What Is a Tapping Service?

A tapping service is a process used to form a female thread in a part into which a screw is to be screwed.

A tapping service is a process used to form a female thread in a part into which a screw is to be screwed.

Using a tool with an uneven profile called a tap. The tap is inserted into a pre-drilled hole to form a female thread.

Uses of Tapping Services

Tapping services are widely used for metal parts that are to be fastened with screws. Threaded fasteners are used in a wide variety of industrial machinery, buildings, and household appliances. Tapping service is required to form the female threads of the part to be threaded.

In addition to tapping services, there are several other methods of forming female threads. Tapping service is one of the most widely used methods. Tapping services are often used to form relatively small-diameter female threads in particular.

Principle of Tapping Services

Tapping services can be performed in two major ways. One is to cut a pre-drilled hole to form a female thread, and the other is to form the thread shape by plastic forming. In either case, tapping services requires a pre-drilled hole and the diameter of the pre-drilled hole must be correctly finished.

1. Cutting Tapping Services

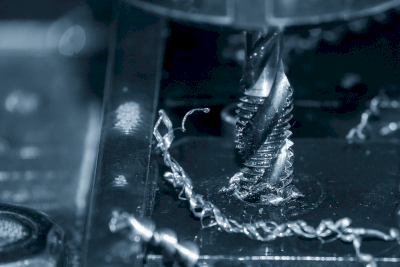

Cutting tapping services is performed by turning with a lathe or milling with a milling machine. Cutting tapping services involves the cutting of metal, which results in the generation of chips.

The advantage is that relatively little torque is required during machining, but care must be taken to remove the chips. Especially when tapping services is performed on a non-through hole called a stop hole, it is necessary to select a spiral tap that discharges the chips to the front side.

2. Rolling Type Tapping Services

Threading is performed while deforming the material using a thread rolling machine. Since it is plastic deformation, not cutting, no chips are generated. However, the diameter of the hole must be more precise than that of the cutting type.

Although tapping services requires more torque than cutting tapping services, it is suitable for mass production because no chips are generated and the machining time is shorter than that of cutting tapping services.

Also, since the fiber flow (metallurgical flow) is not cut, high-strength female threads can be produced. The disadvantage is that the initial cost of tapping services is higher than that of cutting tapping services because it requires the preparation of taps that matches the shape of the desired female thread.

Types of Tapping Services

The following types of tapping service are available. It is important to select one according to the type of the intended female screw.

1. Hand Tap

This is a tap with a straight groove shape. Tapping services can be performed manually by using a hand tap. Since it takes time to process, it is used for purposes such as repairing prototypes and quit screws. Hand taps are available from No. 1 to No. 3, which are used in turn for tapping services.

2. Spiral Tap

The outer circumference of the tapping services is processed in a spiral shape, and during tapping services, the facets are discharged in the opposite direction. Choose a spiral tap when you do not want to eject the chips in the direction of travel, such as in a stop hole.

To ensure that the facets are ejected correctly, use a spiral tap with a right-hand thread with a right-hand thread and a left-hand thread with a left-hand thread. Since the facets are ejected in the direction of the taproot, it is easy for the facets to become entangled in the tap, and if tapping services are performed with the facets entangled, the threaded hole will widen.

3. Point Tap

Point taps have a groove called a point groove and are characterized by low cutting torque, which reduces stress caused by chips. Unlike spiral taps, chips are ejected in the direction of travel, so point taps are mainly used for through holes. However, they can also be used for tapping services for stop holes, as long as the hole is deep enough and the chips are ejected in such a way that they do not damage the threads.

4. Roll Tapping

Roll taps are used in rolling tapping services. It is especially applied to threaded holes in soft materials such as rolled aluminum.

Since it is a rolling process, no chips are generated, and the tapping services time is shorter than that of cutting tapping services. Also, the durability of the tool is high. Since no facets are generated, there is no waste of material, making it an environmentally friendly machining method.