What Is a Desktop Press Machine?

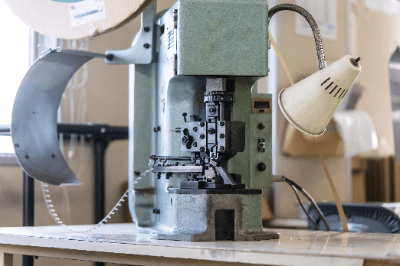

A bench press is a small press machine that is used on a desk.

A bench press is a small press machine that is used on a desk.

Because it is used on a table, it is also called a table press. A material to be processed, such as metal, is placed between the dies of the press machine, and strong pressure is applied to deform the material into the shape of the dies for processing.

It is also used for powder molding and crimping, in which metal or chemical powder is placed in the die and high pressure is applied. The simple structure of this processing equipment allows for easy maintenance, and it has a long service life.

There are various methods of applying pressure, including hydraulic, pneumatic, screw, and crank presses.

Uses of Desktop Press Machines

Desktop press machines are used in the assembly process of production lines and in research and development. High-quality processing that meets specifications can be achieved by changing the method of pressurization and drive, and the size and shape of the die, according to the required processing.

They are used in a wide range of fields, including electronics, small parts, semiconductors, the automotive industry, and the medical and pharmaceutical industries. Taking advantage of their compact and lightweight features, they are used when installation space is limited.

In addition to “kinkage,” in which metal is processed by pressing, they are sometimes used for powder molding and other purposes. It is suitable for repetitive and repetitive work and mass production of the same parts.

Principle of Desktop Press Machines

Desktop press machines are available in two methods of pressurization: manual press by manually turning a handle, and motor-driven press at high speed.

In the case of the manual method, pressure is applied to the pressure receiving plate by turning and tightening the handle. Since the load can be displayed, this type is suitable for working while checking the applied pressure.

In a hydraulic press, pressure is applied by sliding a plunger with hydraulic pressure. By operating the valve for hydraulic adjustment, pressure can be set easily and freely. It is also possible to prevent excessive or insufficient pressure for optimal processing.

Electric presses are also available in mechanical types that use a crank, pneumatic types, and screw types.

Types of Desktop Press Machines

1. Manual Type

Manual crank-type presses are mechanical presses that use a crank. They are used for tablets and compression. For tablets, it can press various granular crystals and well-flowing powder materials into tablets.

Crank presses are suitable for small batch production and research laboratory applications in pharmaceutical and healthcare products, food, agriculture, chemical industry, electronic batteries, metallurgical ceramics, and other industries.

Manual hydraulic presses use hydraulic pressure to compress. They are used, for example, to prepare specimens for X-ray fluorescence analysis or infrared spectroscopy.

2. Motor-Driven

Rotary Press Machine

A rotary press is a machine that rotates rollers and produces tablets by the up-and-down motion of a compression plunger. Continuous production is possible.

Hydraulic Press Machine

Hydraulic presses are machines that press using hydraulic pressure. The applied pressure can be set freely by a simple operation of the hydraulic adjustment valve. They are used for press fitting, crimping, and pharmaceutical production. Automation is possible.

Pneumatic Presses

Pneumatic presses are relatively simple machines that press by air pressure. Pneumatic presses can be used for press fitting, press fitting, punching, bending, drawing, and other processes.

Crank Type Press Machine

Crank-type presses are mechanical compression machines that use a servomotor to drive a crank. It is suitable for mass-production stamping of small precision parts.

Screw Press Machine

Screw press machines are press machines that can make precise positional adjustments by rotating a screw. They are especially used for small-volume prototyping and processing experiments.