What Is a Resin Bearing?

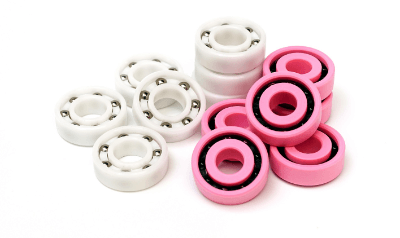

A resin bearing is a bearing fabricated from a plastic material.

A resin bearing is a bearing fabricated from a plastic material.

Resin bearings are also called plastic bearings. A bearing is a component that receives the rotating shaft of a rotating device and facilitates its rotation.

Since resin bearings are made of resin, they are lightweight and can be molded freely. They have high resistance to heat and chemicals, as well as high insulation properties, and can be used in special environments where metals are unsuitable.

Another advantage is that they do not require oil grease or other lubricants, so they require less frequent maintenance. The materials used for resin bearings are mainly synthetic resins, and since there are a wide variety of materials, the optimum material can be selected according to the application.

Uses of Resin Bearings

Resin bearings are used in a wide range of applications, from furniture and other household goods to industrial and commercial equipment. Specific applications are as follows:

- Furniture and refrigerators used in offices

- Electrical appliances such as vending machines

- Steel furniture and bicycle parking equipment

- Food factories that do not want to use grease

- Chemical plants that use chemicals

- Rotating shafts of motors and pumps for submersible pumps

Compared to metal bearings, resin bearings have superior chemical and water resistance, and are used in chemicals and underwater because they are non-conductive.

Principle of Resin Bearings

Bearings are made of metal, but resin bearings are made of resin. Resin has excellent corrosion resistance, water resistance, and insulation properties, is lightweight, and can be manufactured at low cost. These advantages are utilized in bearings, which are resin bearings.

Resin bearings are manufactured by using resin materials for sliding parts to effectively demonstrate the characteristics of resin and to design a balance between load and load. Although materials other than resin may be used for the ball portion of a resin ball bearing, the same resin material is generally used for the raceways and cage. The material of each component of the bearing can also be specified according to the intended use.

Other Information on Resin Bearings

1. Disadvantages of Resin Bearings

Bearings can be divided into rolling bearings and plain bearings. In terms of material, they are further classified into metal bearings and resin bearings. Although resin bearings have many advantages over metal bearings, they also have the following disadvantages.

Bearing Strength

Although the performance of engineering plastics is improving, they are not as strong as metal. Therefore, resin bearings cannot be used under heavy loads. Their low strength also results in high deformation, making them unsuitable for high-precision applications.

Heat Resistance of Bearings

Resin cannot be used in high-temperature environments because it softens at temperatures as low as 260°C, even for Teflon materials with high heat resistance. Other disadvantages include difficulty in high-precision machining, difficulty in manufacturing high-precision bearings, and susceptibility to ultraviolet rays and impact loads.

2. Materials of Resin Bearings

There are various types of materials used for resin bearings. For plain bearings, resin materials such as polyacetal and tetrafluoroethylene with fillers and lubricants are often used.

PEEK (polyetheretherketone), PTFE (Teflon resin), and phenolic resin are often used in rolling bearings.

PTFE has excellent heat resistance and chemical resistance, but its best features are a low coefficient of friction and low adhesion. For this reason, it is used for frying pan coatings. Although its mechanical strength is slightly inferior, it does not absorb water and does not swell with chemicals.

Phenolic resin, also called Bakelite, is characterized by its high insulating and oil resistance properties. It is also resistant to chemicals other than alkalis. Prices are relatively low compared to other materials. Many types of materials are available, including those with conductivity added by adding conductive materials and those partially made of metals.