What Is a Surface Tension Meter?

A surface tension meter is a device used to measure the tension (surface tension) that a liquid or solid exerts in an attempt to make its surface as small as possible.

For example, let us assume that a liquid is in a glass. The liquid in the cup is stable because the intermolecular forces between the surrounding molecules attract and cancel each other out, but the liquid on the surface of the cup and the air has a slightly rounded and swollen shape because the intermolecular forces pulling it from the air side are small.

This is surface tension, and the larger the surface tension of the liquid, the larger the expansion. This force is relatively large and is an important physical property in detergents and inkjet printing.

Figure 1. Surface tension

Applications of Surface Tension Meters

A surface tension meter is used in quality control and research and development of detergents, food, solder, etc. They are important in the investigation of wetting of ink-jet and coating materials and solder, as well as in the fields of coating and microfluidics.

Measuring and properly controlling surface tension can change the foaming process and ease of agitation during manufacturing and use, as well as the presence or absence of coating defects. When selecting a Surface Tension Meter, it is important to consider the accuracy of the evaluation, the measurement time, the type of liquid being handled, and the measurement range.

Principle of Surface Tension Meters

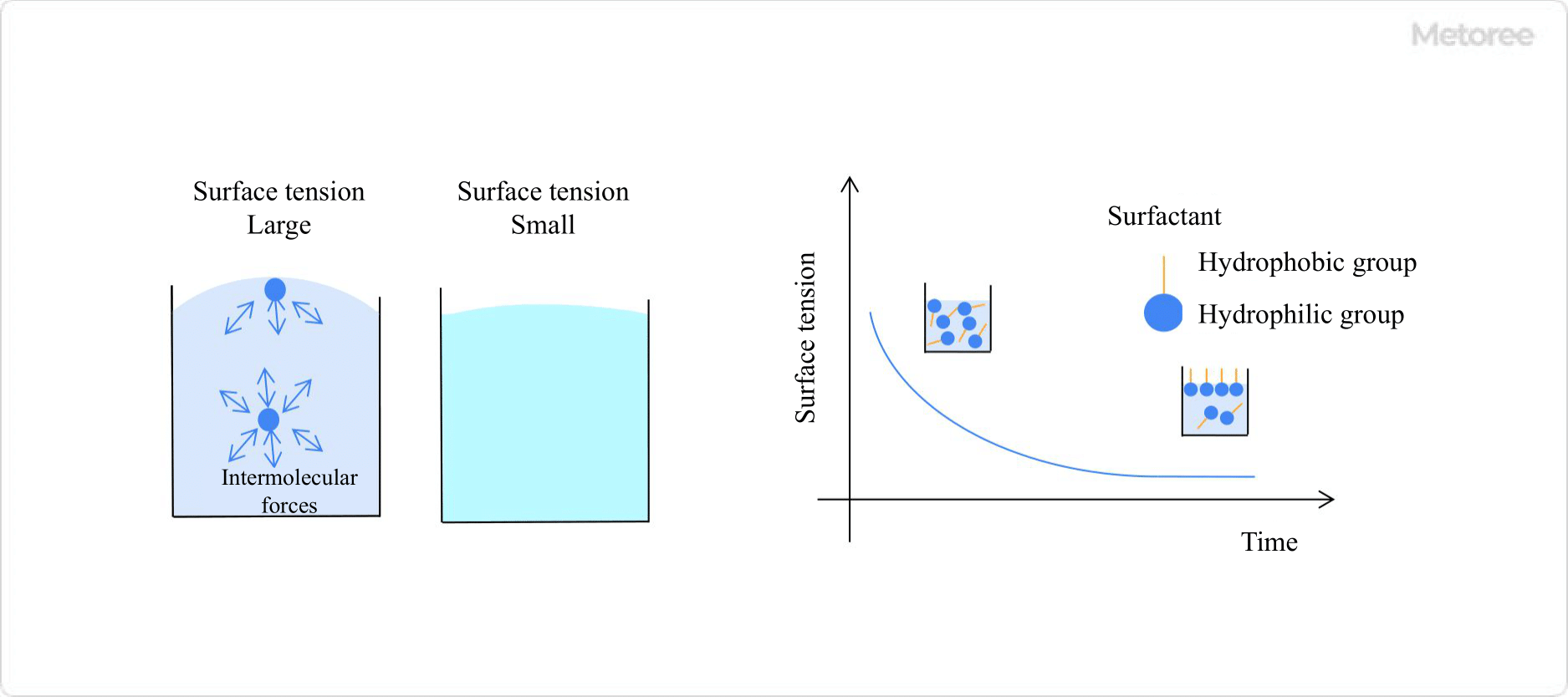

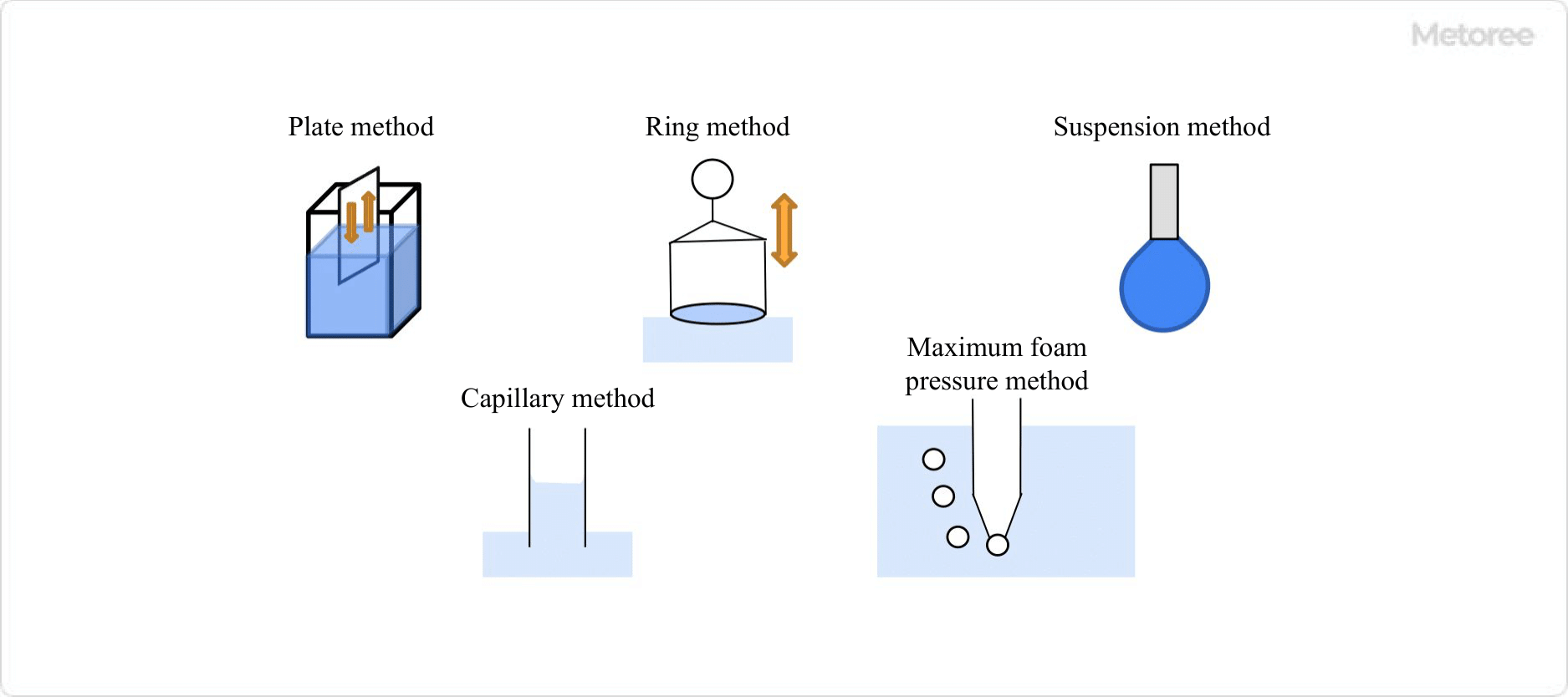

Figure 2. Types of surface tension meters

Many methods have been developed to measure surface tension, including the “suspension method,” which calculates surface tension from droplets, the “plate method,” which measures the force pulled by a plate surface, the “ring method,” which measures the force pulled by a ring in contact with a liquid surface, and the “capillary method,” which measures the height of a liquid rising through a capillary tube.

