What Is a Cam Follower?

Cam followers are components that reduce the contact resistance between the cam and the linkage in a cam mechanism that converts the direction of motion.

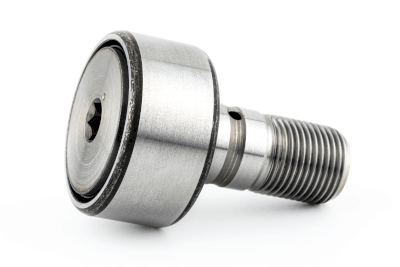

Cam followers are characterized by a stud (screw) on the inner ring of the bearing. These studs are used to attach cam followers to linkage components. A cam mechanism is a mechanism for changing the direction of motion.

For example, it converts the rotational motion of a cam into the linear motion of a link, or conversely, linear motion into rotational motion. A widely used example is the gasoline engine of a car. The engine has multiple cylinders, and a cam mechanism is used to obtain the linear motion from the rotational motion of the engine output shaft to open and close the intake and exhaust valves that intake the air mixture into the piston chamber and exhaust the gas after combustion out of the piston chamber in each cylinder.

Cam followers are attached to the contact point between the cam and the linkage and are necessary for the two parts to move in smooth contact with each other.

Applications of Cam Followers

Cam followers are used in cam mechanisms on a wide variety of machines. Basically, they are often installed inside machines that incorporate elements of rotation.

In addition to cam mechanisms, they are also used as linear guides for smooth, straight-line motion over rails and other surfaces, or as conveyor rollers to move products or loads even with light force as they roll over the rollers.

Linear guides are used not only in industrial machinery but also in copiers, printers, and other office automation equipment where paper is fed or scrapped. When cam followers are used in linear guides or roller conveyance, they are also called roller followers.

Principle of Cam Followers

This section describes the case of a cam mechanism that converts rotational motion into linear motion. A cam is attached to a rotating shaft and is a component with a shape other than a circle. When the cam rotates, if the end of the cam is continuously observed at a point outside the cam, the end will make a certain reciprocating motion at the observation point due to the difference in distance from the cam’s center of rotation.

At this observation point, the cam followers attached to the link are in constant contact with the cam, allowing the link to make a linear motion. At this conversion point between rotational and linear motion, Cam followers play a role in preventing excessive friction between the two parts.

Specifically, friction is greatly reduced by the rolling motion of the needle inside the cam followers. Since the structure is the same as that of a needle bearing, it can also support large loads.

Other Information on Cam Followers

Precautions for Handling Cam Followers

1. Do Not Directly Tap on the Brim When Installing Cam Followers

When installing cam followers, do not give any impact, especially to the brim. The mechanism of cam followers is a needle bearing.

When subjected to a large impact load, the rolling surfaces may be damaged, resulting in premature failure.

2. Install in the Proper Position

Cam followers have oil holes to lubricate the needles. Cam followers should be installed so that the oil hole is on the opposite side of the load area.

Installing the cam followers so that the oil holes are in the load area may shorten the life of the cam followers.

3. Install So That the Studs Do Not Loosen

Cam followers, like needle bearings, are used under heavy loads and must be securely fastened. Cam followers are usually cantilevered on a component with a stud threaded into it.

If the stud loosens and the support shaft becomes unstable, the needle is also subjected to unbalanced loads. It is important to ensure that the studs do not loosen while the machine is in operation. To prevent loosening, inserting washers or securing with double nuts are effective methods.