What Is a Hook Wrench?

Figure 1. Hook wrench

As the name suggests, a hook wrench is a wrench whose tip is shaped like a semicircular hook.

There are many other names for hook wrenches, such as “hook wrench,” “hook wrench,” “pin wrench,” “ring wrench,” “lock ring wrench,” “S-shaped head wrench,” “coil-over wrench,” and “slotted nut wrench.”

Usage of Hook Wrenches

Hook wrenches are used to tighten or loosen special slotted nuts. Special grooved nuts have various names such as “grooved round nut,” “nut for bearing,” “bearing nut,” “lock seat,” “spring seat,” “lock ring,” “lock nut,” “stem nut,” “slotted nut” and “castle nut.”

They are mainly used in the maintenance of automobiles, motorcycles, and bicycles. It is a specialized tool indispensable for adjusting vehicle height, suspension, steering, seats, etc.

Principle of Hook Wrenches

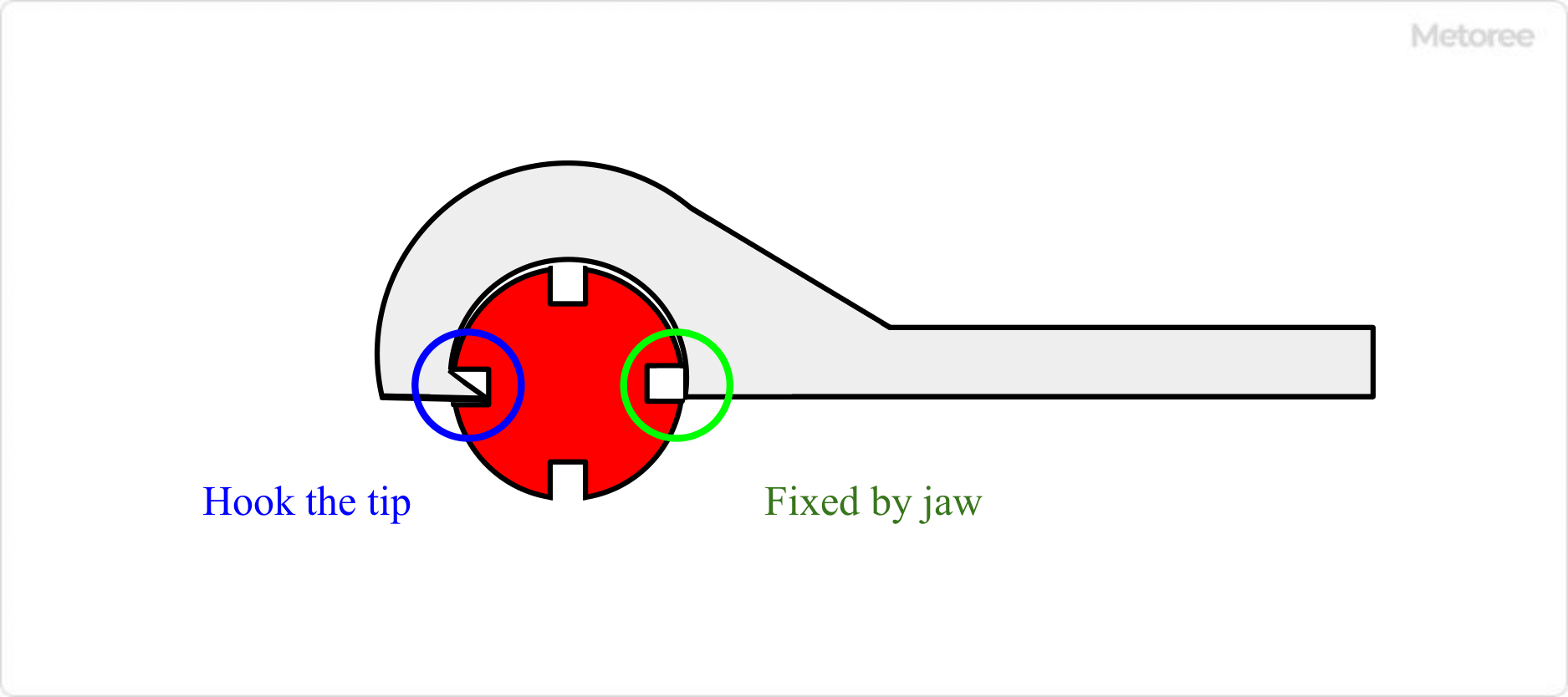

Figure 2. Hooking and fixing the hook wrench

The hook wrench hooks the tip of the hook into the groove of the nut and fixes the nut firmly with its jaws, so that it can be tightened or loosened with torque. It is important to select the right size of hook wrench because it is impossible to apply force if it cannot be hooked and secured.

If you do not have a hook wrench, you can grab it with water pump pliers or other tools, or you can put a flat-blade screwdriver on the groove and hit it from behind with a hammer. However, it is recommended to use a hook wrench as much as possible because it does not apply enough torque and damages the nut.

How to Select a Hook Wrench

The following five points should be considered when selecting a hook wrench.