1. Plate Method (Wilhelmy Method, Suspension Method)

When measuring, the plate is lifted from the state where it is in contact with the liquid to be measured. The force required to lift the plate is measured, and the surface tension is determined from the contact angle between the plate and the liquid to be measured separately and the dimensions of the plate. Even if the contact angle is not known, if the plate is completely wetted, θ is zero and can be measured.

Since it is also possible to measure a plate while it is standing still, both dynamic and static surface tension can be measured. On the other hand, since the plate must be wetted to a certain extent, it is usually necessary to prepare at least 30 mL of liquid.

2. Ring Method

As with the plate method, the ring-shaped measuring device is lifted from the state where it is in contact with the liquid to be measured, and the force required to lift it is measured. Unlike the plate method, the force is monitored at any time and the surface tension is measured using the force when the ring and liquid separate.

It is not possible to measure solutions such as surfactant solutions whose surface tension changes over time. The ring method can also measure lamella length. A lamella is a thin bubble film within a bubble. Longer lamella length means that the bubbles do not disappear even when stretched, and the bubbles remain stable.

3. Suspension Method

This method measures surface tension by fixing the liquid to be measured as a droplet and analyzing the shape of the droplet using equations and other methods. The accuracy varies depending on the performance of the camera and the algorithm used.

This method is suitable for measuring the interfacial tension between liquids such as highly viscous liquids, molten polymers, and oil and water, which are difficult to measure with the plate method.

