical shape.

Principle of Counterboring Services

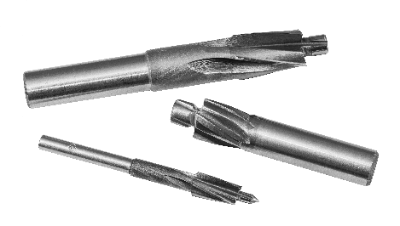

Counterboring services are performed by drilling a hole and then machining it to the desired size and depth with an end mill. There are also counterbore drills that can perform drilling and endmilling at the same time.

A counterbore drill is a drill with a stepped shape. The thin shaft at the tip of the drill is used for drilling holes, and the thick shaft at the base of the drill is used for counterboring services.

Counterboring services must be performed by using a counterboring drill of a shape that allows the desired drill hole and the counterboring services to be performed by passing the counterboring drill to the desired counterboring depth.

Types of Counterboring Services

Counterboring services can be broadly classified into the following four types:

1. Counterboring

Counterboring is a process that only touches the surface of the hole. This is done to secure the bolt’s tightening force.

2. Deep Counterbore

The depth of the counterbore is specified so that the head of the bolt is hidden. Counterboring services are usually about 1mm deep, but deeper counterboring services are called deep counterboring.

3. Countersunk Counterbore

This is done when using countersunk screws. A conical hole is drilled to match the shape of the screw head. Some sites call this process “flat firings.”

4. Back Counterboring

Counterboring services are performed on the opposite side of the thread direction.

Other Information on Counterboring Services

Points to Keep In Mind When Counterboring Services Are Performed

The following points should be noted when performing counterboring services.

Area Required for the Process

The distance from the edge must be considered for the location of the counterbored edge. If the distance between the edge and the radius of the counterbore is almost the same, a thin stepped shape will remain, which is undesirable in use.

Tools

There is a special tool for counterboring called a counterbore drill. It has a narrow, stepped tip and is capable of simultaneous counterboring services and drilling in a single rotation. The counterbore drill is mounted on a drilling machine.

For back counterboring, in which counterboring is done from the opposite side, use a tool with an eccentric tip that protrudes on one side. The structure is such that the tool does not interfere with the first drilled hole when inserted.

Machining Machine

A drilling machine, milling machine, or lathe is used as the processing machine.