1. Size

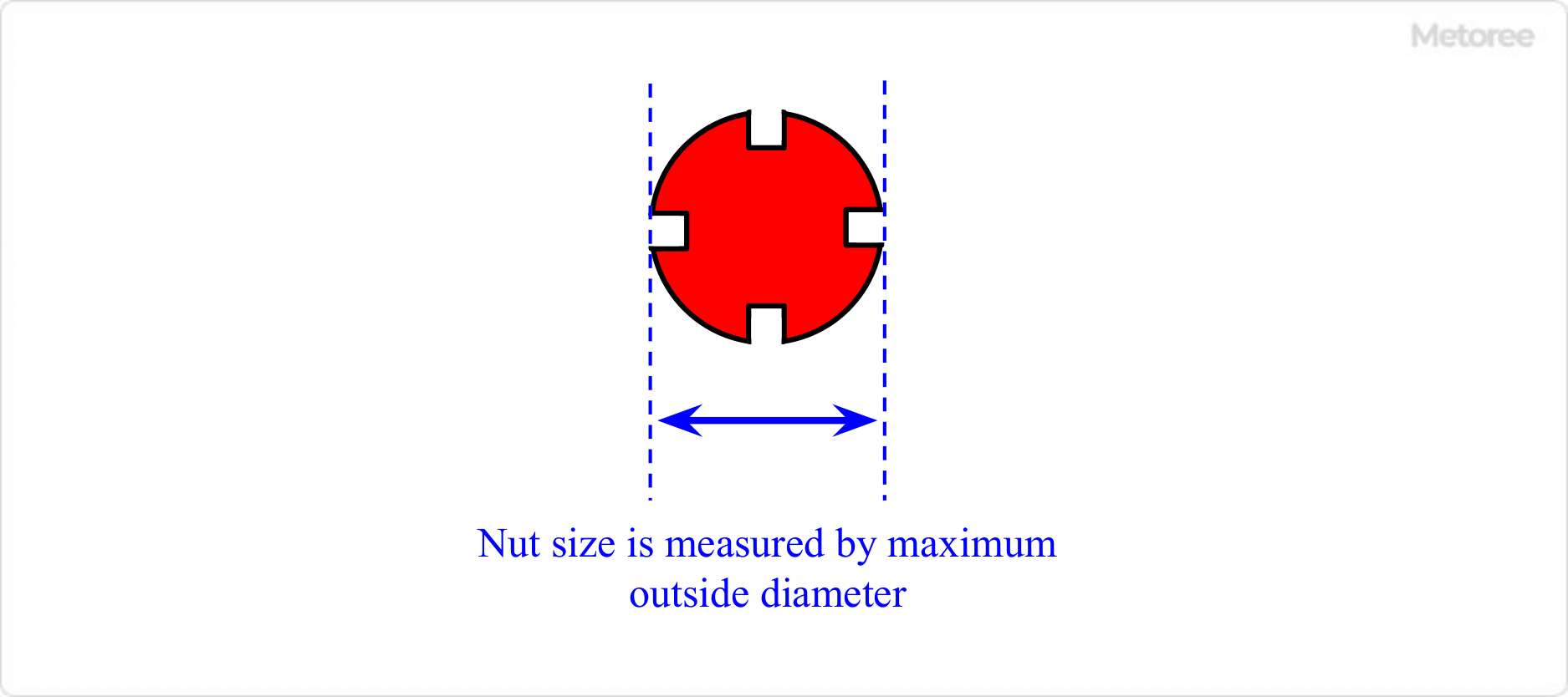

Figure 3. Nut size is measured by maximum outside diameter

If the hook wrench is not the correct size, it cannot be used because it cannot be hooked into the groove of the nut to fix it in place. When purchasing a hook wrench, it is recommended to measure the nut size. Note that the nut size is not the inside diameter (inside the groove), but the maximum outside diameter.

The size range is specified as “25-30 mm,” “30-38 mm,” and so on. Nuts within the range can be worked.

2. General Type and Adjustable Type

There are two types of hook wrenches: general type and adjustable type.

General Type

The general type is simple, easy to use, and difficult to break. If the size of the nut to be worked on varies, it is necessary to prepare a hook wrench for each size.

Adjustable Type

Adjustable type hook wrench is a hook wrench that can be adjusted in size. It is called “adjustable hook wrench,” “universal hook wrench,” or “adjustable hook wrench.” There are various types of size adjustment, such as sliding type, worm gear type, and open/close type.

The applicable range is wide, such as “25 to 70 mm” and “35 to 105 mm,” and it is convenient because one wrench can cover almost all nuts. However, unlike the general types, these nuts have movable parts that may break if too much force is applied.

3. Hook Type and Round Pin Type

There are two types of hook wrenches: one with a “hook type” tip (jaw) and the other with a “round pin type” tip (pin). Generally, most nuts have a groove, so the hook type will work fine.

Some nuts have round holes instead of grooves, in which case a round pin type hook wrench is required.

4. Thickness of Hook Wrench

The thickness of the hook wrench should also be noted. Inexpensive and flimsy ones may bend as you use them.

In particular, since nuts are often adhered to, a sturdy one that does not bend even when large torque is applied is better. Durable ones will be more expensive, but they are more economical in the long run because they are less likely to bend and have to be repurchased.

Also, the thicker the wrench, the easier it is to grip and apply force.

5. Insert Angle for Torque Wrench

Some hook wrenches have a square hole for a torque wrench. If you need to control torque, a hook wrench with an angle is the best choice.

The hook wrench can be equipped with a spinner handle (long handle) as well as a torque wrench, which is useful for loosening nuts that are sticking.