What Is a Precision Cutting Machine?

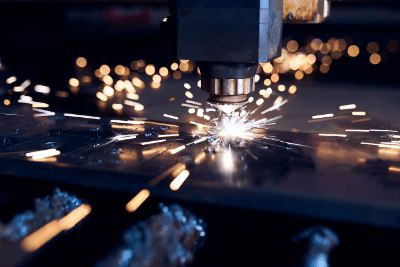

A precision cutting machine is a machine capable of cutting metal with high precision.

A precision cutting machine is a machine capable of cutting metal with high precision.

Precision Cutting Machines use diamonds, CBN wheels (stereocrystalline boron nitride), and other hard materials as irons. The friction surface is not roughened, and specimen pieces free of burrs, burrs, and dust can be produced.

In addition, models equipped with a CCD camera can magnify the cut area on the monitor. This makes it possible to determine the position of the cut surface more precisely, enabling more accurate cutting. Precision cutting machines are widely used in a variety of industries, including the manufacturing of electronic components and semiconductors, automobiles, aircraft, and medical equipment.

Applications of Precision Cutting Machines

Precision cutting machines, as the name implies, are used to cut a wide variety of materials. They are used in a wide range of fields, including metals, ceramics, synthetic resins, minerals, biological samples, and electronic materials, and are also useful for observing the shape of cut surfaces, typically with SEM (scanning electron microscope) or microscopes.

Other applications include the manufacturing industry for electronic components, semiconductors, automobile and aircraft parts, and even medical equipment. As industry demands precision and quality, precision cutting machines are expected to become increasingly important.

A major advantage of using precision cutting machines is that they prevent chipping (the rounding off of the cutting edge of the tines) and cracking (fine cracks in the cut sample). This allows cutting work to be performed while maintaining sample quality.

Principle of Precision Cutting Machine

Precision cutting machines use high-hardness grinding wheels to cut a variety of materials precisely, including metals, ceramics, synthetic resins, minerals, biological samples, and electronic materials. The cut surfaces are generally observed using SEM (scanning electron microscope) or microscopes. Precision cutting machines are used to prevent chipping (rounding off of the cutting edge of the cutting wheel) and cracking (fine cracks in the cut sample).

Precision cutting machines are available in dry and wet types. The dry type cuts directly to the sample, while the wet type cuts without burning by allowing the cutting fluid to penetrate between the sample and the grinding wheel.

High-hardness materials such as diamond and CBN wheels (stereocrystalline boron nitride) are used for the grinding wheels, which give the Precision Cutting Machine its high cutting accuracy. In addition, heat and friction generated during the cutting process are minimized to produce specimen pieces with no burrs, chips, or dust on the cut surface.

Other Information on Precision Cutting Machine

Control Method of Precision Cutting Machine

A precision cutting machine has four control methods depending on the movement of the sample and the grinding wheel: “vertical cutting,” “slide cutting,” “vibration cutting,” and “skip cutting.” In the wet type, cutting fluid enters between the sample and the grinding wheel by vibration.

Materials that are sensitive to heat and easily deformed during processing, as well as complex shapes and hard materials, can be cut. Cutting fluid, also called coolant or cutting oil, comes in two types: water-soluble and insoluble.

Water-soluble cutting fluids are often used due to their ease of cleaning the work environment and their resistance to ignition. Water-soluble cutting fluids are available in emulsion, soluble, and chemical solution types.

Furthermore, variable cutting of grinding wheels, in which the rotation speed of the grinding wheel can be changed according to the hardness of the sample, and circumferential speed controlled cutting of grinding wheels, in which the rotation speed is kept constant, are available. Therefore, the optimal cutting method should be selected according to the hardness and shape of the specimen.