What Are Cascade Pumps?

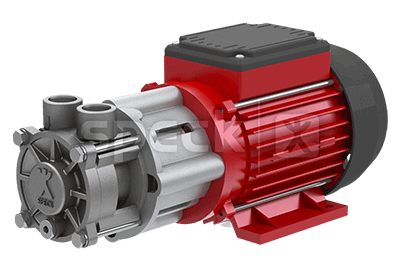

Cascade pumps are pumps with radial grooves (protrusions) on the periphery of the internal impeller.

The centrifugal force generated by the pressure of the vortex flow and rotation on the pump’s inner wall allows the pump to pump a small amount of fluid under high pressure. Cascade pumps are a type of non-displacement pumps and are also called “vortex turbine pumps.”

Cascade pumps are characterized by their ability to produce high pressure even when the flow rate of the liquid to be pumped is small.

Applications of Cascade Pumps

Applications of cascade pumps include raising well water for domestic use and degassing pumps used inside dialysis machines for medical use. Cascade pumps have a higher discharge pressure than volute pumps, which are common pumps, allowing them to discharge relatively low flow rates.

Therefore, they are good at pushing up low-viscosity liquids. The most familiar type of low viscosity liquid is water. Water is often used at home, but not in large quantities at a time.

Therefore, cascade pumps are used for well water, filter filtration, and cooling/temperature control equipment that pumps a large amount of liquid through small pipes.

Principle of Cascade Pumps

Cascade pumps form a vortex by the pushing force of the rotating impeller and centrifugal force through the radial grooves on the periphery of the internal impeller, increasing the pressure. This makes it possible to secure a large amount of pressure to transfer a small amount of liquid.

The impeller inside cascade pumps has numerous small protrusions (radial grooves). These small protrusions allow the creation of a vortex that is stronger than that of a normal impeller. The impeller is repeatedly rotated by the force of the magnet, and by the time the liquid reaches the outlet, it is pressurized and pushed out with a powerful pressure.

Cascade pumps can be further pressurized by squeezing the valve on the outlet side. Cascade pumps, which can push up liquid at high pressure even in small quantities, are also characterized by the fact that the impeller used in general rotates using the power of a permanent magnet, so its rotational power is not inferior due to wear or lack of power.

Other Information on Cascade Pumps

1. Differences Between Cascade Pumps and Volute Pumps

A pump that is often compared to cascade pumps is the volute pump. They are both non-displacement pumps and have the same impeller inside, but the difference between them is the presence or absence of radial grooves (protrusions) on the periphery.

For this reason, cascade pumps have less flow fluctuation due to pressure changes, and their predictive curves, one of the performance indicators of pumps, are higher than those of volute pumps, allowing cascade pumps to have a larger head at lower flow rates.

Another disadvantage of volute pumps is that the pump itself tends to be large due to the larger impeller volume in a multi-stage configuration. To overcome this problem, some manufacturers have made cascade pumps with cascade impellers to give that feature to cascade pumps.

2. Cascade Pumps for Dialysis

Cascade pumps are also used in medical devices for dialysis for kidney failure patients. In medical devices for dialysis, the dialysate solution is heated to around 37° C, which is equivalent to body temperature, so the pressure may be negative.

If the dialysate is not degassed, oxygen and other substances in the solution become supersaturated, which induces the generation of bubbles. If these bubbles adhere to the filtration membrane for dialysis, the efficiency of dialysis is reduced, which is undesirable.

In addition, bubbles can be dangerous if they migrate to the patient’s bloodstream. Therefore, cascade pumps are widely used for degassing the solution under negative pressure, as they have a high head and excellent operational reliability. In medical equipment for dialysis, pressurized pumps are used not only for degassing but also for raising the suction pressure on the drainage side to a constant pressure.