What Is an Ultrasonic Cutting Service?

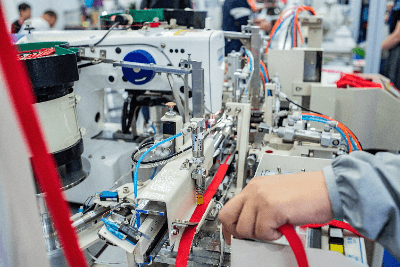

An ultrasonic cutting service is a method of cutting workpieces by applying ultrasonic vibrations to cutting tools such as knives.

An ultrasonic cutting service is a method of cutting workpieces by applying ultrasonic vibrations to cutting tools such as knives.

The occurrence of burrs, chips, cracks, etc. is greatly reduced, as well as the formation of altered layers and machining distortion, resulting in improved machining accuracy. In addition, machining time can be shortened and tool life can be extended due to reduced machining resistance.

Ultrasonic cutting service facilitates the cutting of resin products, rubber products, non-woven fabrics, layered composite materials, and food products such as cakes, which are difficult to cut with ordinary cutters.

Uses of Ultrasonic Cutting Services

Ultrasonic cutting service can cut hard metals and ceramics as well as cakes that easily lose their shape. It cuts hard-to-cut carbon fibers, polishes molds smoothly, and even cuts ultra-fine patterns on printed circuit boards.

Using the high-frequency vibration of ultrasonic cutting service, it can cut carefully and with high precision. Thus, it is ideal for cutting hard, brittle materials such as ceramics, glass, and jewelry. Since no heat is generated and a clean cross-section is obtained, it can be used for cutting resin.

Ultrasonic cutting services can also be used to cut fine electrical contacts, such as in circuit boards, batteries, and power devices. Furthermore, ultrasonic cutting services are expected to be utilized for lithium-ion batteries.

In the food industry, it can be used as an ultrasonic food cutter to cut cakes and other confectionery items that may lose their shape. The ultrasonic cutting service produces a clean cutting surface due to the fine blade movement caused by ultrasonic vibration.

Principle of Ultrasonic Cutting Services

Ultrasonic cutting services are mainly used for cutting packaging materials, non-woven fabrics, and sheet materials. Ultrasonic cutters, which vibrate at high speeds, prevent food, rubber, and sheet materials from sticking to the cutter, thereby contributing to faster processing, less product material, and lower energy consumption.

The device that performs ultrasonic cutting service is called an ultrasonic cutting machine and consists of an oscillator and a transducer. The oscillator emits ultrasonic signals at 15,000 to 40,000 Hz, and the transducer applies ultrasonic vibration to the workpiece. The oscillator is generally equipped with a function to maintain a constant amplitude to ensure constant sharpness at all times.

When an ultrasonic signal from the oscillator is given to the piezoelectric element made of ceramics, the piezoelectric element stretches and contracts to generate ultrasonic vibrations. A blade tool is fixed to the oscillator, and the ultrasonic vibration of the blade cuts the workpiece. The blade, called a horn at the tip, functions to amplify the vibration efficiently. Continuous vibration of about 100μ at both amplitudes is possible.

Objects have natural frequencies, and when an external force synchronized with that frequency is applied, even a small external force will cause a large vibration. This is resonance. Ultrasonic cutters use resonance to cause the cutting edge to vibrate significantly.

Other Information on Ultrasonic Cutting Service

1. How to Select an Ultrasonic Cutting Service

Because of the wide variety of ultrasonic cutting machines available, the choice should be based on the application. For example, food cutters can cut soft breads and cakes without losing their shape, and the circular blade allows continuous cutting. Other useful functions to ensure the same sharpness at all times are oscillators of a constant amplitude type.

There are two ways to cut food: one is to use oscillating force to cut by dragging the blade, and the other is to use impact force by swinging it down and striking it. The oscillating method is used when the blade is knife-shaped, and the impact method is used when the blade is guillotine-shaped.

The selection of a small handy type ultrasonic cutter is based on the following four points: first, whether it is an inexpensive and handy type for hobby use or an expensive and high-performance type for industrial use; second, whether the switch is located on the oscillator, transducer, or foot pedal; third, whether it is equipped with a TAF circuit (automatic adjustment function); and fourth, whether it has a replacement blade. The fourth is whether the machine comes with a blade or whether replacement blades are readily available.

2. Advantages of Ultrasonic Cutting Services

Improved Processing Accuracy

Even flexible workpieces such as sheet materials can be processed with high accuracy due to low deformation distortion.

Reduction of Chips, Burrs, and Cracks

Since cutting is performed using minute vibrations, there are fewer chips and burrs.

Reduced Processing Resistance

Since machining resistance is reduced, transformation and machining strain due to machining are reduced, and tool life is extended.

Reduced Machining Time

Ultrasonic waves have a higher frequency, resulting in faster machining speeds.

Extremely Clean Cut Surfaces

Cutting is performed with minute amplitude, resulting in smooth cut surfaces.

Reduction of Defect Rate

Stable cutting process is possible with repetition of a small amount of processing.

Ideal for Cutting Food Products

No food residue or shavings, which can be a problem with rotary blades, etc., are produced, making the cutting process hygienic.