4. Capillary Tube Method

Surface tension is calculated by measuring the height and density of a liquid as it rises up a capillary tube. The capillary phenomenon is utilized.

5. Maximum Bubble Pressure Method

Gas is poured into a capillary inserted into the sample liquid to generate bubbles. The maximum pressure applied when bubbles are generated (maximum bubble pressure) is measured and the surface tension is calculated.

The time from when a new bubble is generated at the tip until the maximum bubble pressure is reached is called the bubble lifetime, and since the pressure decreases as the surfactant is adsorbed during this time, dynamic surface tension can be measured by testing at various bubble lifetime settings.

How to Select a Surface Tension Meter

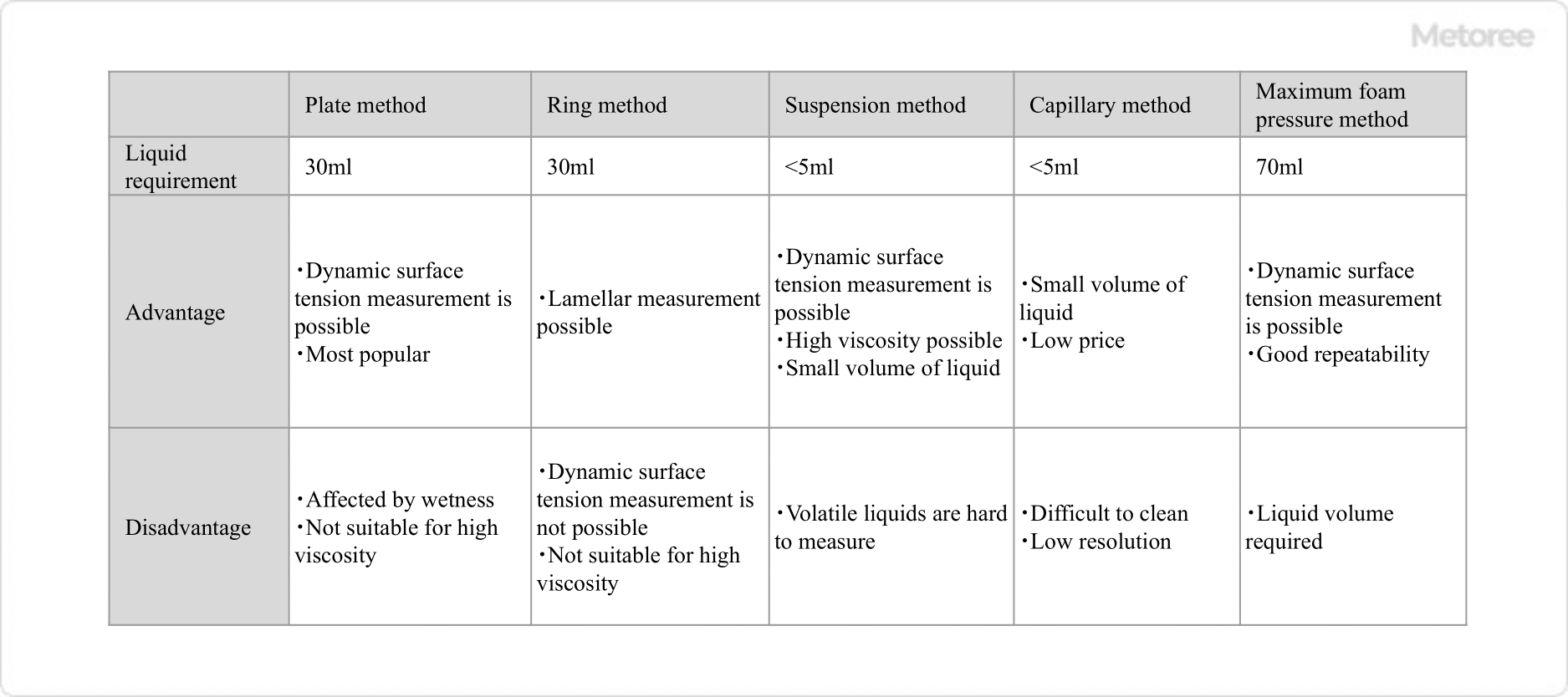

Figure 3.Comparison of surface tension meters

Each surface tension meter has its own requirements and strengths and weaknesses. Select the appropriate surface tension meter by checking the physical properties of the liquid you wish to measure and the amount of liquid you can secure.

Other Information on Surface Tension Meters

Static and Dynamic Surface Tension

Surface tension can be classified into static and dynamic surface tension. Dynamic surface tension is generally greater and decreases over time. This is because surfactants with hydrophilic and hydrophobic groups gather at the gas-liquid interface over time and are adsorbed on the surface.

As the hydrophobic groups gather on the surface of water, the surface tension value goes from a high value for water to a value similar to that of hydrophobic oil. The concentration at a certain surface length force after sufficient time is called the critical micelle concentration, and instruments capable of measuring dynamic surface tension can also determine this critical micelle concentration.